Steel-plastic composite pipe with bridge type framework

A steel-plastic composite pipe and skeleton technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of shortened service life, increased cost, structural damage of steel pipes, etc., and achieves good flame resistance and thermal insulation, The effect of reducing liquid impact noise and combining steel and plastic with a firm seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

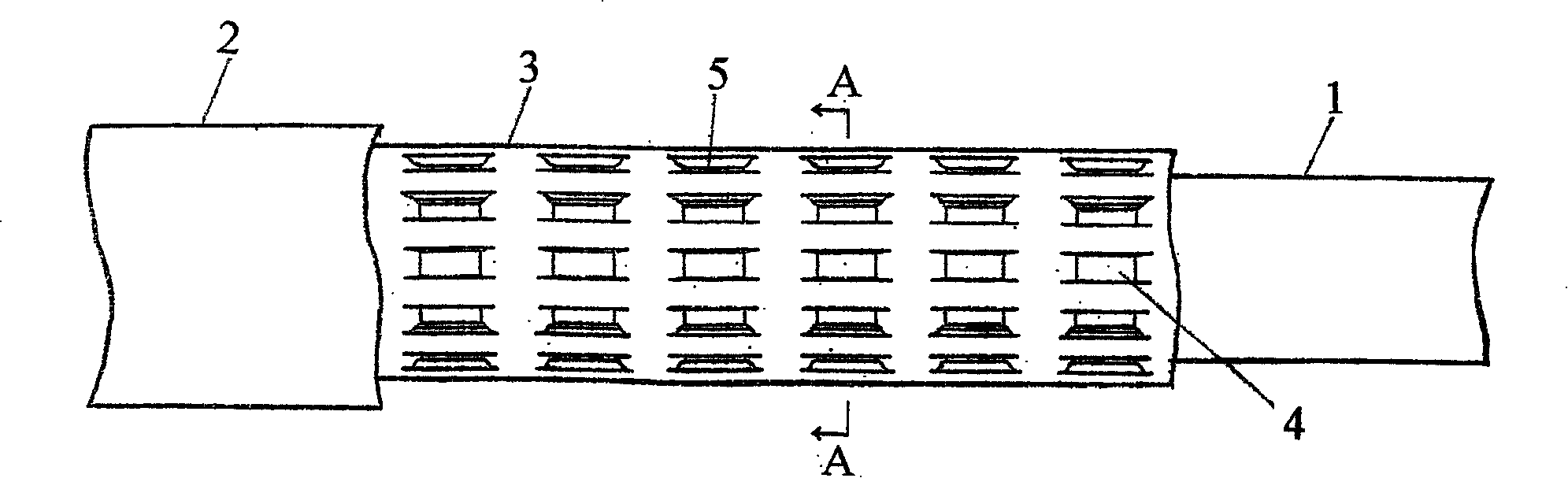

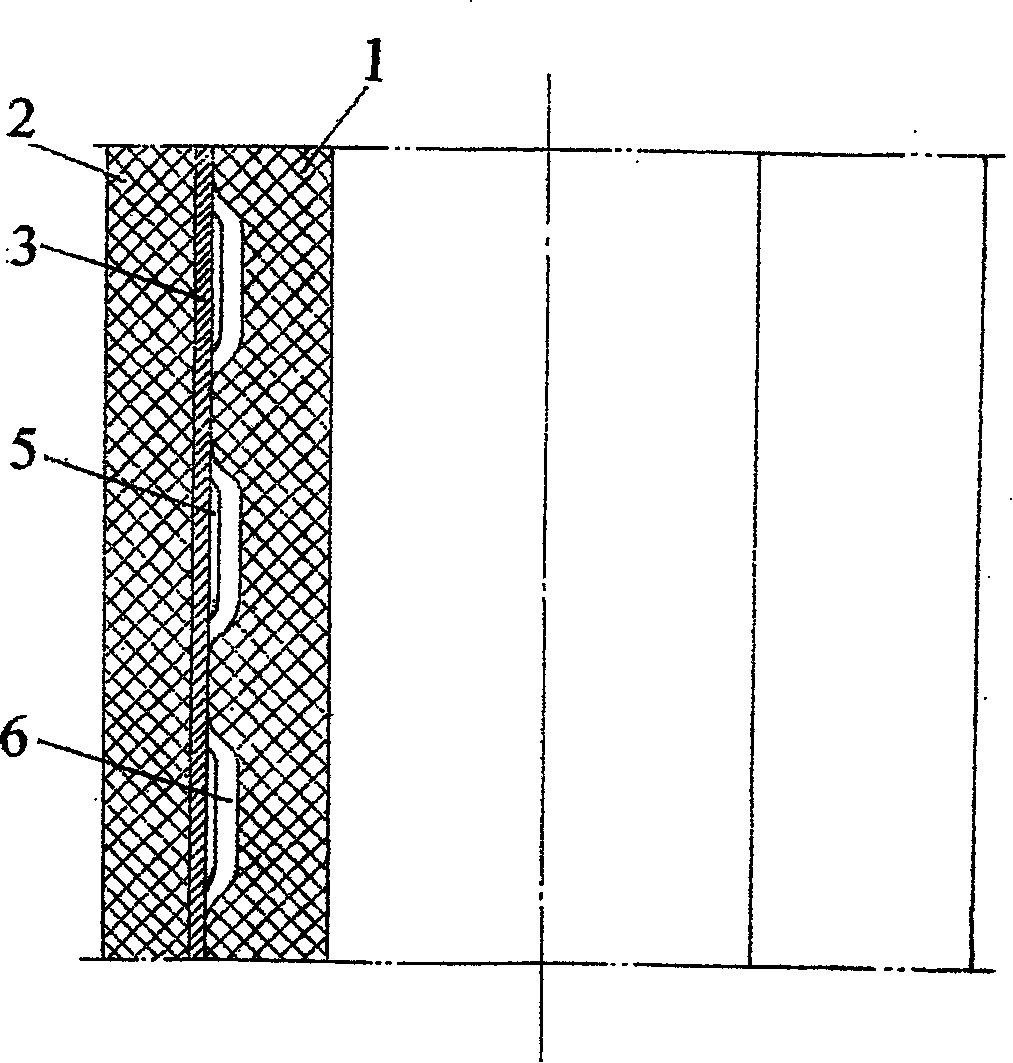

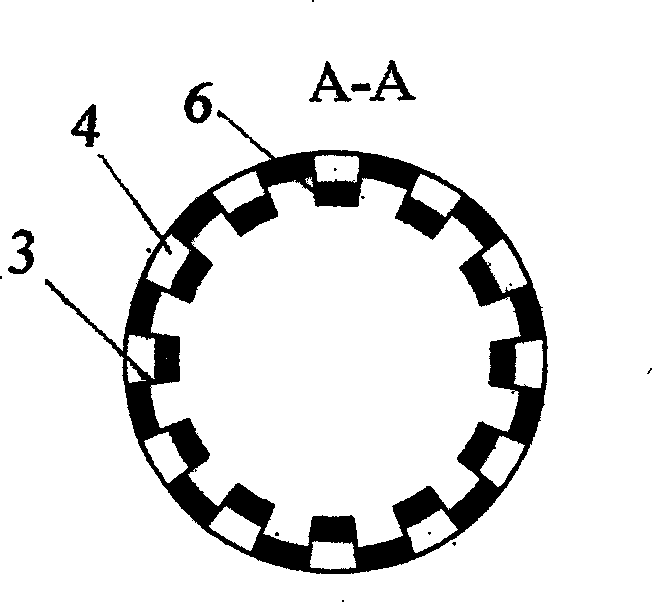

[0017] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 ,Such as figure 1 The bridge-type skeleton steel-plastic composite pipe of the present invention shown is composed of inner plastic 1 and outer plastic 2 covering the middle steel pipe 3, the outer surface of the middle steel pipe 3 is distributed with grooves 4, and the inner surface of the middle steel pipe 3 Correspondingly, there is a convex bridge 6 formed by protrusions at the bottom of the groove 4 , and the inner surface and the outer surface of the middle steel pipe 3 are connected through the slit or hole 5 in the groove 4 . The cross-section of the middle steel pipe 3 is as image 3 shown. There are at least two grooves 4 in the middle steel pipe 3, figure 1 with Figure 5 In the middle, it shows the situation that many grooves 4 are distributed, and they are distributed eve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com