Biological template method for preparing antireflection film

An anti-reflection and thin-film technology, applied in nanostructure manufacturing, instruments, coatings, etc., can solve the problems of expensive equipment, difficulty in achieving low cost, mass production, and complexity, and achieve simple process, low cost, and enhanced transparency. The effect of passing or absorbing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

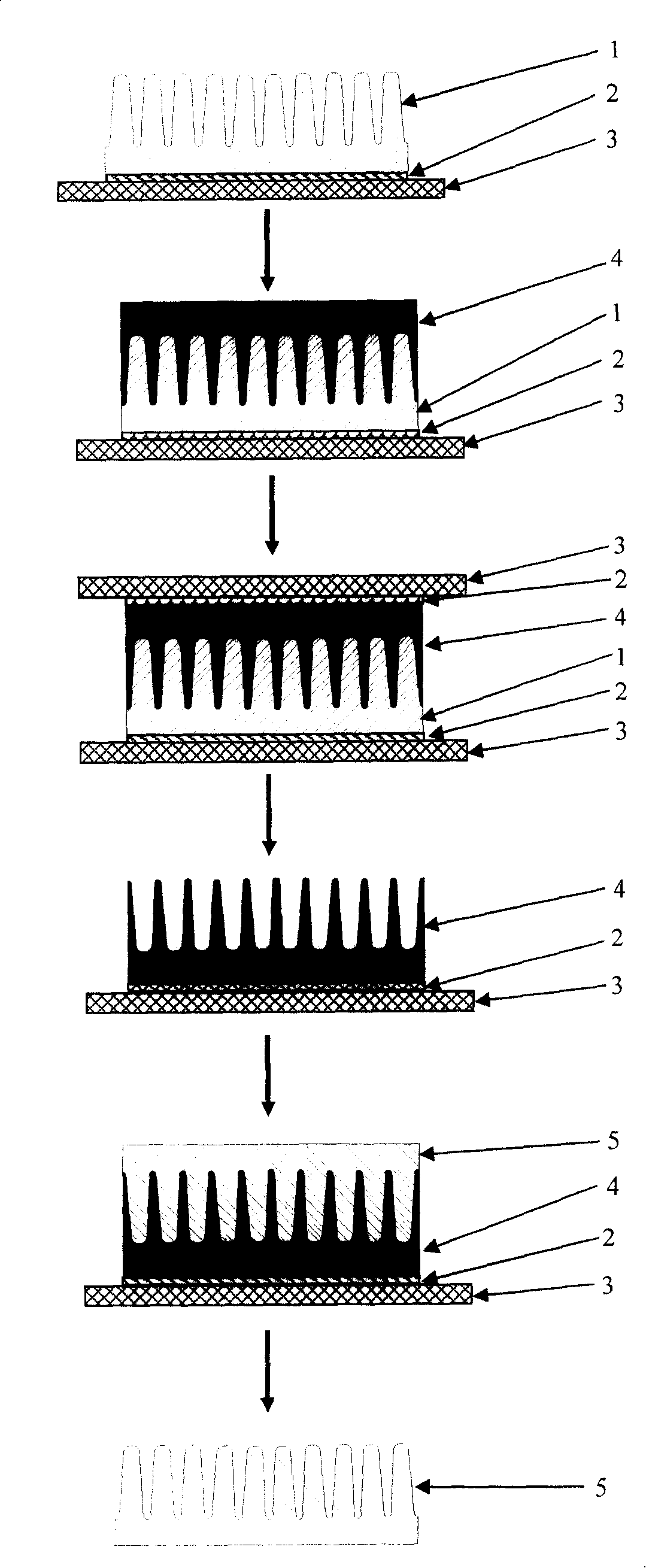

[0020] (1) Adult cicada wings were ultrasonically cleaned in acetone for 5 minutes, then ultrasonically cleaned in ultrapure water for 2 minutes, and placed in air to dry naturally.

[0021] (2) The cleaned and dried cicada wings are pasted on the surface of the silicon substrate with organic glue, and placed in a vacuum coating machine. -6 Metal Au with a thickness of 300nm was evaporated under the vacuum condition of mbar.

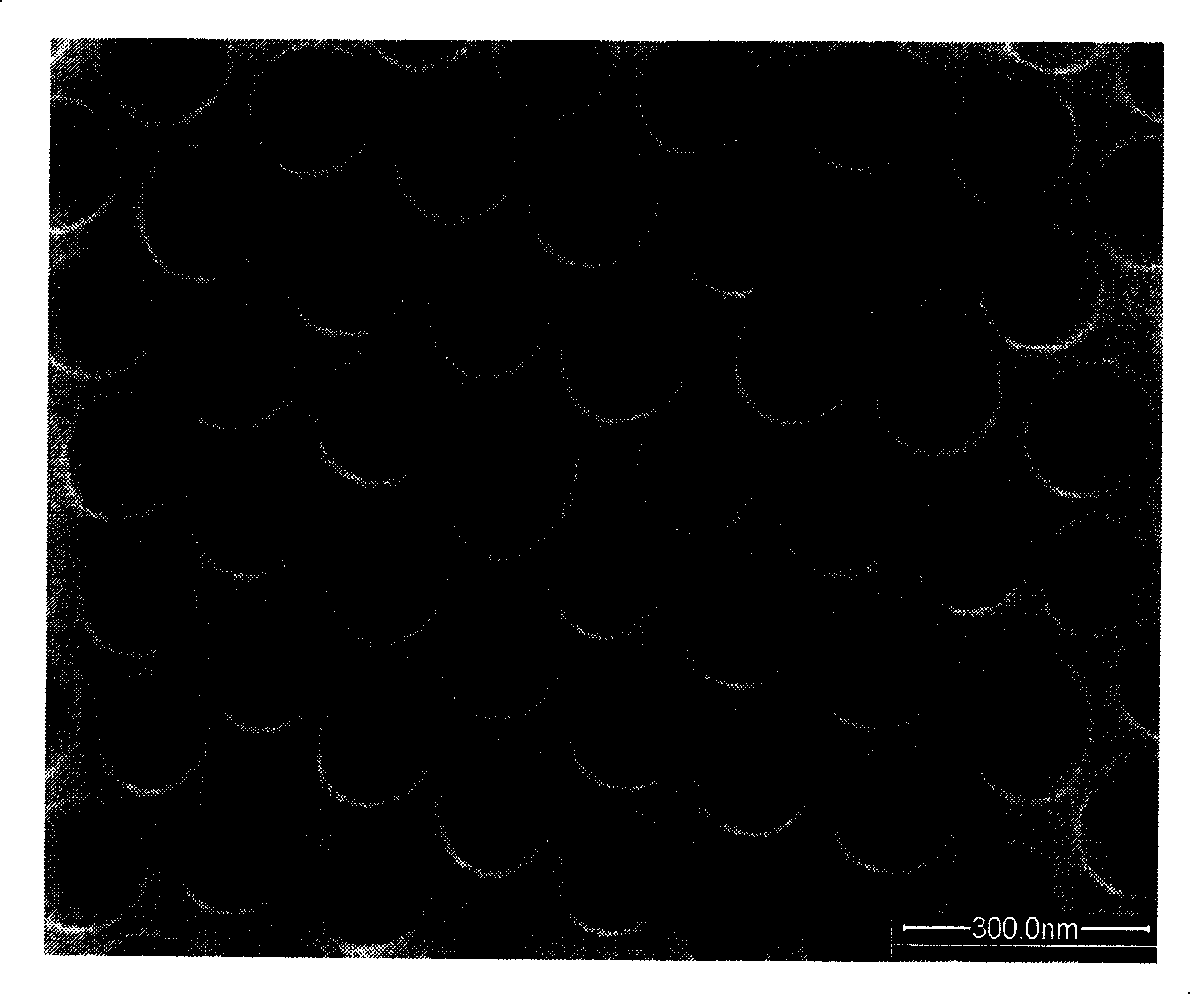

[0022] (3) Take out the evaporated metal sample from the vacuum coating machine, use EPO-TEK 377 organic glue to bond the evaporated metal Au film to another silicon substrate under the condition of curing 1hr at 150°C, and remove the Au film from The surface of the cicada wing is peeled off, and the negative structure corresponding to the surface structure of the cicada wing is obtained on the surface of the Au film (the side that is close to the cicada wing), such as image 3 shown. This metal film is used as a template for secondary replication.

[...

Embodiment 2

[0025] (1) Adult cicada wings were ultrasonically cleaned in acetone for 5 minutes, then ultrasonically cleaned in ultrapure water for 2 minutes, and placed in air to dry naturally.

[0026] (2) The cleaned and dried cicada wings are pasted on the surface of the silicon substrate with organic glue, and placed in a vacuum coating machine. -6 Metal Au with a thickness of 500nm was evaporated under the vacuum condition of mbar.

[0027] (3) Take out the vapor-deposited metal sample from the vacuum coating machine, and bond the vapor-deposited metal Au film to another silicon substrate with EPO-TEK 377 organic glue at 150°C for 1 hr. The surface of the cicada wing is peeled off, and a negative structure corresponding to the surface structure of the cicada wing is obtained on the surface of the Au film (the side closely attached to the cicada wing). This metal film is used as a template for secondary replication.

[0028] (4) the Au thin film that step (3) is obtained is placed i...

Embodiment 3

[0030] (1) Adult cicada wings were ultrasonically cleaned in acetone for 5 minutes, then ultrasonically cleaned in ultrapure water for 2 minutes, and placed in air to dry naturally.

[0031] (2) The cleaned and dried cicada wings are pasted on the surface of the silicon substrate with organic glue, and placed in a vacuum coating machine. -6 Metal Au with a thickness of 500nm was evaporated under the vacuum condition of mbar.

[0032] (3) Take out the vapor-deposited metal sample from the vacuum coating machine, and bond the vapor-deposited metal Au film to another silicon substrate with EPO-TEK 377 organic glue at 150°C for 1 hr. The surface of the cicada wing is peeled off, and a negative structure corresponding to the surface structure of the cicada wing is obtained on the surface of the Au film (the side closely attached to the cicada wing). This metal film is used as a template for secondary replication.

[0033] (4) the Au thin film that step (3) is obtained is placed i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com