Manufacturing method of rotor

A manufacturing method and rotor technology, which can be used in the manufacture of motor generators, stator/rotor bodies, magnetic circuit rotating parts, etc., can solve the problems of difficulty in controlling the placement of adhesives, and prevent the placement of adhesives from becoming difficult. , The effect of improving insertability and preventing an increase in the number of processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the present invention will be described below based on the drawings.

[0031] [Structure of the rotor of the first embodiment]

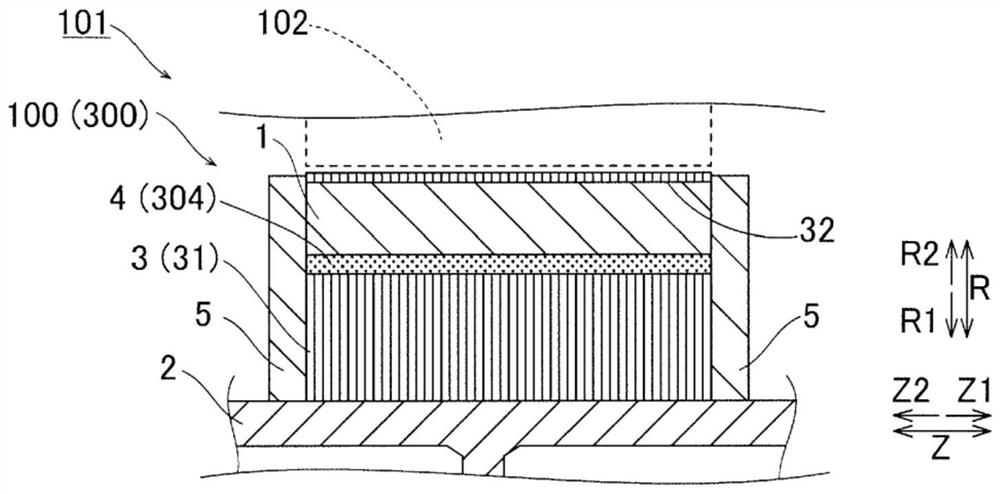

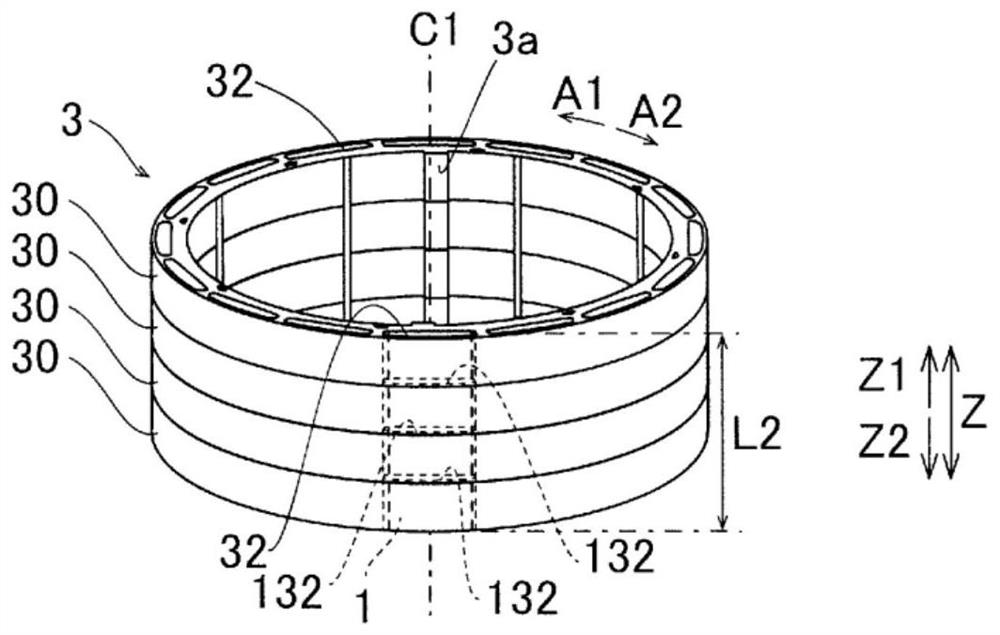

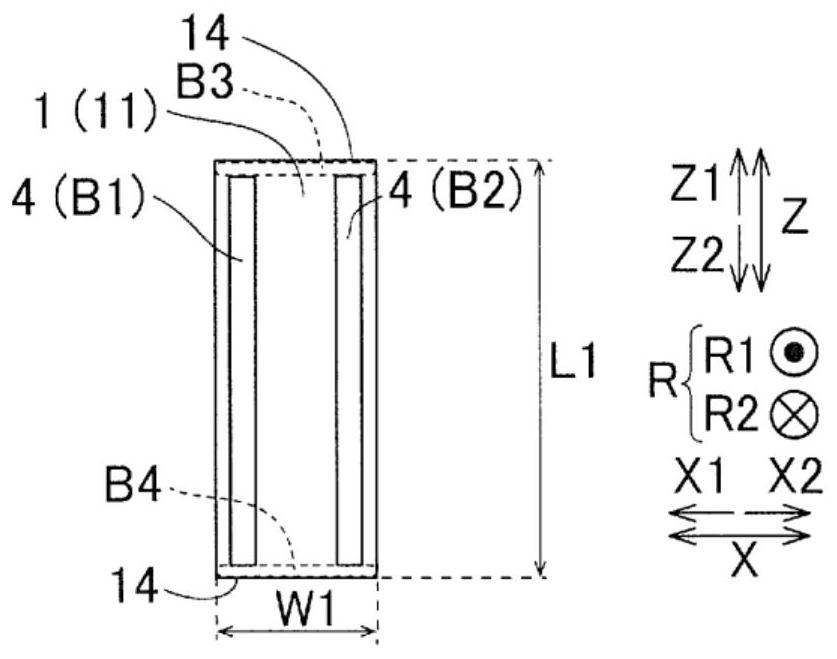

[0032] refer to Figure 1 to Figure 8 The structure of the rotor 100 of the first embodiment will be described.

[0033] In addition, in the specification of the present application, "rotating electric machine" is described as a concept including any one of a motor (electric motor), a generator (generator), and a motor generator that functions as both a motor and a generator as needed. For example, the rotary electric machine 101 is configured in the form of a traction motor used in a hybrid vehicle or an electric vehicle.

[0034] In addition, in the specification of this application, "rotor rotation axis direction" or "axial direction" refers to the rotation axis direction of the rotor 100 (along the axis C1 (refer to figure 2 ) direction; and figure 1 in the direction parallel to the Z-axis). In addition, "circumferenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com