Fan combination and fan speed-governing method

A speed regulation method and fan speed technology, applied in cooling/ventilation/heating transformation, pump control, non-variable pumps, etc., can solve the problem of noise and dust ingress reduction, board temperature changes, equipment temperature rise, etc. problem, achieve the effect of solving noise and dust-proof problems, improving service life and solving heat dissipation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0094] The first embodiment: Here, only the determination process of the four parameters is introduced, and the other processes are the same as those described above, so they will not be repeated here.

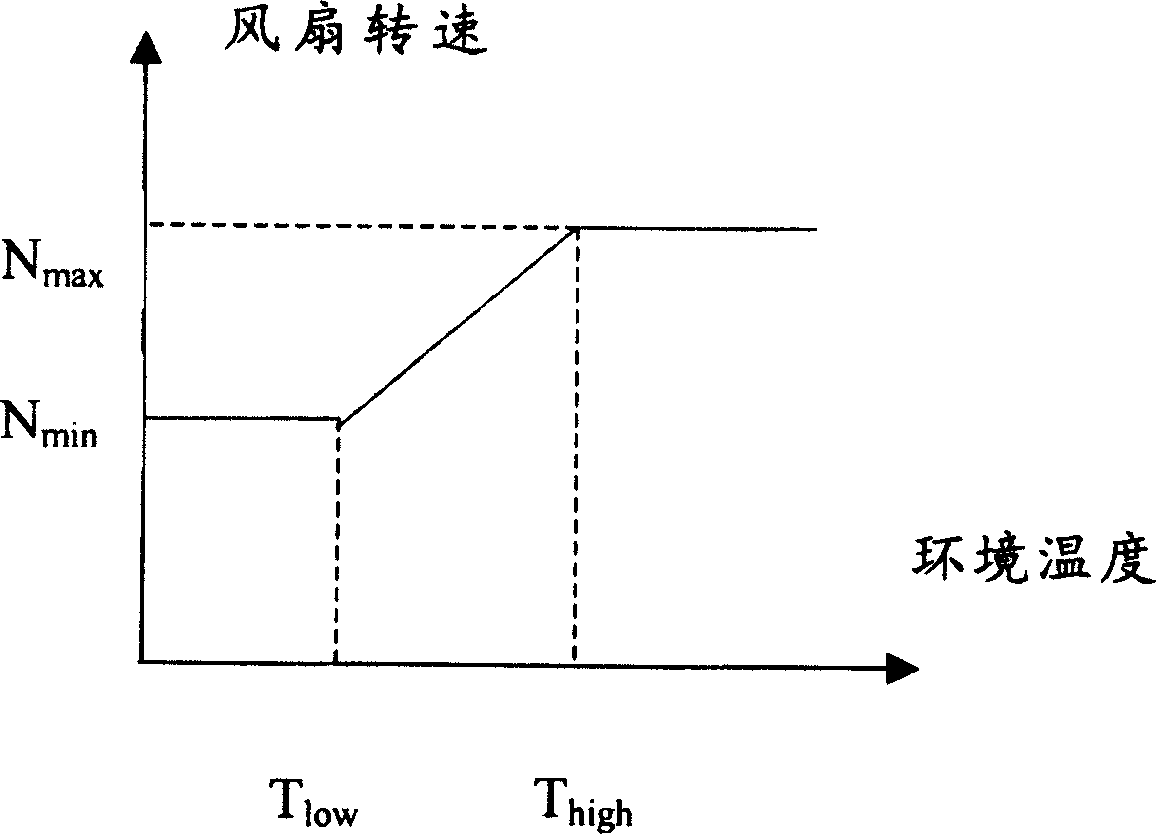

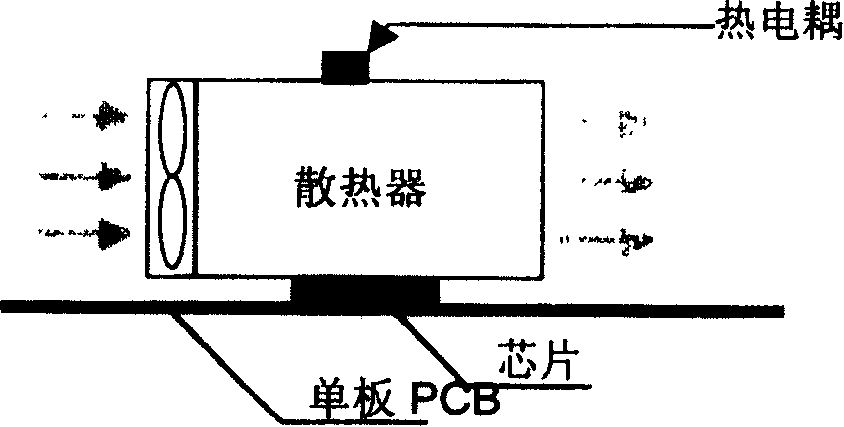

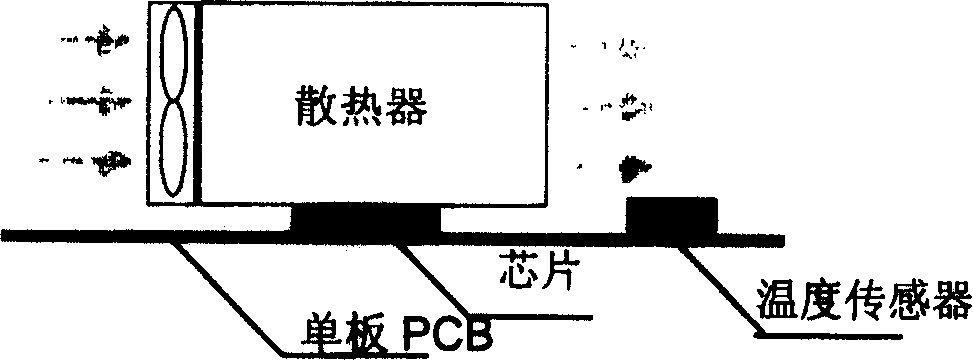

[0095] (1) Since the present invention adjusts the speed based on the actual chip temperature inside the device, once the device configuration changes or the state of business operation causes the temperature to rise, the present invention can automatically increase the speed of the fan to ensure that the heat dissipation of the system can meet the requirements of the chip. Requirements, so the speed regulation curve can be determined according to the standard configuration of the equipment and the average business traffic in the standard configuration of the single board. In addition, all the single boards can run the business normally, and the business can not be at the line speed. When determining the two variable speed control points, put the equipment into a temperature co...

no. 2 example

[0098] The second embodiment: Here, only the determination process of the four parameters is introduced, and the other processes are the same as those described above, so they will not be repeated here.

[0099] In order to prevent the heat dissipation inside the device from meeting the heat dissipation requirements in the limit state, that is, when the chip business is running at line speed and the board is fully configured, the determination of the four parameters can also be performed according to the existing fan adjustment based on the ambient temperature. speed method, in determining the T of the speed regulation curve low and T high , ensure that the system is fully configured and that all board services run at line speed. The specific steps are as follows: (1) The fan speed is controlled at N min (Generally take 50% of the rated fan speed), the equipment is fully configured, and all services are running at line speed. Put the device in the temperature control box for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com