Vacuum air removing technology for austenite stainless steel

An austenitic stainless steel and vacuum technology, which is applied in the field of degassing treatment, can solve the problems that the degassing effect of materials cannot be guaranteed, the outgassing rate of system materials increases, and the vacuum degree of the system cannot be improved, so as to avoid cooling too slow and degassing High gas efficiency and the effect of avoiding oil vapor pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing description:

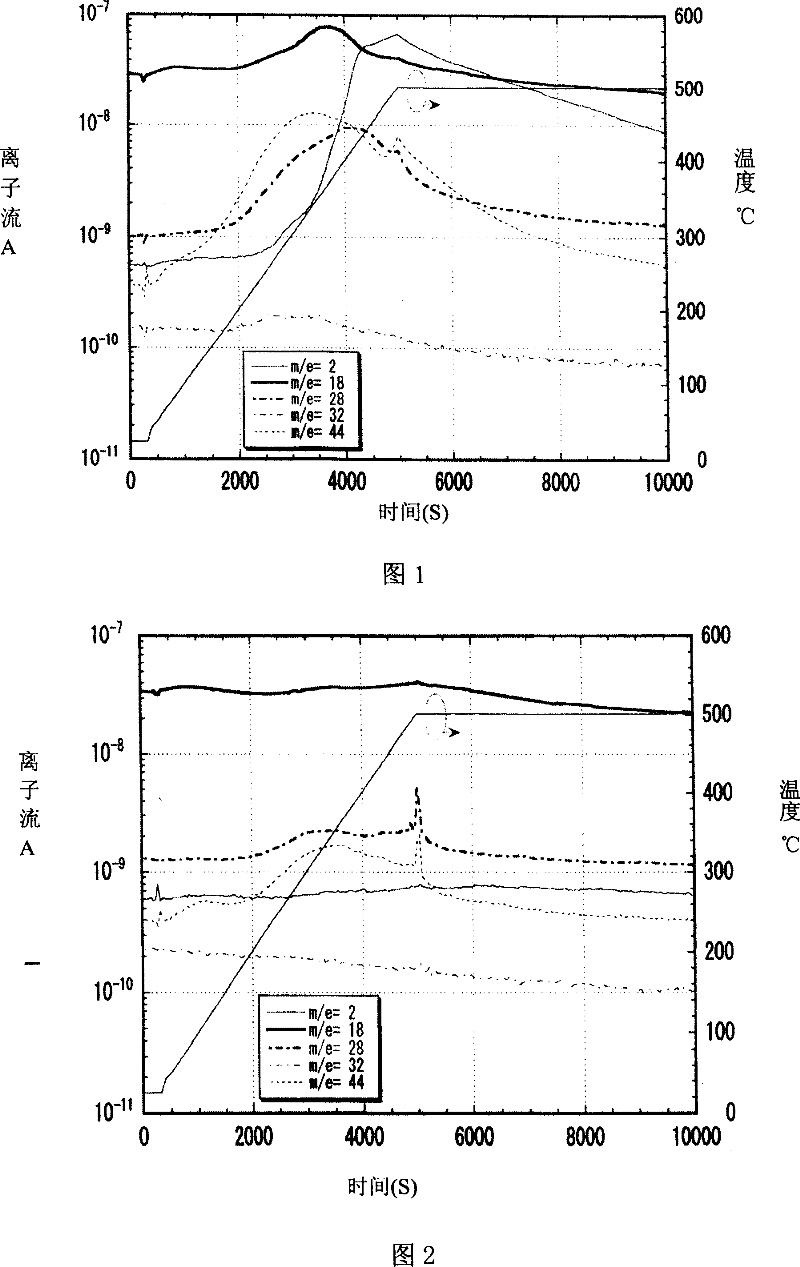

[0018] The experiment carried out in accompanying drawings 1 and 2 is to heat the two samples to 500° C. respectively, and then keep them warm for a period of time while observing the outgassing situation of the samples. It can be seen from the figure that the sample starts to outgas during the heating process, and the outgassing volume without degassing is obviously larger than that degassed by the present invention. where H 2 The most obvious difference is 2 orders of magnitude (100 times). Water vapor is mainly adsorbed on the surface, so there is little difference between degassing and degassing, and it will be removed by on-site baking in the future. Oxygen is also mainly adsorbed on the surface, and it is easy to be pumped away, so the degassing mainly solves the large amount of H dissolved in the metal. 2 , CO and CO 2 The problem.

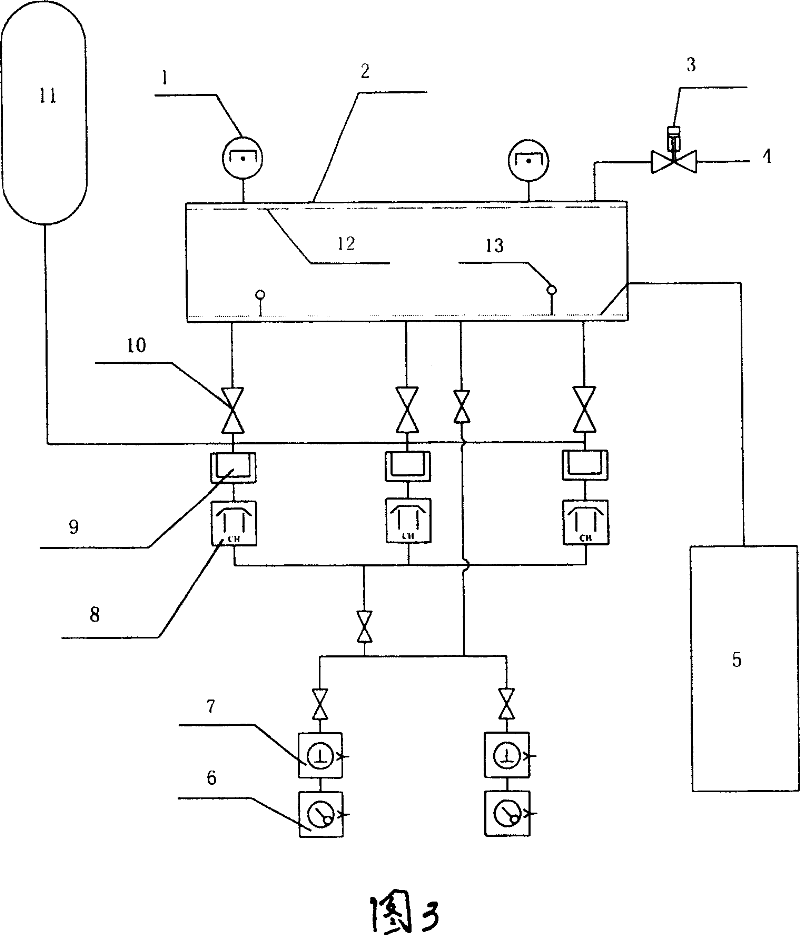

[0019] A specific embodiment of the present invention uses auste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com