Small power vertical axle wind-mill generator

A wind turbine, low-power technology, applied in wind turbine components, wind turbines, wind turbine combinations, etc., can solve problems such as inability to efficiently absorb wind energy, low resistance ratio between forward and reverse winds, difficult for home industry workshops, etc. The effect of long effective power generation time, small footprint and less material used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

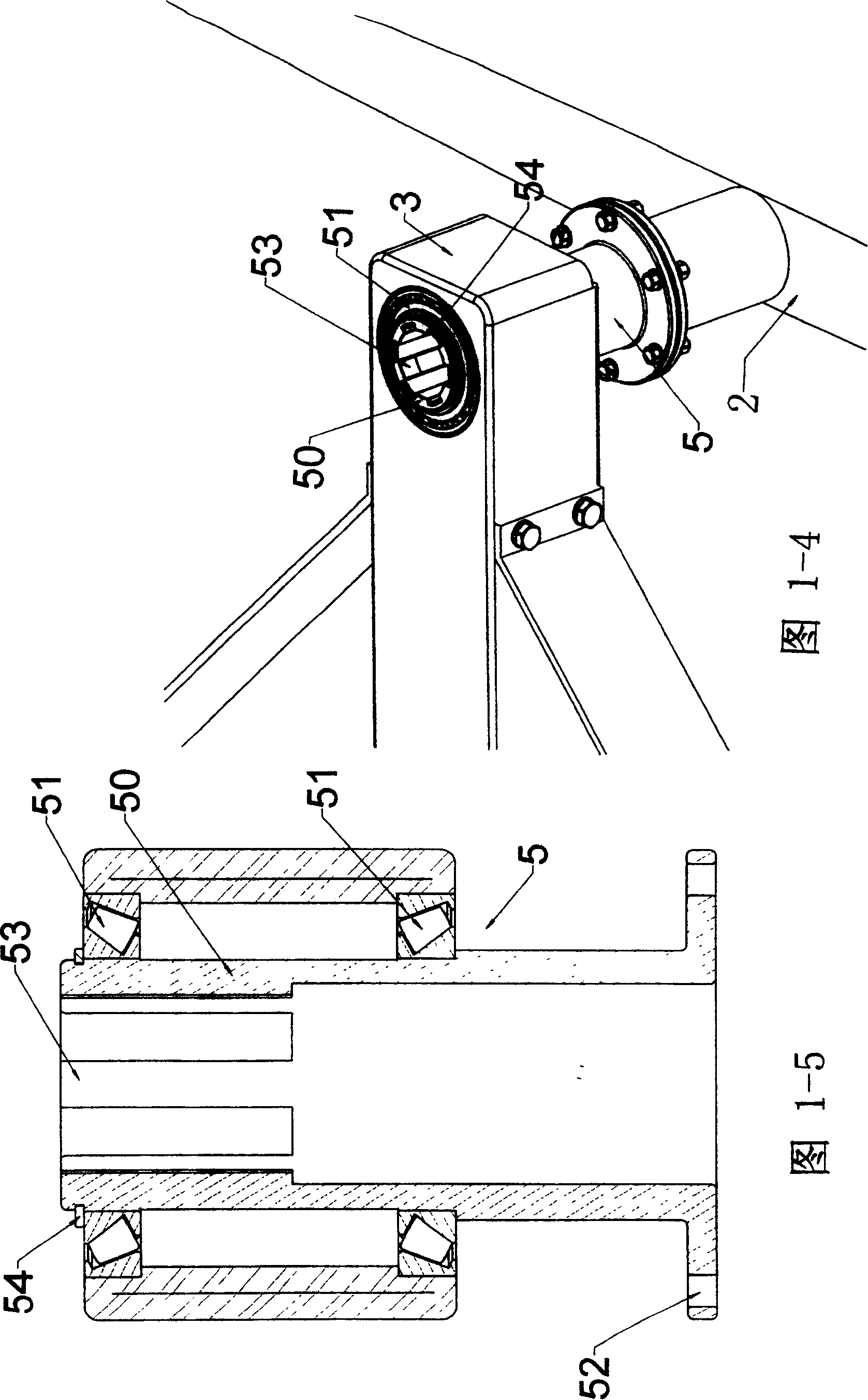

[0040] As shown in Figures 1-1, 1-2, 1-3, and 1-4, the low-power vertical axis wind power generator described in the present invention is constituted as follows: the upper and lower ends of the central column 1 are fixedly supported by the upper sail blades Disc 3 and lower sail blade support disc 4, there are 4 sail blades 2 installed between the two sail blade support discs, each sail blade 2 is rotatably mounted on the upper and lower sails through two upper and lower sail blade couplings 5 Between the leaf supporting discs 3 and 4. In this embodiment, the lower end of each sail blade 2 is connected to a blade windward angle driving mechanism 8 through a blade coupling 5; the central column 1 has two rotation support points, one is an anchor 6 at the upper end, and the other is at the upper end. The lower end is the main bearing 9. They allow the central column 1 and all components assembled on the central column 1 to rotate around the central main axis. The windward angl...

Embodiment 2

[0049]Another implementation method of the central rotation mechanism of the low-power vertical-axis wind turbine according to the present invention is shown in Fig. 4-1. Referring to Fig. 4-2, the anchor 6 is composed of a central shaft 20, a bearing assembly 21, and an anchoring disk 22, wherein a central shaft 20 is set in the center of the anchoring disk 22, and a stop 201 is provided at the lower end of the central shaft 20, through which the The central shaft 20 passes through the central column 1 and is fixed on the lower chassis rotation central shaft 904 of the main bearing 9; the upper part of the central shaft 20 is movably installed with the central column 1 through the bearing assembly 21, and the anchor plate 22 passes through the anchor ring 15 , steel cable 13 anchors. Therefore, the connection between the central shaft 20 and the lower chassis 901 of the main bearing thrust bearing is fixed and does not rotate during the operation of the wind power generator. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com