Coagulatory settle treatment method for rainy day overflow sewage

A technology of coagulation sedimentation and treatment method, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc. It can solve the problems of affecting the effect of sedimentation treatment, failure to react in the tank, and emission of odor, so as to save energy consumption of mechanical stirring and simplify elevation layout , The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

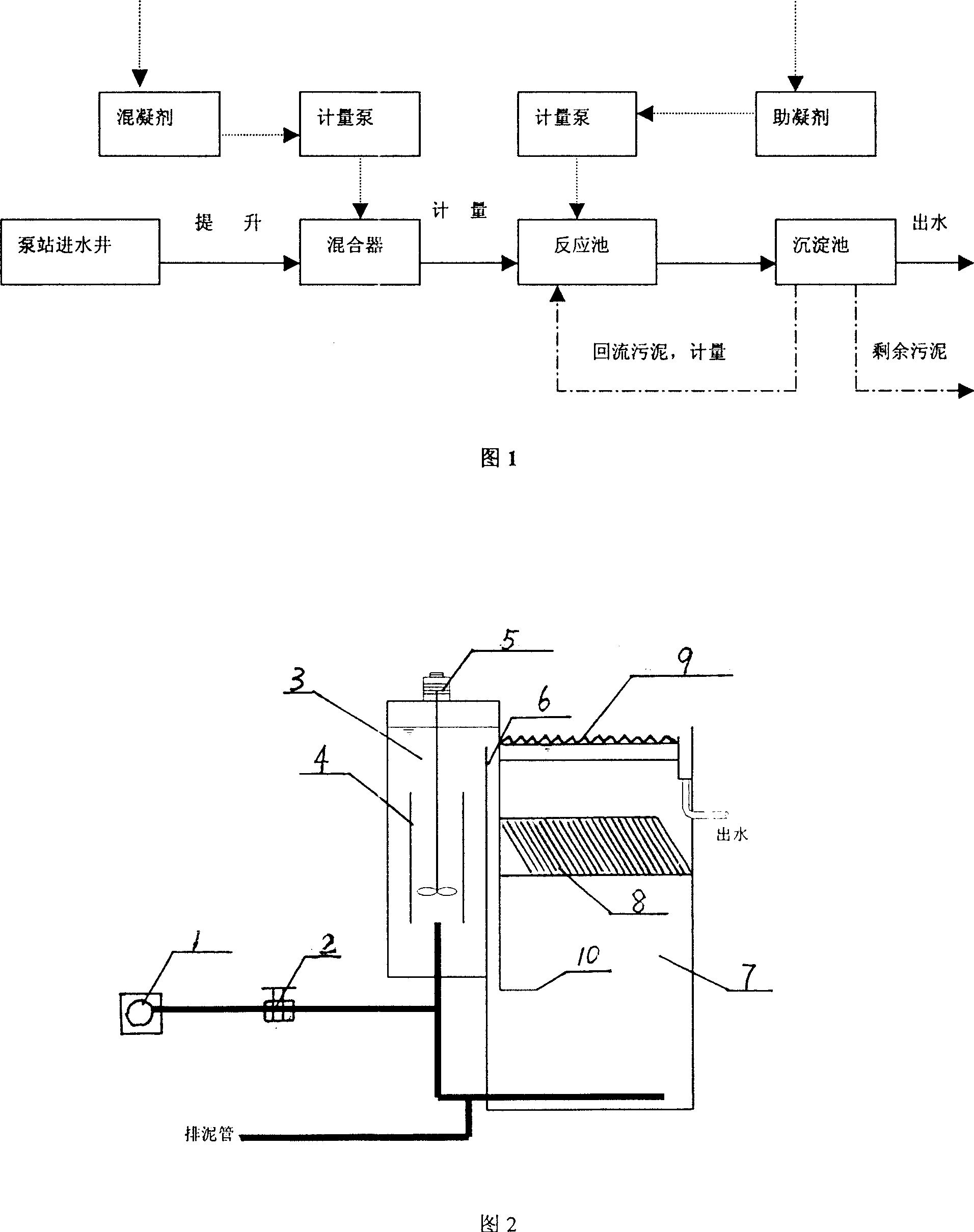

[0035] Example 1: Treatment of confluent sewage from moderate to heavy rainfall

[0036] During the rainy season in Shanghai, the rainfall intensity is generally low and the duration is relatively long. During a period of rainfall, the surface pollutants are washed into the confluence pipeline for a relatively long time, so the concentration of sewage SS and COD in the confluence pipeline is not very high, which is similar to that of drought Compared with sewage, SS has been greatly improved, COD has been reduced, and TP has not changed much.

[0037] Specific steps are as follows:

[0038] (1) Using the method of dosing before the pump, the sewage is pumped into the static mixer and fully mixed with the coagulant PAC pumped in at the same time. The mixing time is 7.5 seconds, the measured hydraulic resistance loss is 4700Pa, and the velocity gradient is 7901 / s. , PAC is 8~10mg / l, PAM is 0.8~1.0mg / l;

[0039] (2) The mixed sewage enters the reaction tank through the rotamete...

Embodiment 2

[0043] Example 2: Treatment of high-intensity rainfall primary rainwater

[0044] For the initial rainfall of heavy rainfall, the water quality changes greatly, and the water quality indicators such as SS and COD rise rapidly in a short period of time.

[0045] Specific steps are as follows:

[0046] (1) Use a metering pump to add the static mixer coagulant PAFC at the inlet of the static mixer, the mixing time is 4 seconds, the measured hydraulic resistance loss is 10600Pa, and the velocity gradient value is 14501 / s, among which PAFC is 10 ~ 15mg / l, PAM is 1.0~1.2mg / l;

[0047] (2) The mixed sewage enters the reaction tank through the rotameter, and reacts with the coagulant PAM in the reaction tank by stirring, and the reaction time is 3.3 minutes; the stirring of the stirring paddle in the reaction tank makes the inside and outside of the guide tube form an up and down flow , to create hydraulic conditions for the growth of flocs to achieve the purpose of coagulation, th...

Embodiment 3

[0052] For low-temperature mixed overflow sewage, the water quality indicators such as SS and COD are relatively high.

[0053] Specific steps are as follows:

[0054] (1) The way of dosing before the pump is adopted. The sewage is pumped into the static mixer and fully mixed with the coagulant PFS pumped in at the same time. The mixing time is 10 seconds, the measured hydraulic resistance loss is 8000Pa, and the velocity gradient value is 10001 / s. Among them, PFS is 10-15mg / l, and PAM is 1.2mg / l;

[0055] (2) The mixed sewage enters the reaction tank through the rotameter, and reacts with the coagulant PAM in the reaction tank by stirring, and the reaction time is 10 minutes; the stirring of the stirring paddle in the reaction tank makes the inside and outside of the guide tube form an up and down flow , to create hydraulic conditions for the growth of flocs to achieve the purpose of coagulation, the stirring speed is 100 rpm;

[0056] (3) The water flows over the overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com