Method for decreasing by gasoline olefin and producing propylene

A gasoline and propylene technology, which is applied in the petroleum industry, cracking, catalytic cracking, etc., can solve the problems of immature process technology, reduce the olefin content of catalytic gasoline, complex process, etc., and achieve excellent hydrothermal stability, excellent anti-coking performance, The effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

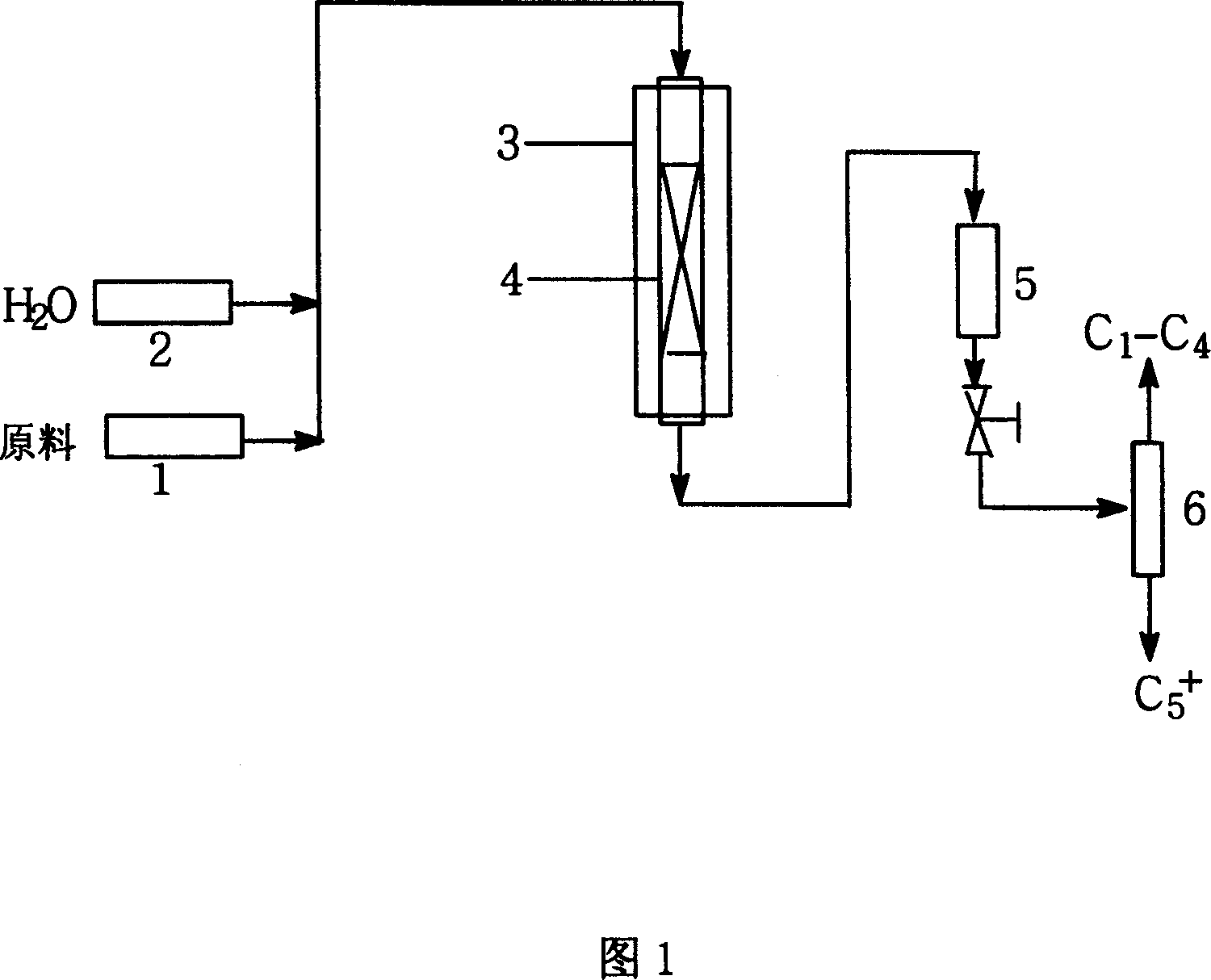

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of Catalyst A

[0031] 50g ZRP molecular sieve (provided by Beijing Wanshuyuan Economic, Technical and Trade Center, SiO 2 / Al 2 O 3 >200), 50g silicon oxide (specific surface area>200m 2 / g), 2g extrusion aid mixed; after mixing, add an appropriate amount of dilute nitric acid, stir evenly, extrude into a 2mm cylindrical shape, and cut into 2-3mm; dry at 100℃ for 10 hours, then calcined for 6 hours, take out and cool To room temperature for later use. The catalyst prepared in this way is designated as catalyst A.

Embodiment 2

[0032] Example 2 Preparation of Catalyst B

[0033] 50g ZRP molecular sieve (SiO 2 / Al 2 O 3 >200), 40g silicon oxide, 10g magnesium oxide and 2g extrusion aid are mixed, and after mixing, add an appropriate amount of dilute nitric acid. The other operation methods are the same as in Example 1. The catalyst prepared in this way is designated as catalyst B.

Embodiment 3

[0034] Example 3 Preparation of Catalyst C

[0035] 50g ZRP molecular sieve (SiO 2 / Al 2 O 3 >200), 50g silicon oxide, 5g magnesium oxide, 5g zirconium oxide and 2g extrusion aid are mixed, and after mixing, add an appropriate amount of dilute nitric acid. The other operation methods are the same as in Example 1. The catalyst prepared in this way is designated as catalyst C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com