Concrete building combined with heat insulating framework and its construction method

A technology of thermal insulation and combined formwork, which is applied in the direction of building construction, heat preservation, construction, etc., can solve the problems of easy damage at corners and low surface strength of wall formwork, so that it is not easy to be damaged, the construction period can be precisely controlled, and the resistance to damage can be improved. cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

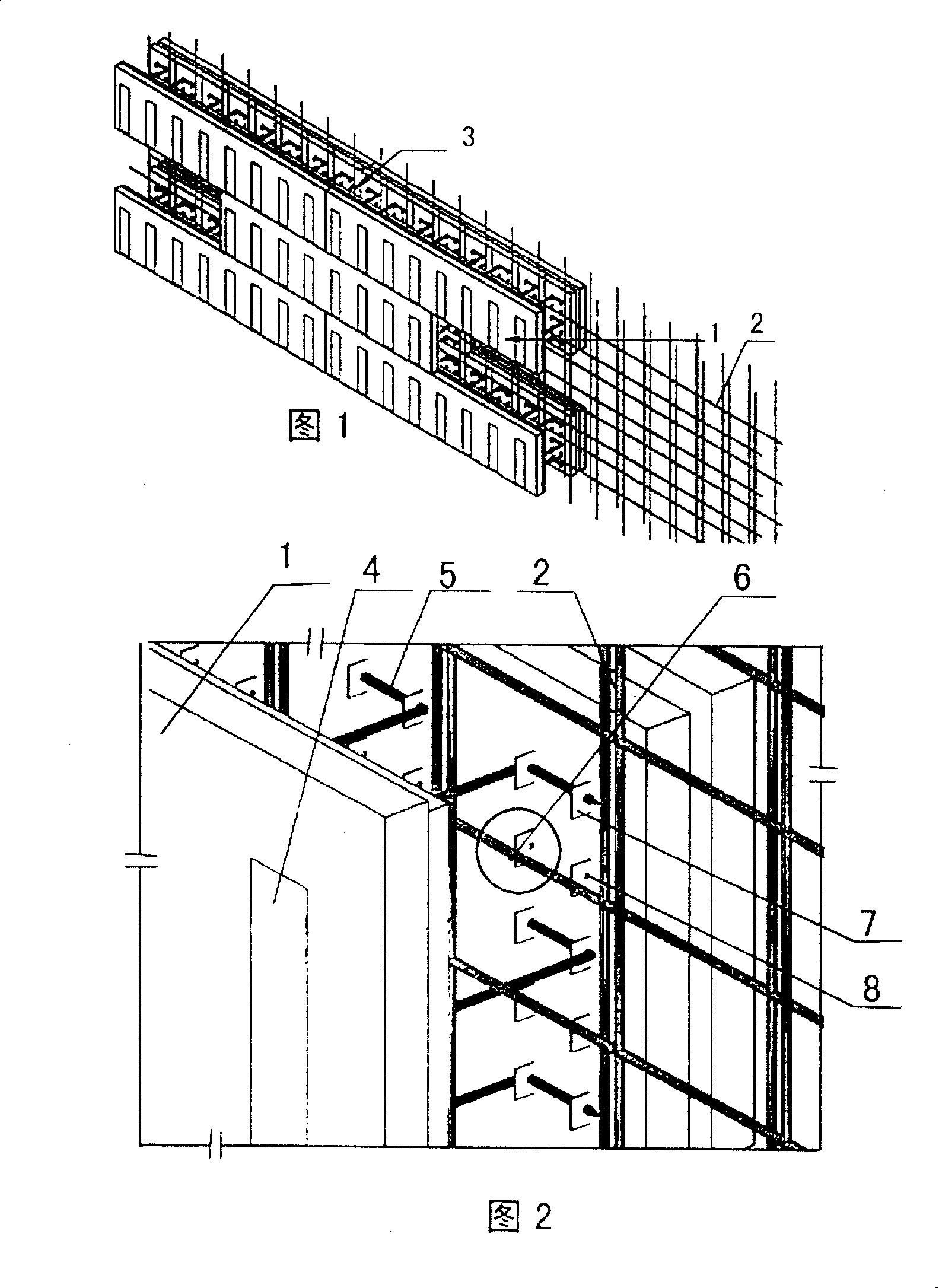

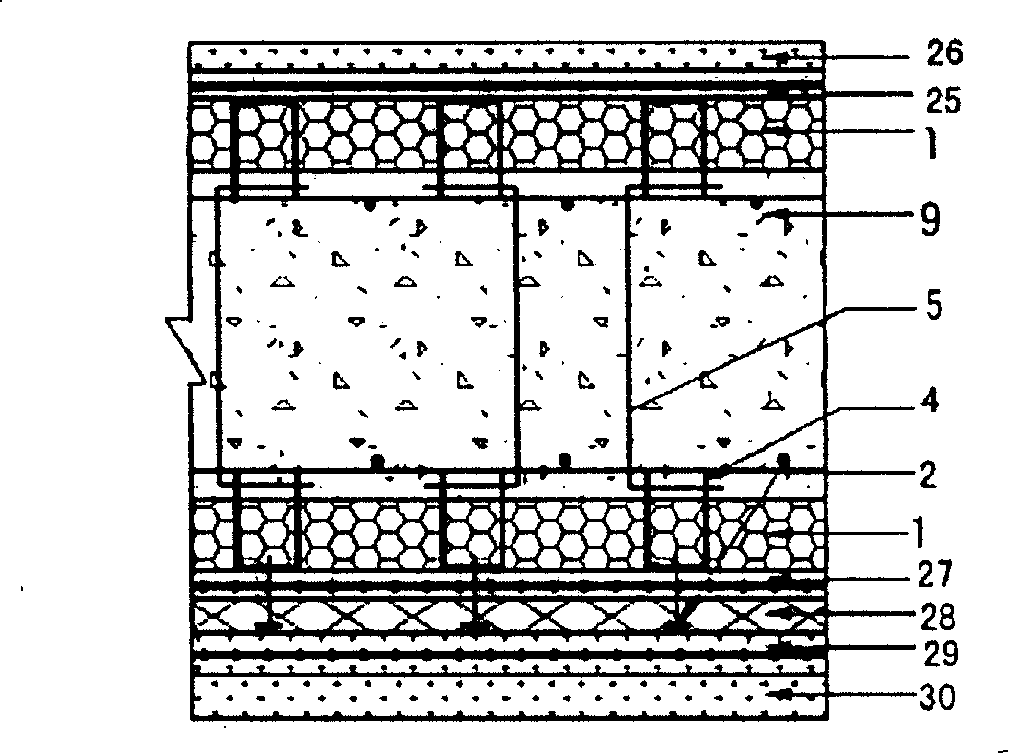

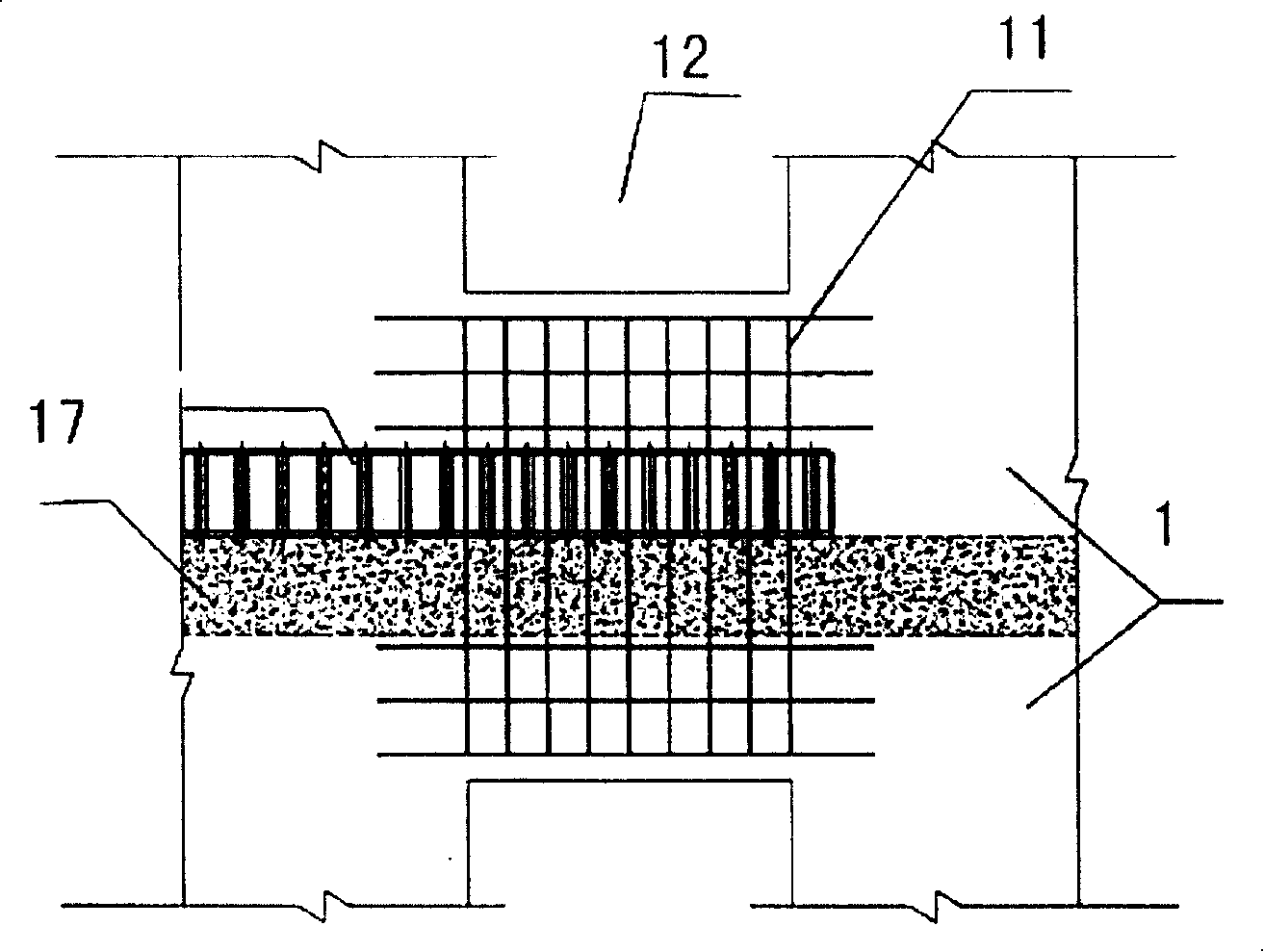

[0058] The embodiment of this kind of combined template thermal insulation concrete building is shown in Figure 1-10:

[0059] Referring to Figures 1, 2, and 3, the thermal insulation layer doubles as a wall formwork, and the concrete wall base 9 is poured in the wall formwork 1; the wall formwork is composed of two polystyrene foam side formworks arranged in parallel, and there are Built-in steel sheets 4, there are steel bar connectors 5 and steel welded mesh 2 between the built-in steel sheets, two rows of built-in steel sheets are opposite, evenly spaced, and vertically embedded in the polystyrene foam board side formwork, the edge of which is There are concave-convex teeth 7, and there are through holes 8 on the concave-convex teeth. The concave-convex teeth and the through holes are exposed on the inner surface of the polystyrene foam board side template, and the two ends of the steel bar connector pass through the through holes of the built-in steel sheets on both sides....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com