Yeast low oxygen SBR process and device aimed to high concentrated organic wastewater

A technology for organic wastewater and yeast, applied in the field of yeast hypoxic SBR process, can solve the problems that have not yet been seen, high pretreatment cost, complex process flow, etc., achieve low sludge output, save operating costs, and have a wide range of applications. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

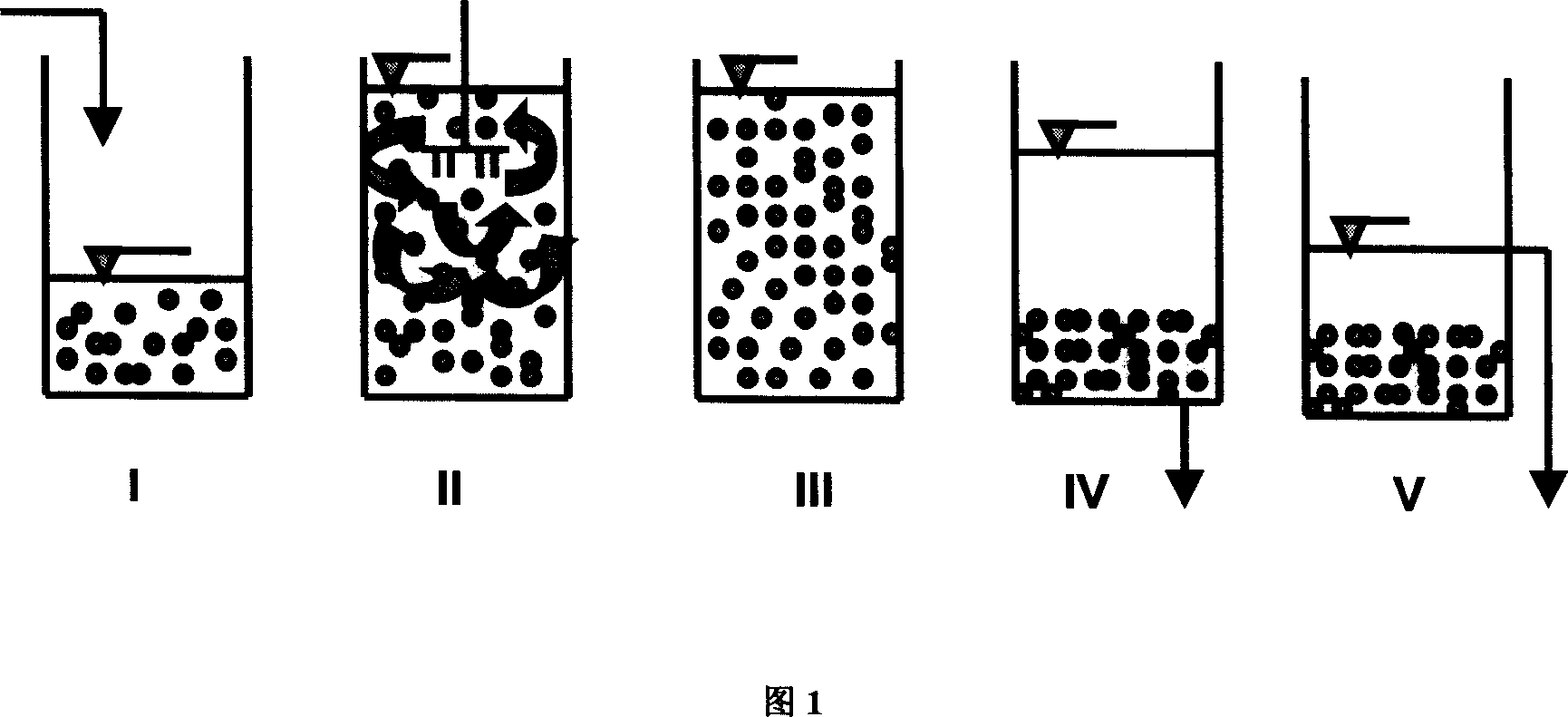

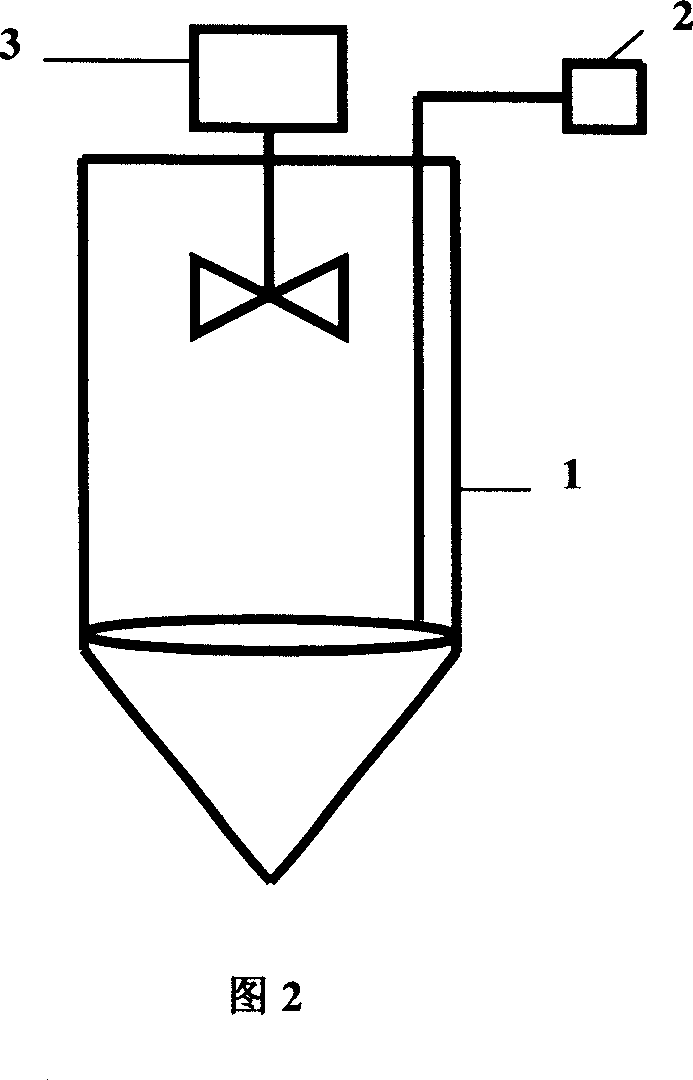

[0019] The water quality characteristics of an antibiotic production wastewater are shown in Table 1. It is a typical high-nitrogen type and high-concentration organic wastewater. The prior art type needs to add a pretreatment denitrification process before the biological treatment process. The present invention inoculates artificially selected yeast strains with excellent sedimentation properties in the original SBR reaction tank, and starts batch culture. When the MLSS reaches 15g / L, it is directly fed into undiluted waste water to start intermittent aeration treatment. The amount of aeration controls the dissolved oxygen in the SBR reaction tank to ≤0.5mg / L. The operation steps of one cycle are: water intake→aeration→sedimentation→sludge discharge→aeration→sedimentation→decanting water. The hydraulic retention time is 2-3d. The effluent indicators are shown in Table 1.

[0020] COD Cr (mg / L)

Embodiment 2

[0022] The water quality characteristics of an oil refinery wastewater are shown in Table 2, which is a typical high-oil type and high-concentration organic wastewater. In the present invention, the undiluted waste water is used as a culture medium to obtain a yeast microbial community with excellent sedimentation properties by adopting a batch culture and screening scheme, and a microbial provenance for use in the field is obtained after aerobic culture. The microbial source is added to the SBR reaction tank that has been added to this type of organic wastewater. The start-up period is 6 days, and then the undiluted wastewater is introduced to start the treatment. The dissolved oxygen in the SBR reaction tank is controlled to be ≤0.5 by controlling the amount of aeration. mg / L, the operation steps of one cycle are: water intake→aeration→sedimentation→sludge discharge→aeration→sedimentation→sludge discharge→aeration→sedimentation→sludge discharge→aeration→sedimentation→decantin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com