Gear spin pressure forming method and its device

A spinning forming and gear technology, applied in the field of gear spinning forming method and its device, can solve the problems of equipment control difficulty and manufacturing cost increase, synchronization and accuracy problems, increase of hydraulic control system, etc., to eliminate discontinuity , high processing cost, improve the effect of mechanical equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

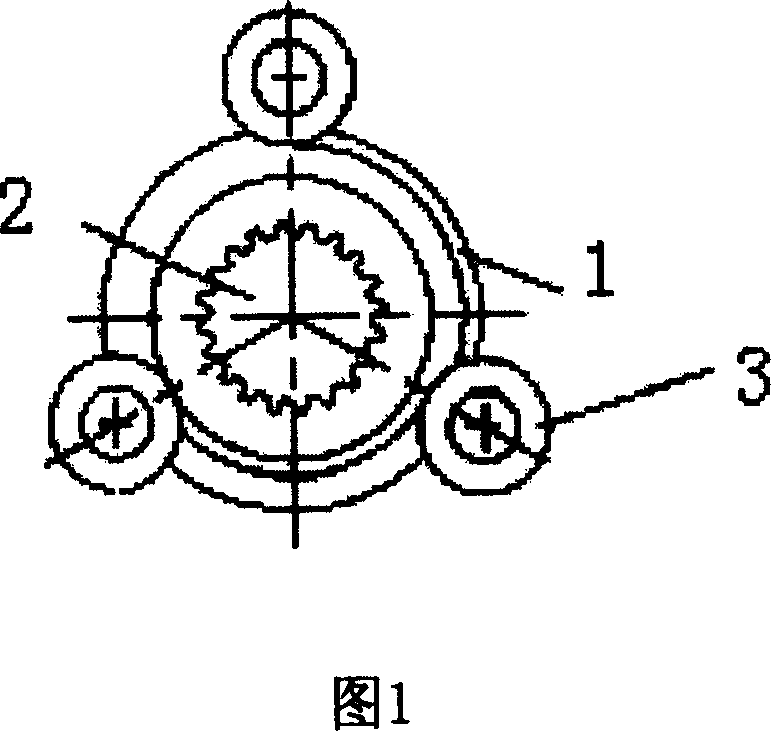

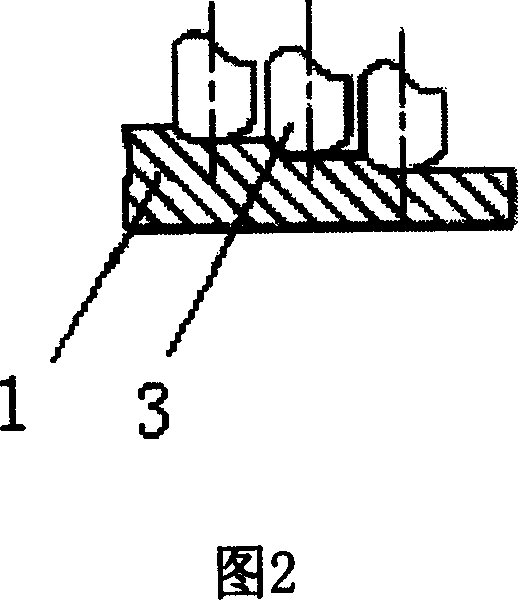

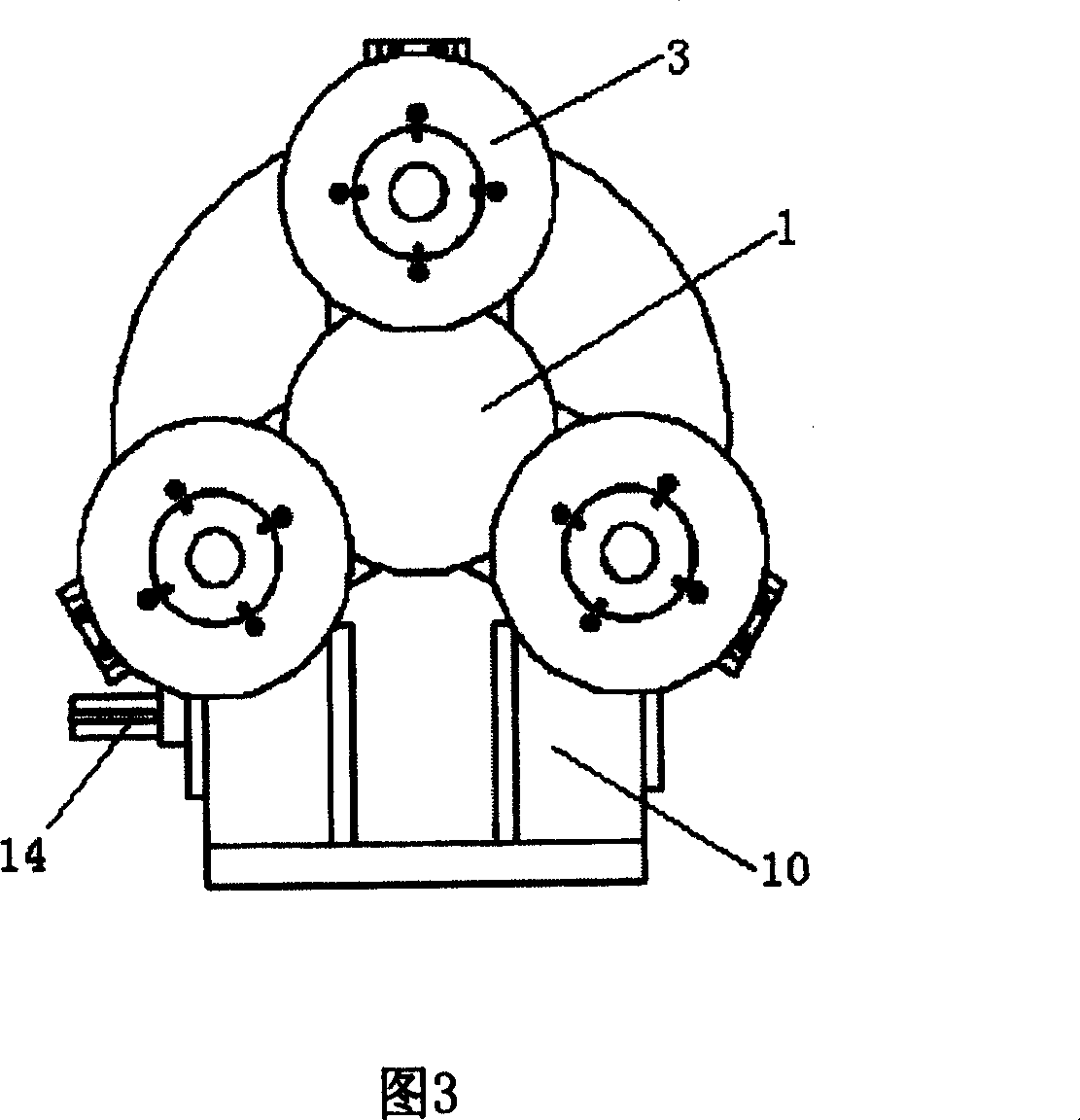

[0031] As shown in Figures 1 and 2, the gear spinning forming method of the present invention is as follows: the cup-shaped blank 1 is set on the external tooth-shaped mandrel 2 that rotates with the main shaft, and the three rotary wheels 3 are formed along the circumferential direction of the blank's outer peripheral surface. The angles are evenly set at intervals of 120°, and there are axial and radial offsets between each other. The servo motor drives the three rotary wheels 3 through the worm 14, the worm wheel 15 and the Archimedes spiral disc 6 to perform radial feed movement. Through the movement of the rotary wheel 3 and pressurization on the blank 1, the blank 1 is plastically deformed to become an internal gear.

[0032] The cup-shaped blank 1 is processed by sheet metal stamping and drawing or deep-drawing spinning. Since the volume distribution of deformed metal during gear spinning is relatively large, thick-walled blanks must be used for gear spinning.

[0033] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com