Fiberizer

A technology of a refiner and a grinding disc, which is used in pulp beating/refining methods, textiles and papermaking, fiber raw material processing, etc. and other problems, to achieve the effect of reducing pollution, reducing floor space, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings.

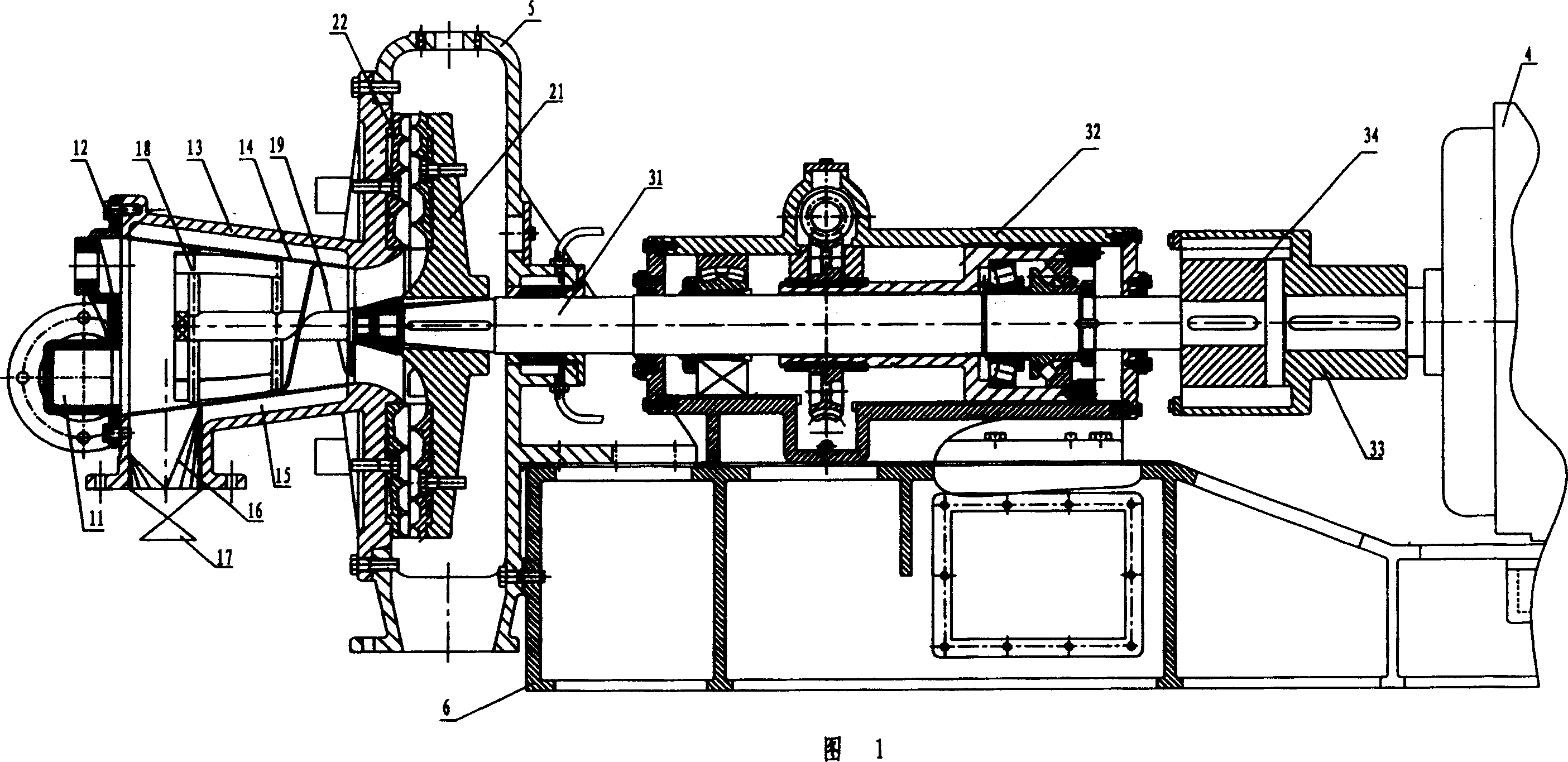

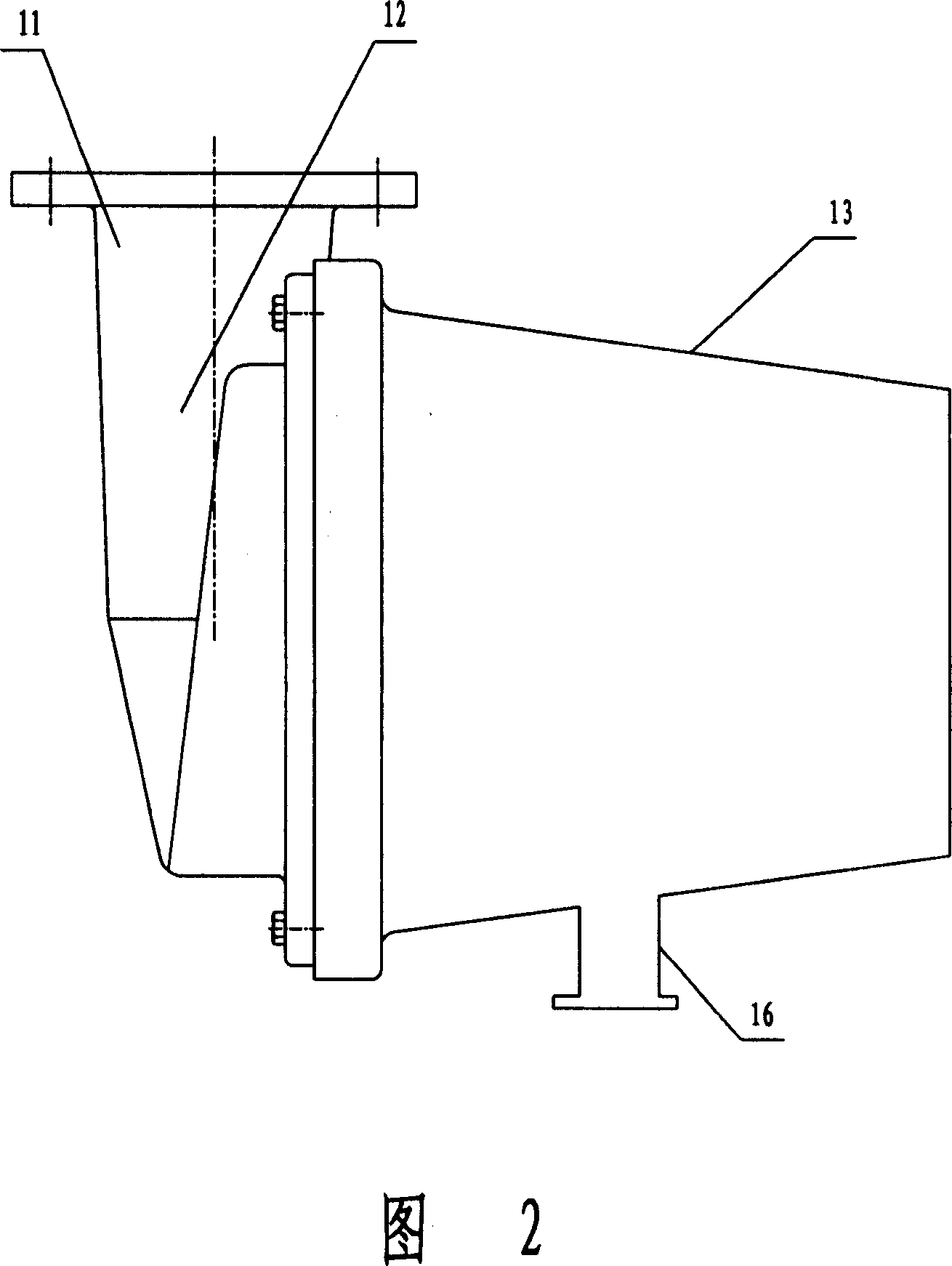

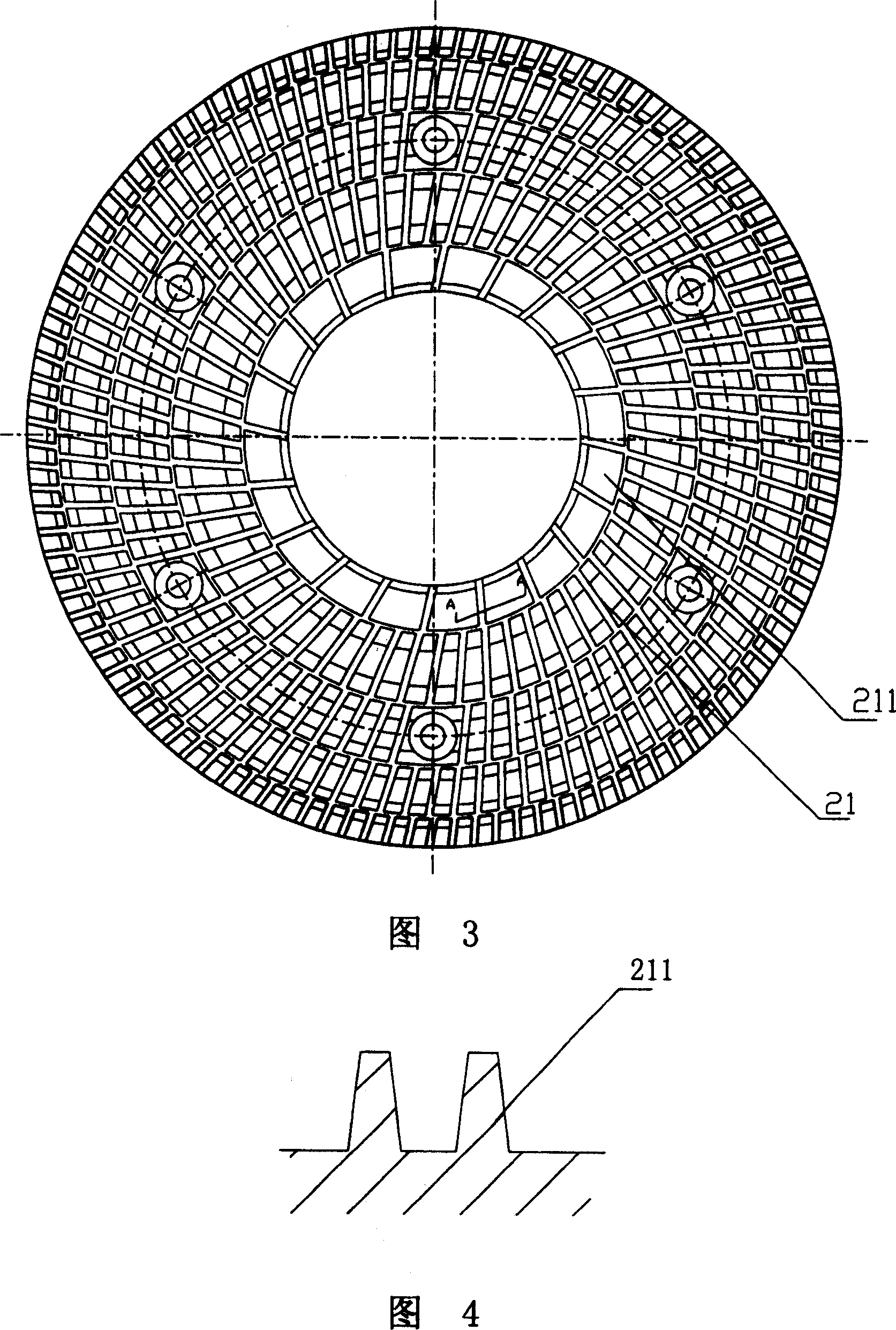

[0032]As shown in Figure 1, a kind of refiner of the present invention, it comprises the milling disc mechanism, transmission mechanism and electric motor that are connected successively, and milling disc mechanism is installed in the casing 5 with screw, and casing 5 and transmission mechanism are all installed in with screw On the machine base 6; the millstone mechanism includes a rotating millstone 21 and a fixed millstone 22 cooperating with the rotating millstone 21. The rotating millstone 21 is installed on one end of the main shaft 31 of the transmission mechanism, and the fixed millstone 22 is installed on the inner wall of the casing 5. The transmission mechanism mainly includes the main shaft 31. Bearing housing 32, driving coupling 33 and driven coupling 34. The driven coupling 34 is installed on the main shaft 31 of the refiner and looped in the dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com