Supehigh strength parallel steel wire durable cables

An ultra-high-strength, steel wire technology, applied in the field of cables, can solve the problems of weak corrosion resistance and poor durability, and achieve the effects of good fatigue resistance, convenient construction and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

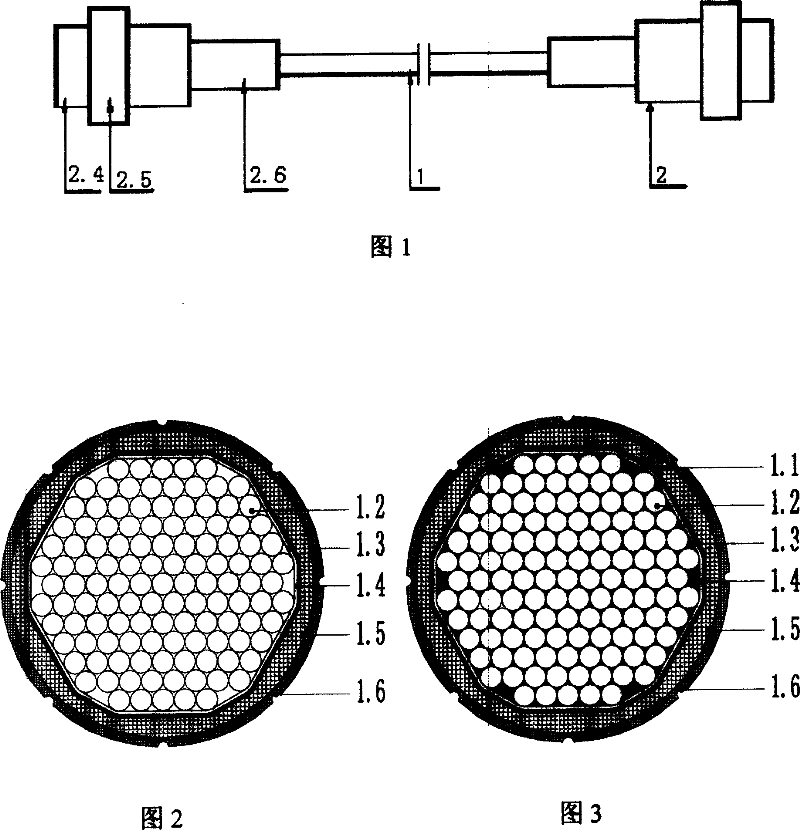

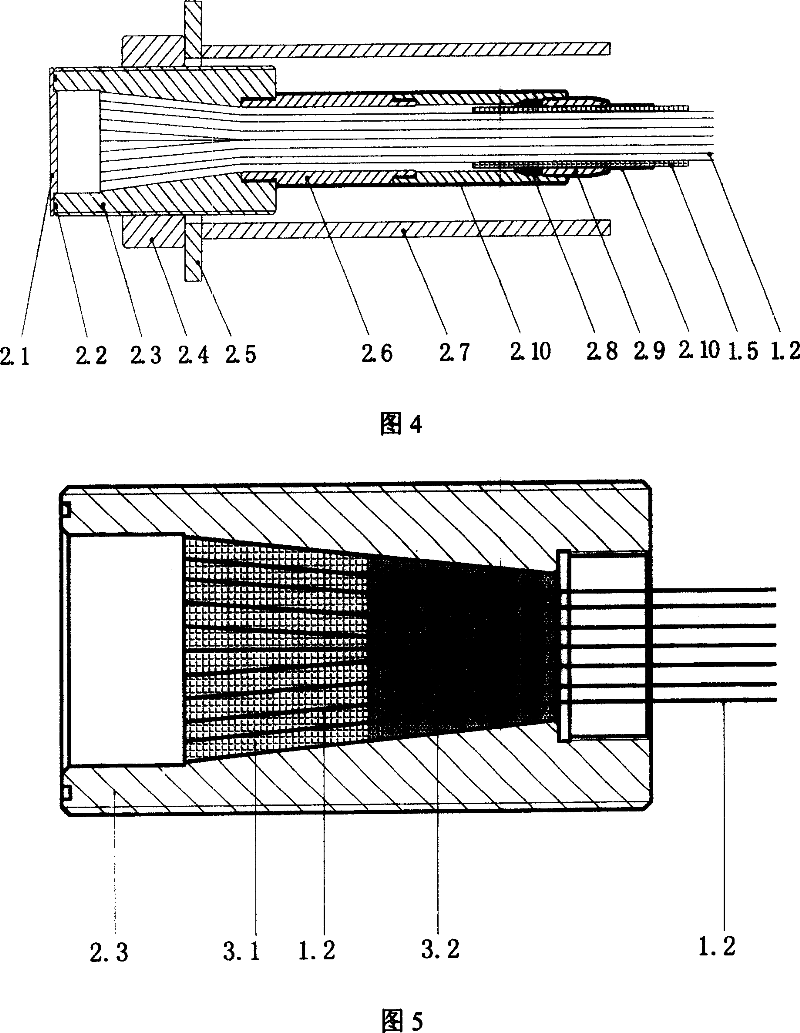

[0021] The present invention is an ultra-high-strength parallel steel wire durable cable. The structure of the finished cable is shown in FIG. The anchorage 2 is formed by connecting an anchor cup 2.3, an anchor ring 2.4 and a connecting cylinder 2.6.

[0022] The cross-section of the steel strands of the cable is closely arranged in a regular hexagon or a hexagon with missing corners, and is formed by twisting. There are two types of cable body structures, and the cross-sectional schematic diagrams are shown in Figure 2 and Figure 3 respectively.

[0023] Referring to Figure 2, the outer surface of the steel wire bundle 1.2 of the cable body 1 is first wound with a perfluorinated film tape 1.3, then wound with a fiber reinforced polyester tape 1.4 to form, and then extruded a double-layer high-density polyethylene sheath 1.5, and the surface of the cable body is sealed. The embossing process forms embossed indentations 1.6.

[0024] Referring to Fig. 3, the gap between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com