High rate lithium secondary battery negative electrode material based on second phase compounding and preparation method thereof

A lithium secondary battery and negative electrode material technology, applied in the field of electrochemical power sources, to achieve the effect of simple and easy preparation process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

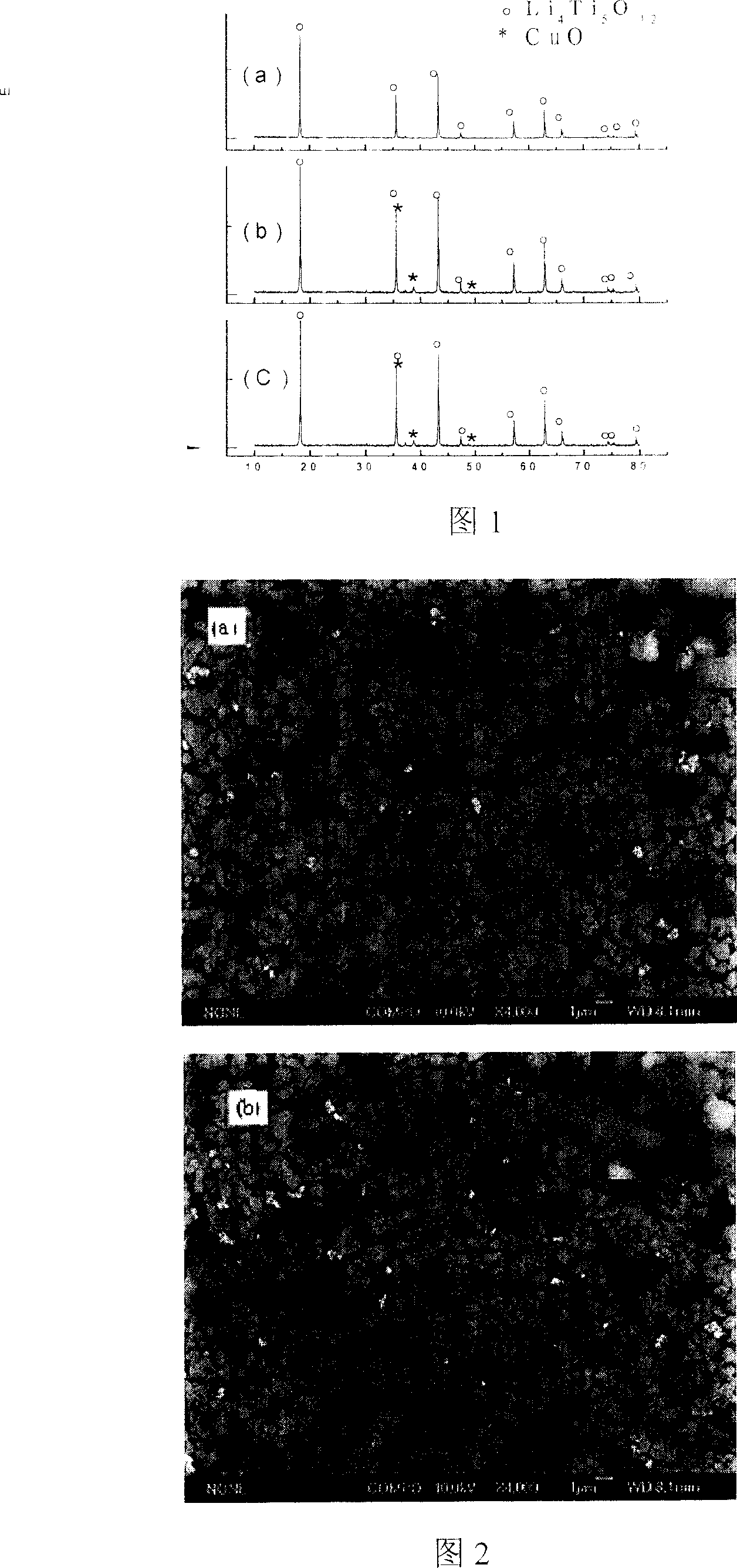

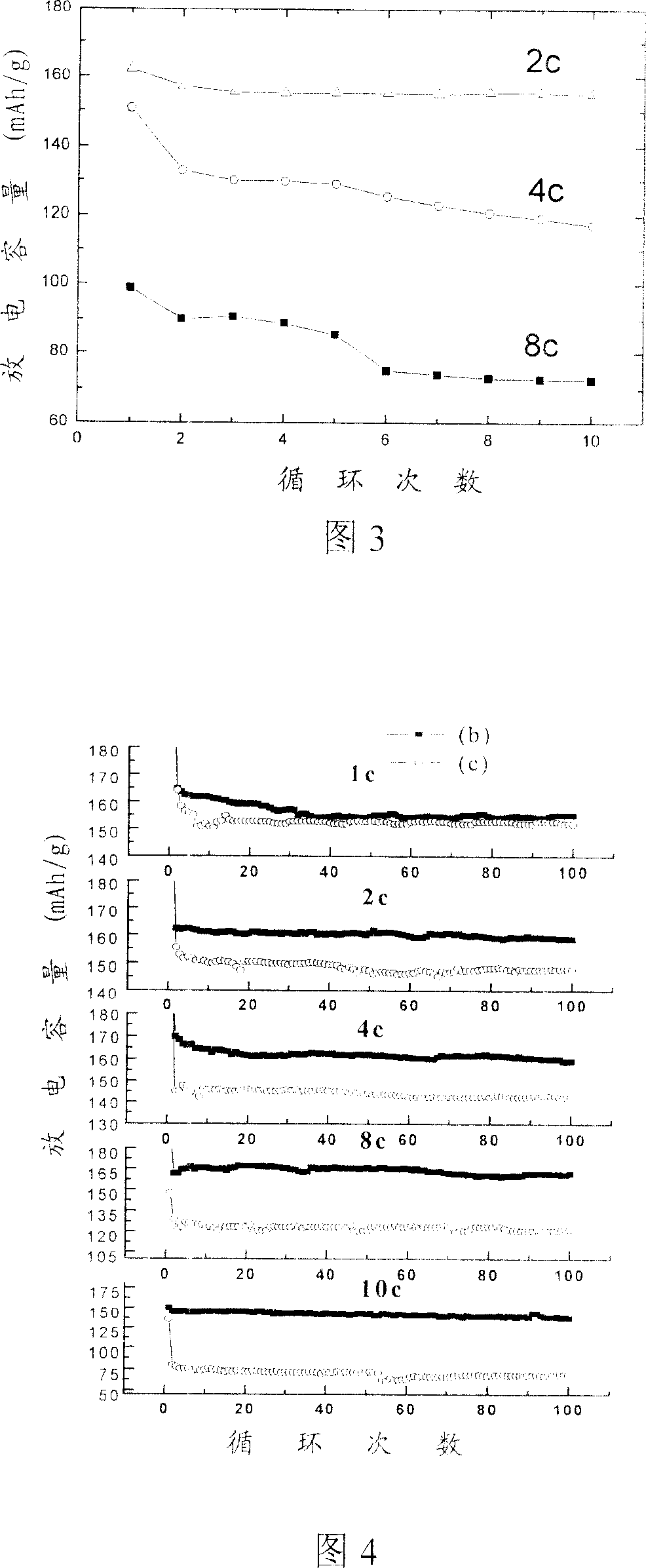

[0015] Example 2 Li 4 Ti 5 o 12 materials and Cu(NO 3 ) 2 ·3H 2 O was mixed with alcohol at a molar ratio of 7:3, ball milled for 4 hours, dried at 80°C, then calcined in a reducing atmosphere at 500°C for 2 hours, and naturally cooled to room temperature to obtain 94wt% Li 4 Ti 5 o 12 / 6wt%Cu xO composite powder. SEM is shown in Figure 2(b). The preparation method of the battery is the same as in Example 1, and the charge and discharge test is carried out. The first discharge capacity of the composite material synthesized under the reducing atmosphere between 2.3-0.5V at 2C and 8C rates is 189.8 and192.6mAh / g, the matrix compound Li prepared under the same conditions 4 Ti 5 o 12 The first discharge capacity of the first discharge capacity is 162.2 and 98.9mAh / g, containing the second phase metal copper and its oxide Cu x The initial discharge capacities of the composites with O are 14.5% and 48.7% higher, respectively. The 10th discharge capacity of the composite...

Embodiment 3

[0016] Example 3 Li 4 Ti 5 o 12 material and CuCO 3 Using water as the medium at a molar ratio of 7:5, wet mixing by ball milling for 2 hours, drying at close to 100°C, calcining in a reducing atmosphere at 550°C for 1.5 hours, and naturally cooling to room temperature to obtain 89wt% Li 4 Ti 5 o 12 / 11wt%Cu x O composite powder. The preparation method of the battery is the same as in Example 1, and the charge and discharge test is carried out. The first discharge capacity between 2.3-0.5V under the rate of 2C and 8C is 186.8and195.2mAh / g respectively, and the matrix compound Li 4 Ti 5 o 12 The first discharge capacity of the first discharge capacity is 162.2 and 98.9mAh / g, containing the second phase metal copper and its oxide Cu x The initial discharge capacities of the composites with O are 15.2% and 97.4% higher, respectively. The 10th discharge capacity of the composite material is 164.1 and 166.9mAh / g at 2C and 8C, respectively, and the matrix material is 155 a...

Embodiment 4

[0017] Example 4 Li 4 Ti 5 o 12 materials and CuC 2 o 4 1 / 2H 2 O was mixed by ball milling at a molar ratio of 7:6 for 2 hours, then calcined in a reducing atmosphere at 550 °C for 1.5 hours, and naturally cooled to room temperature to obtain 87 wt% Li 4 Ti 5 o 12 / 13wt%Cu x O composite powder. The preparation method of the battery is the same as in Example 1, and the charge and discharge test is carried out. The first discharge capacity between 2.3-0.5V under the rate of 2C and 8C is 193.8and195.2mAh / g respectively, and the matrix compound Li 4 Ti 5 o 12 The discharge capacity of the first discharge was 162.2 and 98.9mAh / g respectively, the discharge capacity of the 10th discharge was 165.1 and 167.6mAh / g for the composite material 2C and 8C respectively, and 155 and 72.5mAh / g for the matrix material. The reversible cycle capacity and stability of the composites synthesized under reducing atmosphere at various rates, especially at high rates, are significantly impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com