Method for producing zinc bismuth multicomponent alloy used for hot dip galvanizing of steel and iron members

A technology for multi-component alloys and steel components is applied in the production field of zinc-bismuth multi-component alloys used for hot-dip galvanizing of steel components, and achieves the effects of high degree of alloying, avoidance of burning damage, and clean and environmentally friendly production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

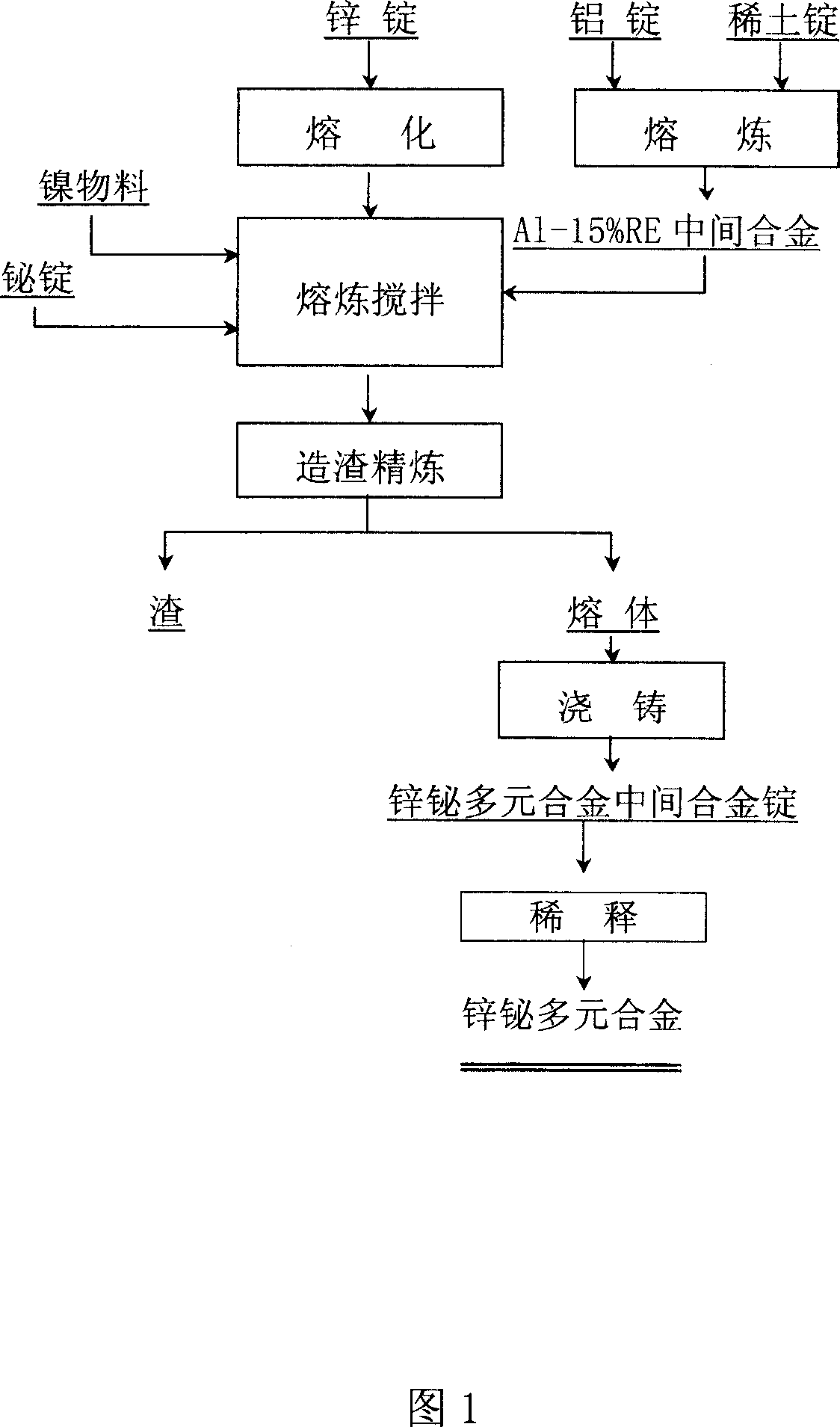

[0018] A kind of production method of zinc-bismuth multi-element alloy, its production steps are:

[0019] Step 1: Add 85% (wt) solid aluminum and 15% (wt) solid rare earth metal RE into an induction furnace directly heated by an electric field and use a zinc block as a core, heat up to a melting temperature of 750°C, and keep warm for 30 Minutes, while stirring for 8 minutes, the preparation of Al-15% rare earth metal RE master alloy;

[0020] Step 2: When 90% (wt) of the zinc ingot is melted to a temperature of 650°C in the smelting equipment, 3% (wt) of the Al-15% rare earth metal RE master alloy obtained in step 1 is added for neutralization, and then added 2.0% (wt) pure nickel material and 5% (wt) bismuth ingot, smelting for 12 minutes;

[0021] Step 3: adding refining agent to the material obtained in step 2 at 600° C. according to a conventional method, making slag and refining, removing the slag and casting it into a zinc-bismuth multi-element alloy master alloy ingo...

Embodiment 2

[0024] A kind of production method of zinc-bismuth multi-element alloy, the produced zinc-bismuth multi-element alloy is composed of its production steps as follows:

[0025] Step 1: Add 85% (wt) solid aluminum and 15% (wt) solid rare earth metal RE into a coreless induction furnace with alternating electric and magnetic fields, heat up to a melting temperature of 850°C, and keep it warm for 30 minutes. Stir for 20 minutes to prepare A1-1 5% rare earth metal RE master alloy;

[0026] Step 2: When 96% (wt) of the zinc ingot is melted to a temperature of 550°C in the smelting equipment, 2% (wt) of the Al-15% rare earth metal RE master alloy obtained in step 1 is added for neutralization, and then added 2% (wt) bismuth ingot, smelting for 20 minutes;

[0027] Step 3: adding refining agent to the material obtained in step 2 at 700° C. according to a conventional method, making slag and refining, removing the slag and casting it into a zinc-bismuth multi-element alloy master alloy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com