Zipper ribbon

A technology of zipper tape and fastener element, which is applied in the field of zipper tape and can solve the problem that fastener elements cannot be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

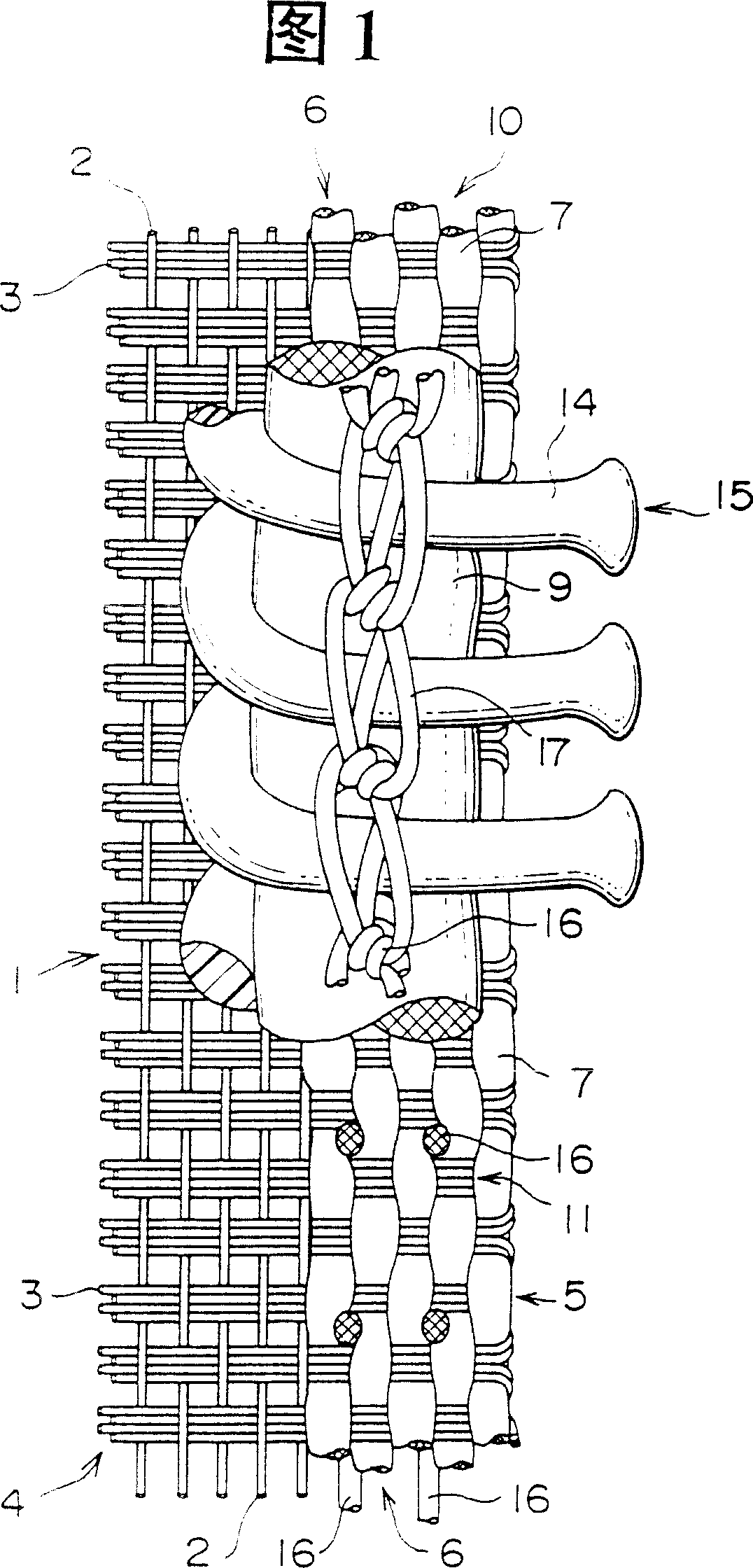

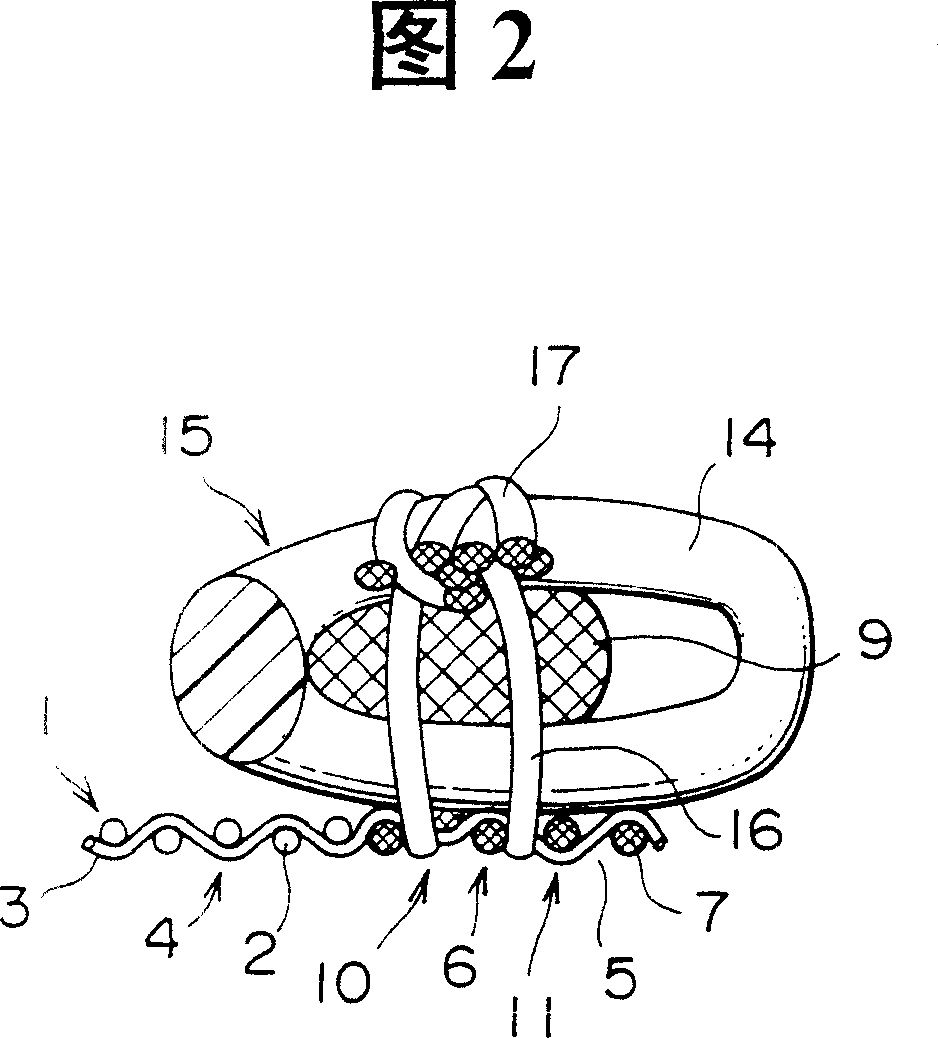

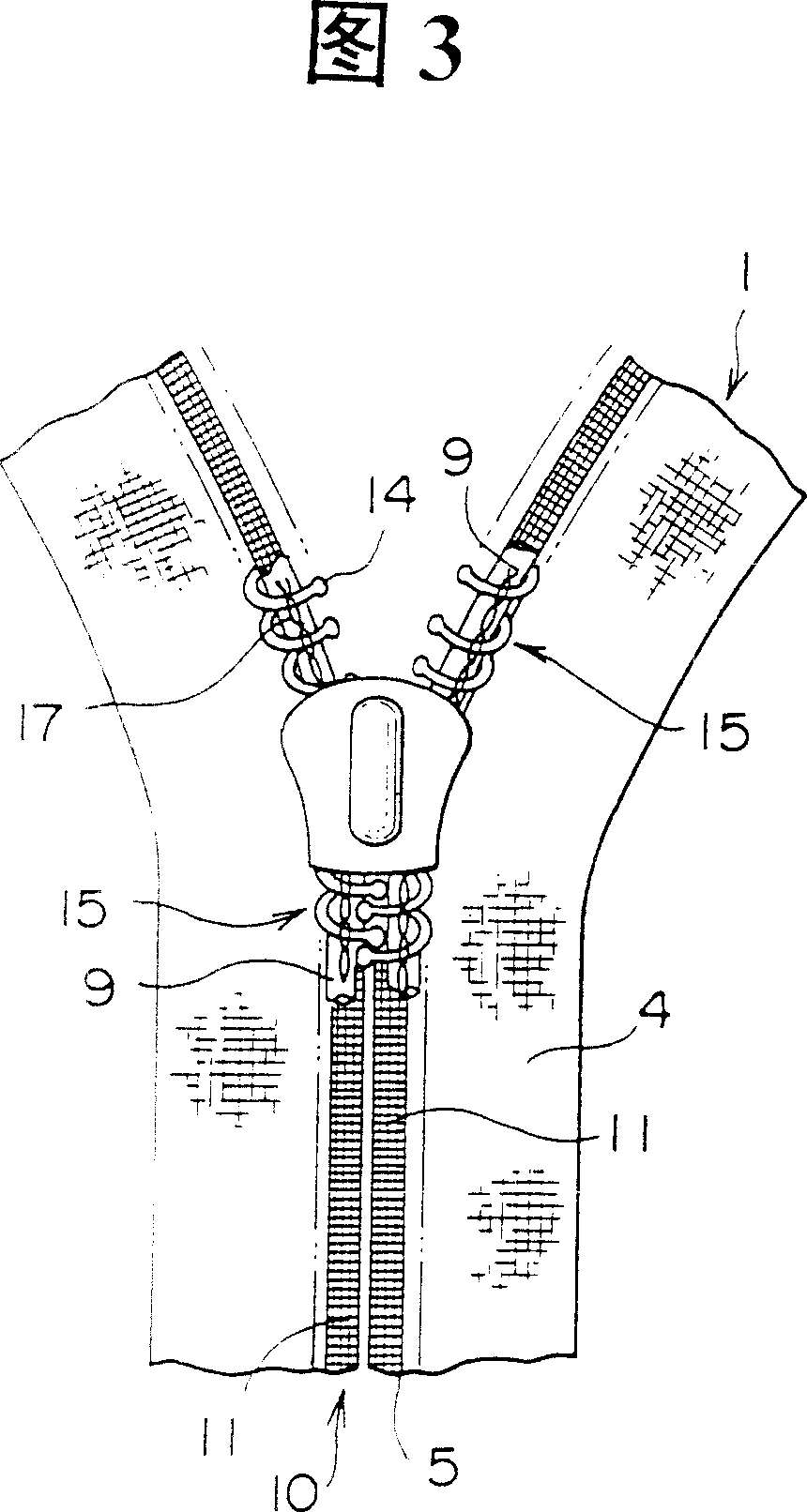

[0024] Embodiments of the fastener tape of the present invention will be described in detail below with reference to the accompanying drawings.

[0025] The zipper tape of the present invention is woven by a knitting machine. In the main part 4 of the zipper tape 1, polyamide-based or polyester-based transparent or translucent synthetic fiber monofilament threads are woven with warp threads 2 and double weft threads 3 of its woven fiber structure to form a transparent or translucent zipper with 1.

[0026] As shown in Figures 1 to 3, on the main part 4 of the middle part of the zipper tape 1 of the first embodiment, it is made of polyurethane-based synthetic fibers such as nylon 6 or nylon 66, or such as polyethylene terephthalate. Transparent or translucent monofilament threads made of polyester-based synthetic fibers are used as warp threads 2 , and transparent or translucent monofilament threads made of polyamide-based or polyester-based synthetic fibers are used as weft t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com