Method and device for feeding polymerization liquid

A liquid and liquid pipeline technology, applied in the field of transporting polymerizable liquids, can solve the problems of reducing the working failure, damage and leakage of extrusion sliding parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

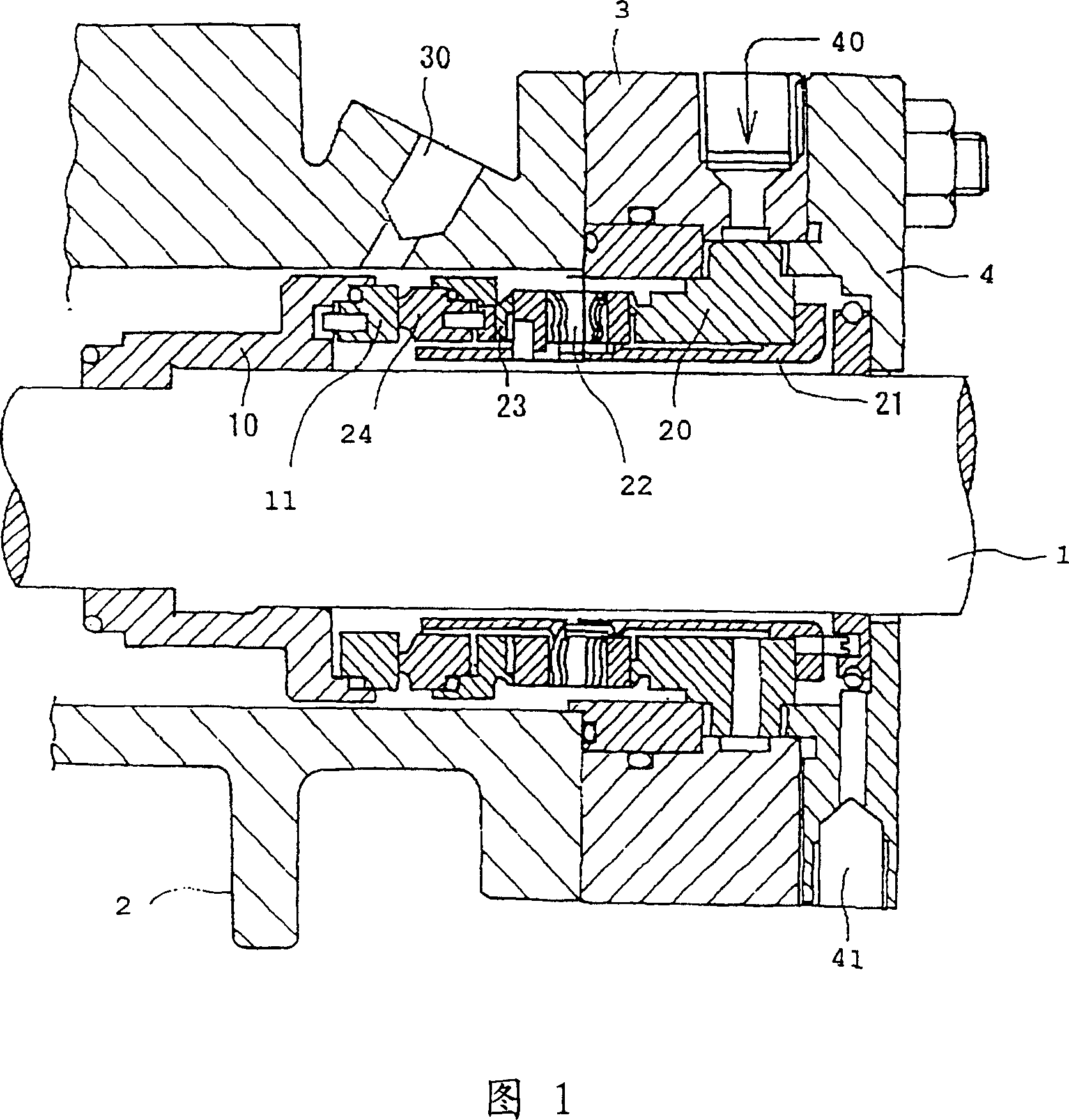

[0037] A mechanical seal pump of the external flushing type shown in Figure 1 was used as the pump for removing bottoms from the column containing a large amount of acrylic acid heavy condensate. The feed liquid of the column is used as the external flushing liquid. In the flushing line, the 100-mesh filter is arranged in parallel, and U-shaped pressure gauges are arranged on the upstream and downstream sides of the filter, so that when the pressure difference in the filter part increases, the line can be switched. Steam quenching was also performed.

[0038] As a result, the fluid can be transferred for 1 year without causing any problems.

[0039] Next, the mechanical seal shown in Fig. 1 is explained.

[0040] The rotary shaft 1 is arranged so as to pass through the housing 2 , the seal cover 3 and the end cover 4 . The rotary-side sealing surface 11 has been connected to the rotary shaft 1 via the rotary-side sleeve 10 . The bellows 22 and the face holder 23 have been ...

Embodiment 2

[0042] A self-flushing type mechanical seal pump was used as the pump for withdrawing the distillate from the column containing a large amount of acrylic acid. The pump was operated while the polymerization inhibitor was added to the rinse liquid in an amount corresponding to 100 ppm. As a result, the liquid can be transferred for 1 year without causing any problems.

Embodiment 3

[0046] A self-flushing type (liquid temperature: 70° C.) was used as a pump for discharging the residue from the acrylic acid purification tower. A heat exchanger for cooling is arranged for flushing liquid lines. Run the pump while reducing the temperature of the liquid to 25-30°C. As a result, the liquid can be transferred for 1 year without causing any problems.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com