Coaxial composite continuous nano/micron fiber and its preparation method

A technology of micron fibers and fibers, which is applied in the field of coaxial composite continuous nano/micron fibers and their preparation, can solve problems such as not found, and achieve the effects of easy functionalization, low equipment cost, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

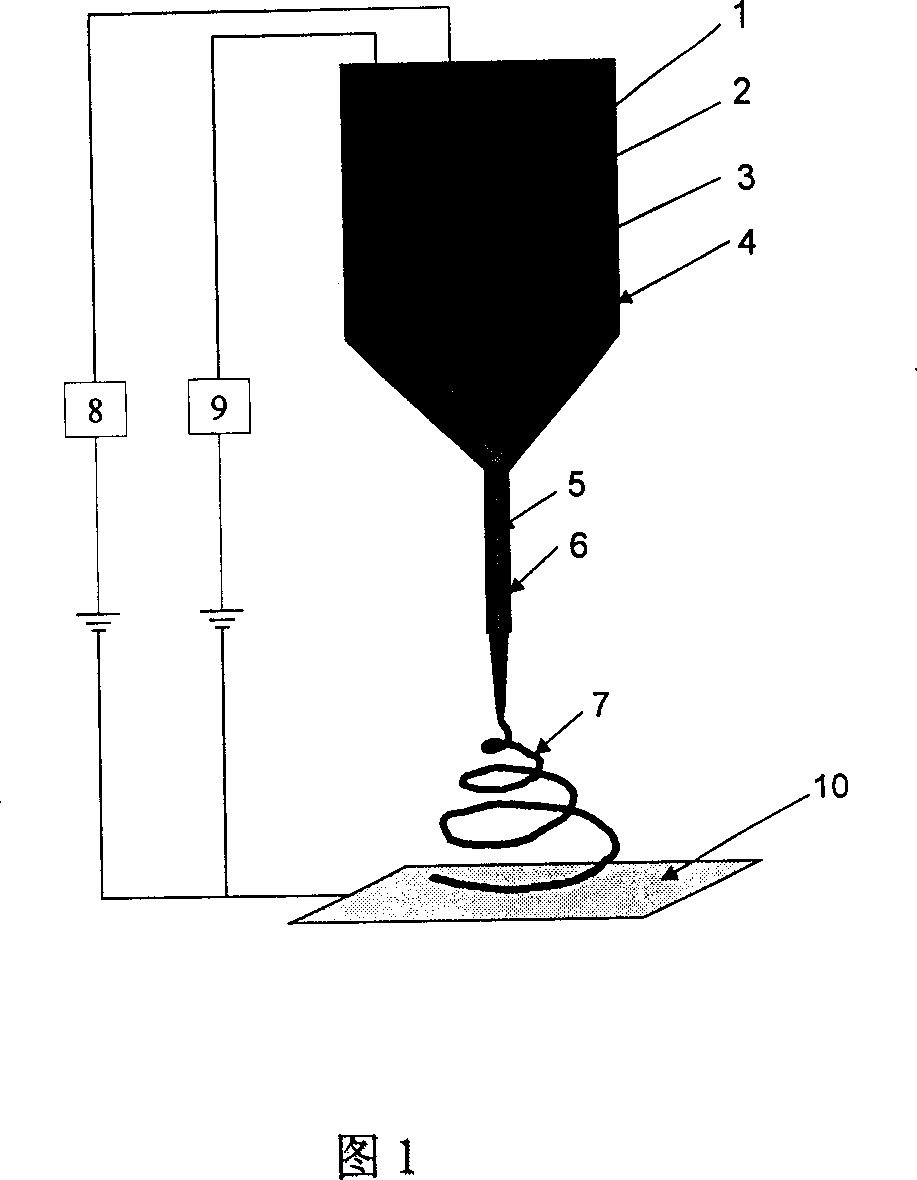

Method used

Image

Examples

Embodiment 1

[0021] A certain amount of Mefoxin (Mefoxin, a kind of antibiotic and anti-infection drug) is dissolved in a dichloromethane solution of amorphous polylactic acid (PDLA, molecular weight 100,000) at a concentration of 5% w / v, so that the weight percentage is 1%. The polylactic acid solution containing methexin will be used as the internal spinning solution. A solution of polycaprolactone dichloromethane-dimethylformamide (by weight ratio of 75:25) with a weight concentration of 13% and a molecular weight of 80,000 was used as the outer spinning solution. The inner diameter of the inner spray pipe (also known as spray needle) 5 is 0.3mm, and the outer diameter is 0.6mm; the inner diameter of the outer spray pipe (also called spray needle) 6 is 0.8mm, and the outer diameter is 1.2mm. The applied voltage was 18 kV. The two are coaxially co-spun on the grounded aluminum foil paper to obtain a nano-micron compress with controlled and continuous antibacterial effect.

Embodiment 2

[0023] Accurately weigh a certain amount of gelatin (Gelatin, type A), a derivative of natural macromolecular collagen, stir and dissolve it in a trifluoroethanol (2,2,2-Trifluoroethanol, TFE) organic solvent to obtain a concentration of 5%w A / v Gelatin / TFE solution was used as the surface layer material; and 10% w / v polycaprolactone (Polycaprolacton, PCL) / TFE solution was used as the core material. Coaxial co-spinning of the two (spinning conditions: electric field strength 0.7KV / cm, spacing between spinneret and receiving plate 15cm, environmental conditions: temperature 20°C, relative humidity: 75%, needle diameter as above), can get Monofilament horizontal surface modified ultrafine nano / micro fibers. Cell culture experiments showed that compared with electrospun non-hydrophilic polycaprolactone nano / microfibers with surface unfunctionalized, the surface functionalized polycaprolactone nano / microfiber membranes at the monofilament level had good cell affinity. harmony and...

Embodiment 3

[0025]Single-walled carbon nanotubes (SWNTs) were dispersed in water under ultrasonic conditions using sodium dodecyl sulfate (SDS) as a dispersant. After component optimization, 0.35wt% single-walled carbon nanotubes were uniformly dispersed in 1wt% sodium lauryl sulfate aqueous solution (used as spinning liquid). Polyvinyl alcohol (PVA) with a molecular weight of 120,000 and a degree of hydrolysis of 99% was dissolved in deionized water at 80° C. to prepare a 10 wt % polyvinyl alcohol solution (as an external spinning solution). Then the two are coaxially co-spun (25 kV high voltage, the needle diameter is the same as above, and the spacing is 10 cm), and the nanocomposite fiber containing carbon nanotube reinforcement is obtained, which improves the mechanical and electrical properties of the fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com