Floor brush device of dust collector

A technology of vacuum cleaners and suction ports, applied in the direction of suction nozzles, etc., can solve the problems of affecting the cleaning effect and being unable to continue pumping, and achieve the effect of reducing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

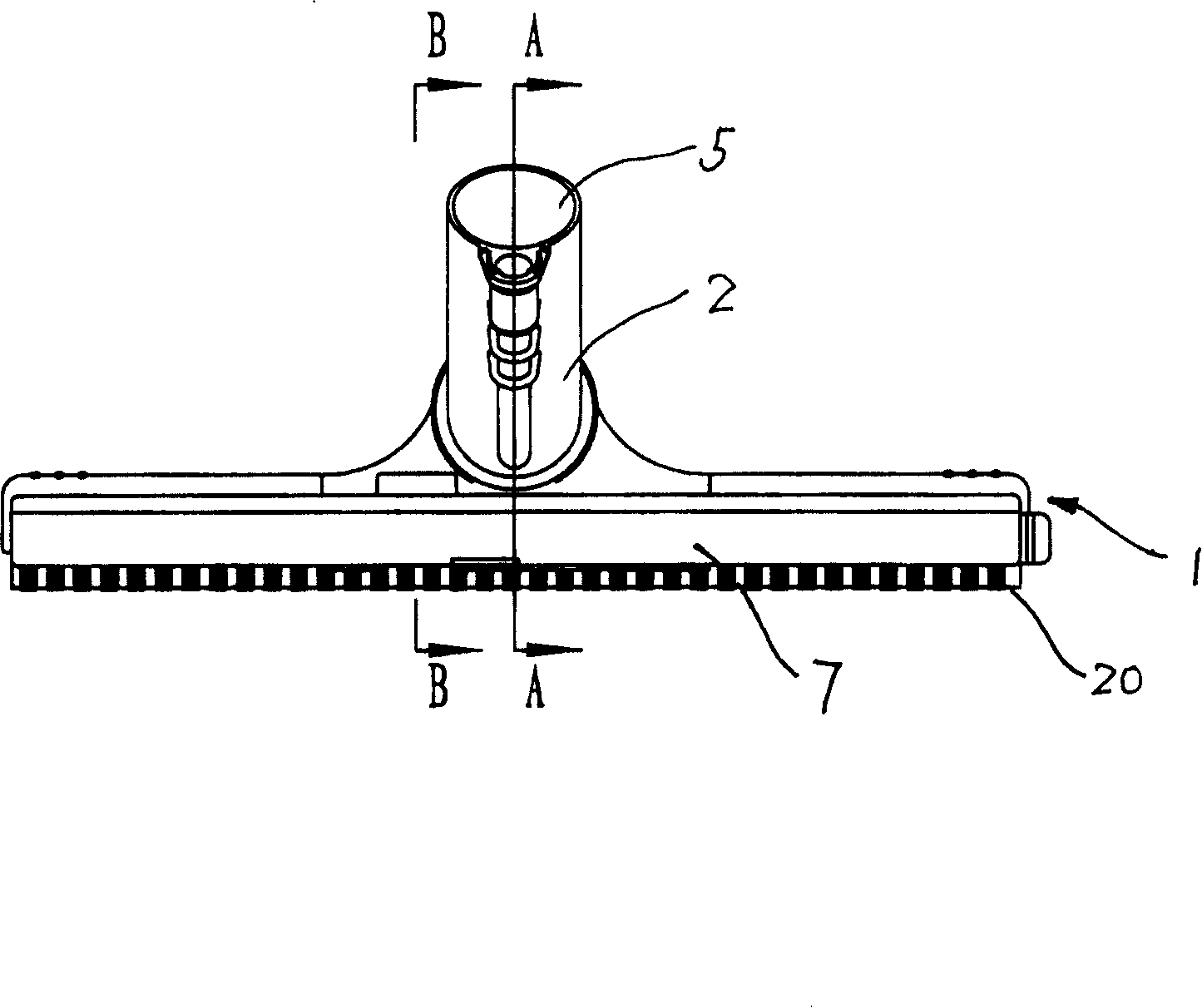

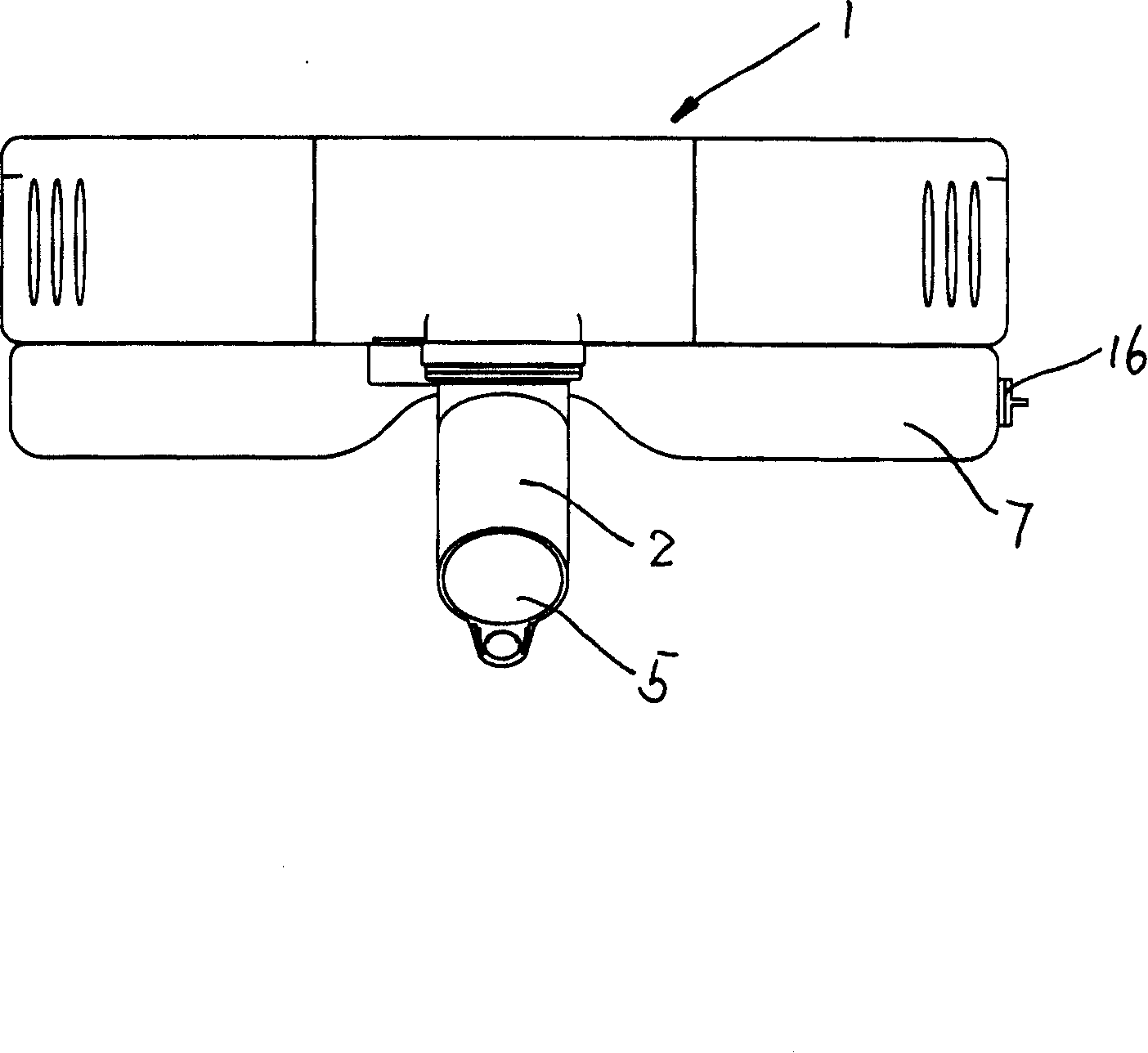

[0022] as attached figure 1 , attached figure 2 , and attached Figure 5 As shown, a floor brush device of a vacuum cleaner includes a floor brush body 1 and a pipe joint 2 arranged on the floor brush body 1 . The ground brush body 1 includes a housing 11 , a bottom plate 6 , and a brush 20 and a roller 21 arranged on the bottom plate 6 . The bottom plate 6 is provided with a suction port 3 . The floor brush body 1 is provided with a dust suction passage 4 inside, and the pipe joint 2 has a lumen 5 inside, and the dust suction port 3 communicates with the lumen 5 through the dust suction passage 4 .

[0023] The ground brush device of the vacuum cleaner also includes a water storage tank 7 . The water storage tank 7 includes an upper cover 18 and a lower box body 17, and the water storage tank 7 is formed by interlocking the upper cover 18 and the lower box body 17. A water inlet 19 is provided on the top of the water storage tank 7 , and a water discharge port 15 is pro...

Embodiment 2

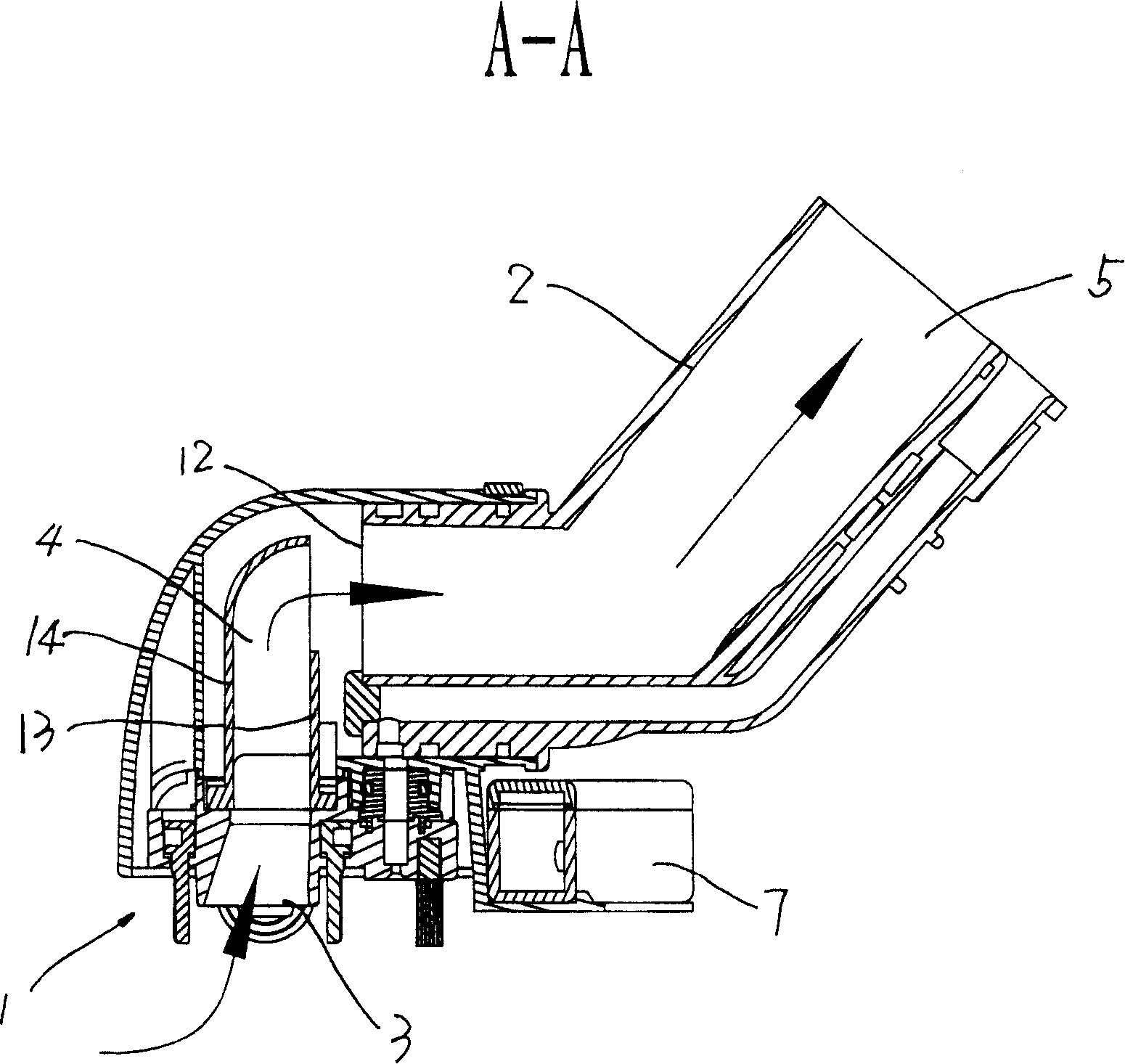

[0029] as attached image 3 As shown, in the normal working state of the vacuum cleaner, the suction airflow generated in the floor brush device of the vacuum cleaner according to the present invention flows as shown by the arrow in the figure. The liquid on the surface to be cleaned enters the suction channel 4 from the suction port 3 along with the suction gas, and enters the interior of the vacuum cleaner through the lumen 5 in the pipe joint 2 .

[0030] as attached Figure 4 And attached Figure 6 As shown, when the power of the vacuum cleaner is turned off, the suction force of the liquid-solid vacuum source in the hard tube of the vacuum cleaner (not shown in the figure) decreases to generate backflow, and the flow direction of the backflow liquid is shown in the direction of the arrow in the figure. The reflux liquid flows back down along the lumen 5 of the pipe joint 2 , is blocked by the reflux baffle 13 , and is collected by the liquid collection tray 9 , and flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com