Technology of sintering sulfur aluminate cement using desulfur ash

A technology of sulphoaluminate cement and desulfurization ash, which is applied in the field of firing sulphoaluminate cement, can solve the problem that the high-sulfur and high-calcium components of desulphurization ash are difficult to use, and achieve the effect of efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

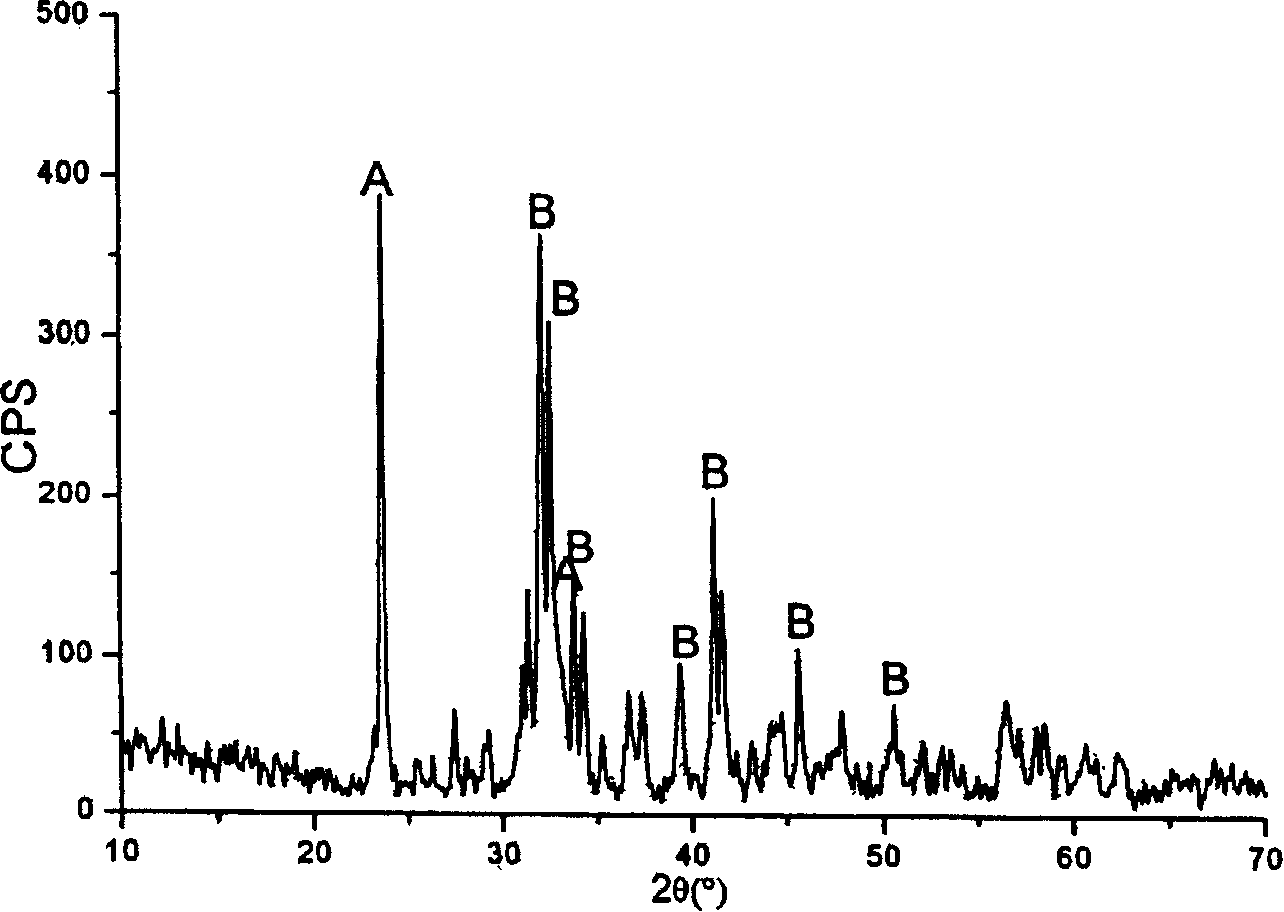

[0017] Example 1: Desulfurization ash, limestone and gypsum produced by desulfurization of coal are used as raw materials. After the mixture is ground, it is calcined in a kiln, and desulfurization ash, limestone and gypsum are used for ingredients. 36.2%, limestone 61.8%, gypsum 2%, and the main components of desulfurization ash are: SiO 2 Accounting for 43.7%, Al 2 o 3 Accounting for 24.8%, Fe 2 o 3 4.1%, CaO 11.8%, SO 3 7.5%. The calcination temperature is 1300° C., and the calcination time is 30 minutes. The obtained product has been subjected to a compressive strength test, and the compressive strengths at 3 days and 28 days are 27.6 MPa and 48.5 MPa respectively.

example 2

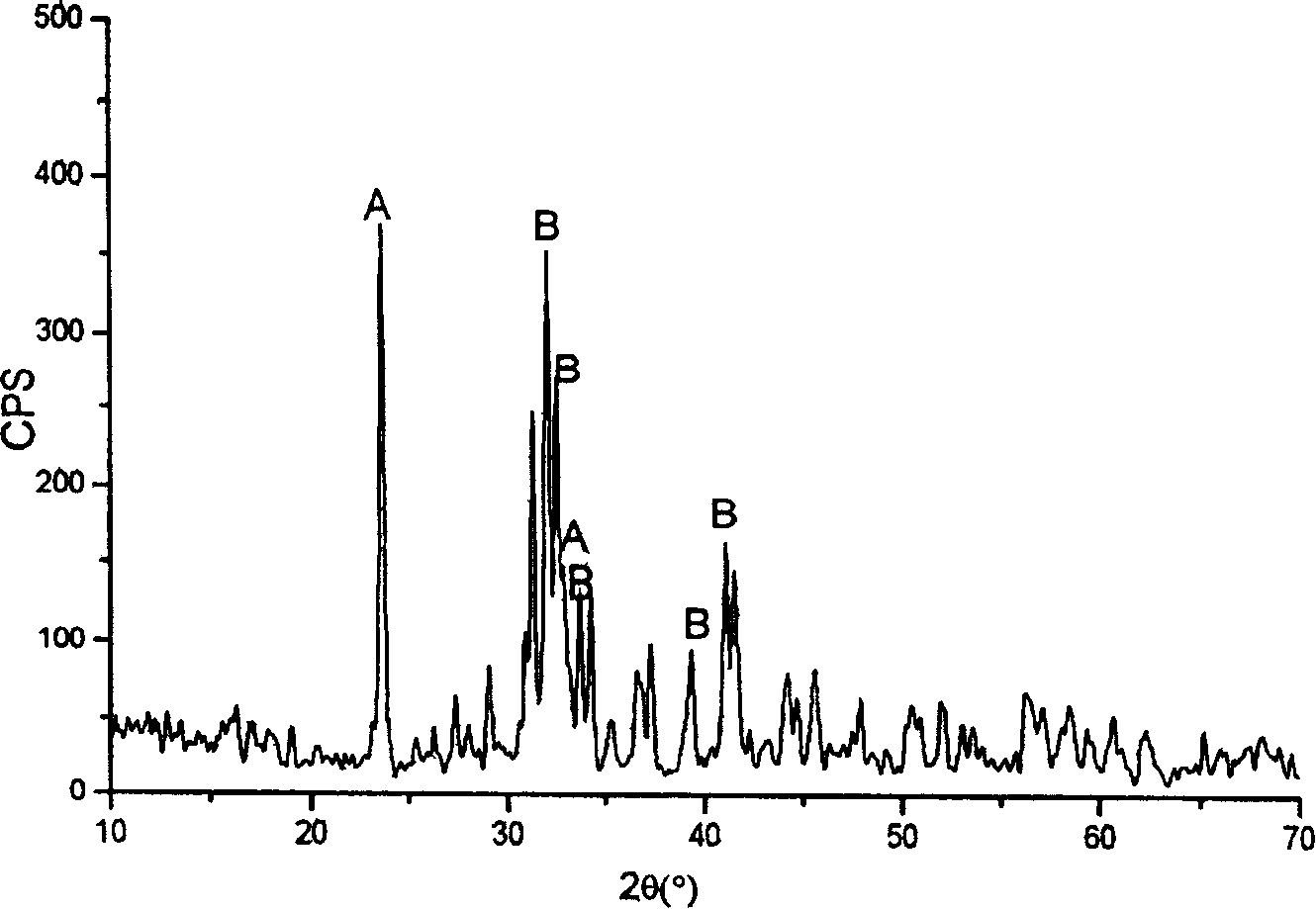

[0018] Example 2: Desulfurization ash, limestone and gypsum produced by desulfurization of coal are used as raw materials. After the mixture is ground, it is calcined in a kiln, and desulfurization ash, limestone and gypsum are used for batching. By weight percentage, desulfurization ash accounts for 34.3%, limestone 53.4%, gypsum 12.3%, and the main components of desulfurization ash are: SiO 2 Accounting for 48.7%, Al 2 o 3 Accounting for 31.8%, Fe 2 o 3 6.1%, CaO 2.8%, SO 3 1.5%. Calcination conditions are the same as the previous example. The obtained product has been subjected to a compressive strength test, and the compressive strengths at 3 days and 28 days are 25.6 MPa and 47.9 MPa respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com