Method for manufacturing a solid-state image sensing device, such as a ccd

A technology of solid-state imaging element and manufacturing method, which is applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., and can solve problems such as inability to reproduce colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

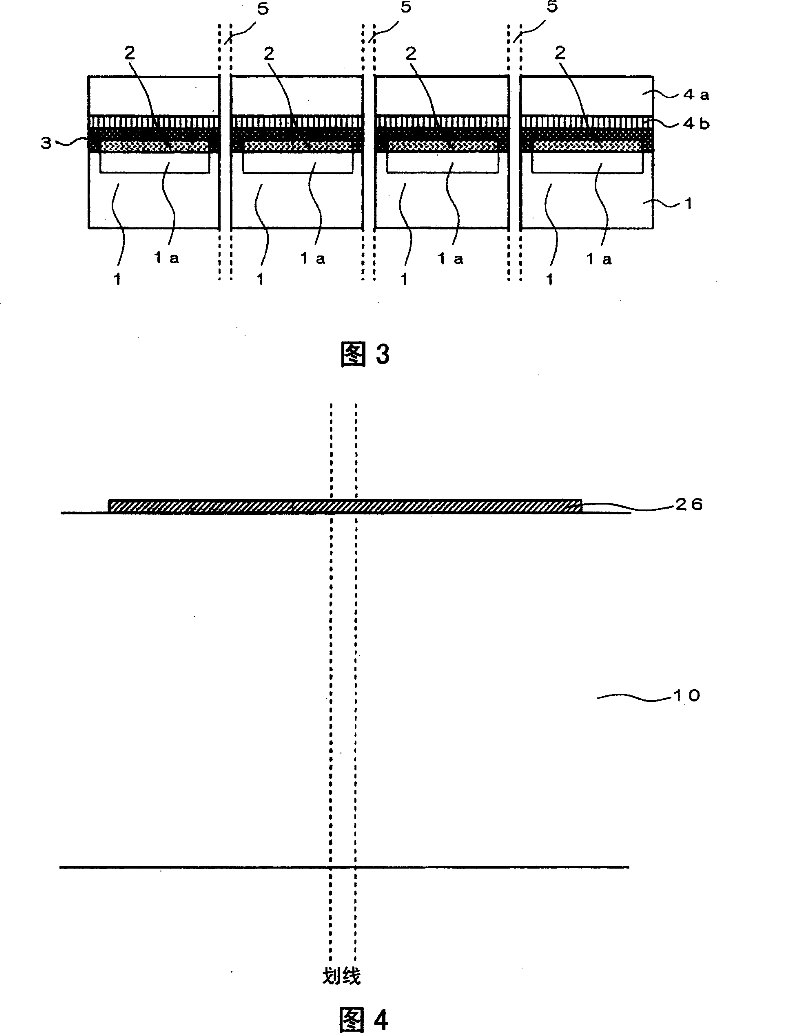

[0018] 1 to 3 are cross-sectional views showing the sequence of steps of the first embodiment of the method for manufacturing a solid-state imaging device according to the present invention. This embodiment is constituted by a light receiving element forming step, an infrared cut filter lamination step, and a dicing step.

[0019] First, in the light-receiving element forming step, as shown in FIG. 1 , a light-receiving element is formed in each region 1a divided by scribe lines on the surface of the semiconductor substrate 1 . The color filter 2 is stacked so as to cover the formation region 1 a of the light receiving element. The semiconductor substrate 1 can be made of common semiconductor materials such as silicon and gallium arsenide. For example, an integrated circuit of a CCD as a light receiving element can be formed by a well-known semiconductor process.

[0020] In the infrared cut filter lamination step, as shown in FIG. 2 , the infrared cut filter is bonded and fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com