Germanium-silicon schottky diode and its production method

A Schottky diode, germanium-silicon technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of device isolation and integration process limitations, and achieve the goal of reducing interface density, improving integration, and simplifying processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is further described below in conjunction with specific examples.

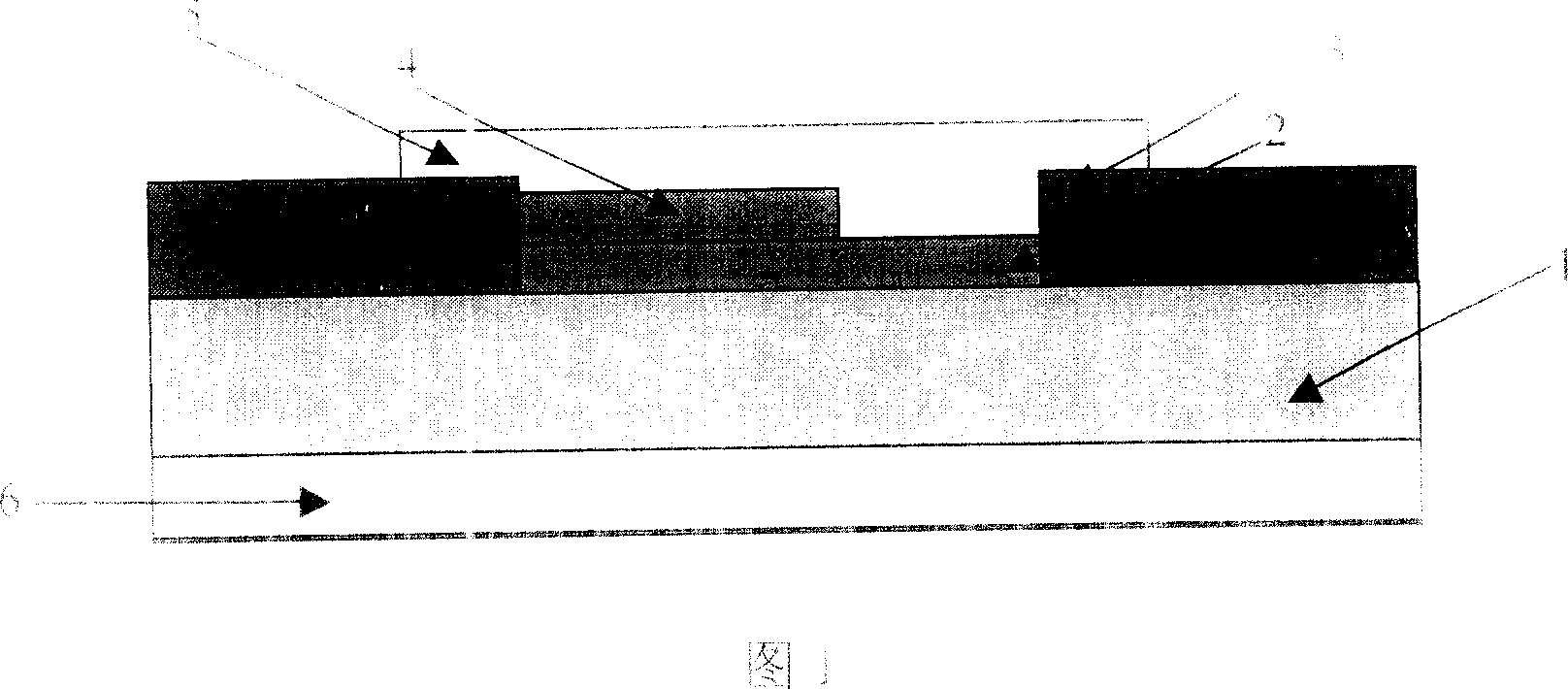

[0019] Referring to Fig. 1, the SiGe Schottky diode of the present invention comprises a silicon substrate 1, a silicon germanium layer 2, a silicon nitride layer 3 with a window, a nickel-silicon compound layer 4, an aluminum electrode 5 and an ohmic contact electrode 6, the ohmic The contact electrode 6, the silicon substrate 1 and the silicon nitride layer 3 with a window are successively stacked from bottom to top, and the silicon germanium layer 2 and the nickel-silicon compound layer 4 are in the window of the silicon nitride layer 3, wherein the nickel-silicon compound layer Layer 4 is on top of silicon germanium layer 2, covering the aluminum electrodes in contact with the nickel silicon compound layer over the windows of the silicon nitride layer.

[0020] The manufacturing method of silicon germanium Schottky diode, the steps are as follows:

[0021] 1) Clean the N-type ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com