Variable stroke engine and working method thereof

A four-stroke engine and engine technology, applied in the direction of engine control, machine/engine, mechanical equipment, etc., can solve problems such as unqualified and obstacles to put into practice

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

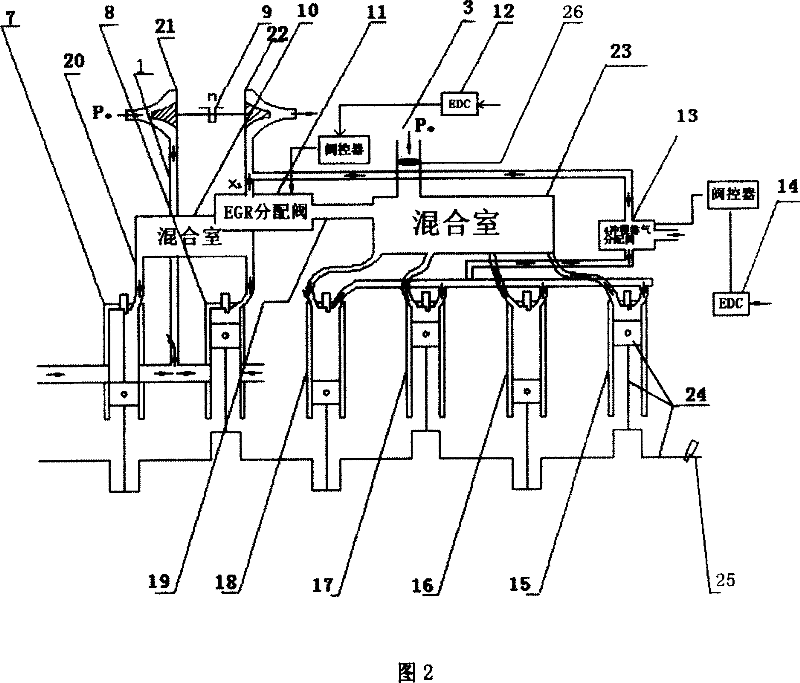

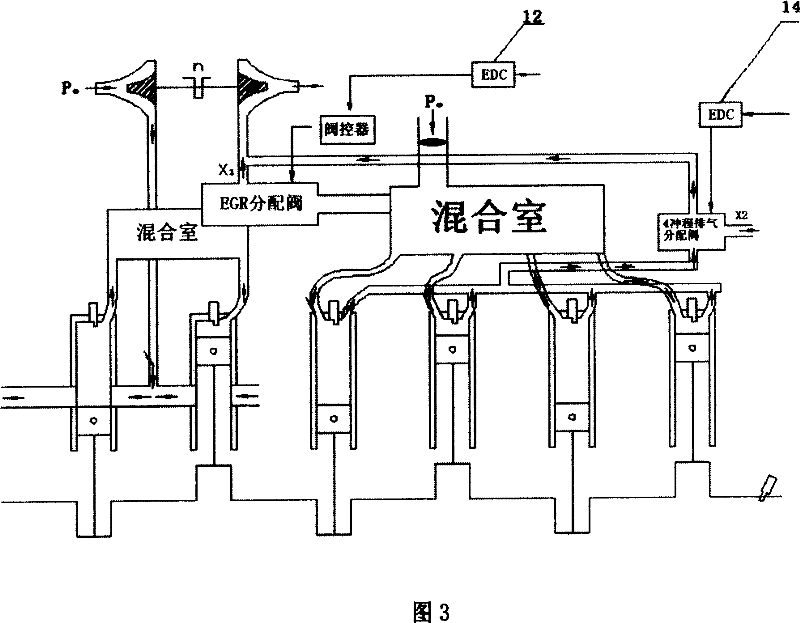

[0053] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0054] Fig. 1 is the basic pipeline and air valve diagram of the present invention. The two-stroke intake pipe 1 shown in Fig. 1 obtains the fresh air blown into the cylinder from the intake pump of the exhaust gas turbocharger, and guides it to the two two-stroke cylinders, after the gas and fuel are mixed and burned The exhaust gas is discharged from the two-stroke exhaust pipe 20 shown in accompanying drawing 2, first enters a unified mixing chamber 10 in Fig. 2, and then passes through the distribution of the EGR distribution valve 11 in Fig. 2, and part of it enters the exhaust gas turbocharger in Fig. 2 The power input end 22 of the compressor drives the turbine, and the other part enters the intake air of the four-stroke cylinder to participate in the combustion in the cylinder, so as to realize exhaust gas recirculation and improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com