Plasma display device and method for producing its front base plate

A display and front substrate technology, which is applied in the manufacture of discharge tubes/lamps, electrode systems, cold cathodes, etc., can solve the problems of human body damage, lower energy utilization rate, and reduce the brightness of plasma displays, so as to avoid damage, The effect of increasing brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

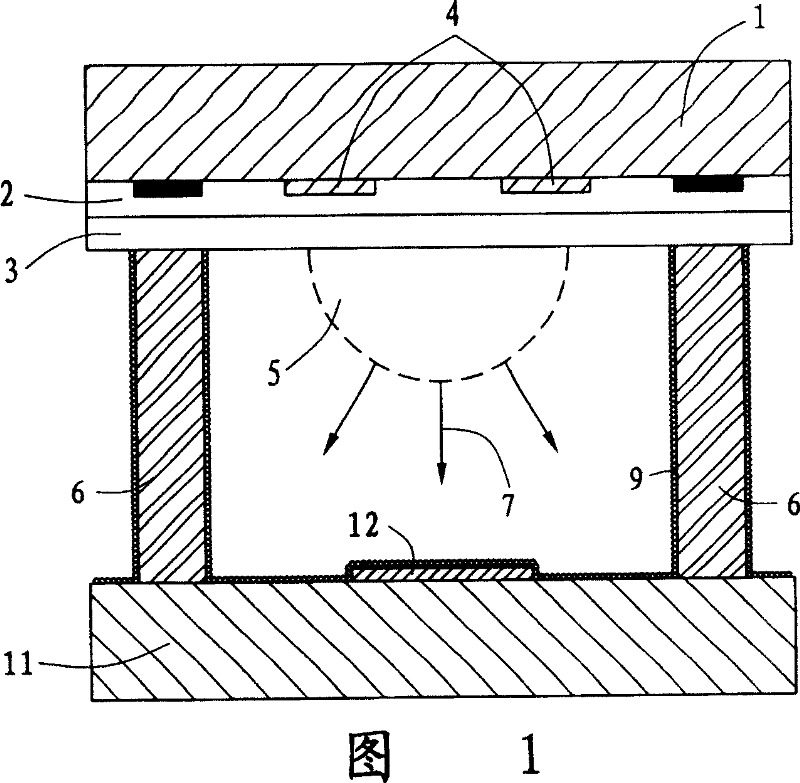

[0012] Please refer to FIG. 2, the plasma display 400 of the present invention includes a front substrate 100, a rear substrate 200 and a plurality of discharge grooves 300, wherein the front substrate 100 is opposite to the rear substrate 200, and the plurality of discharge grooves 300 are located on the between the front substrate 100 and the rear substrate 200 .

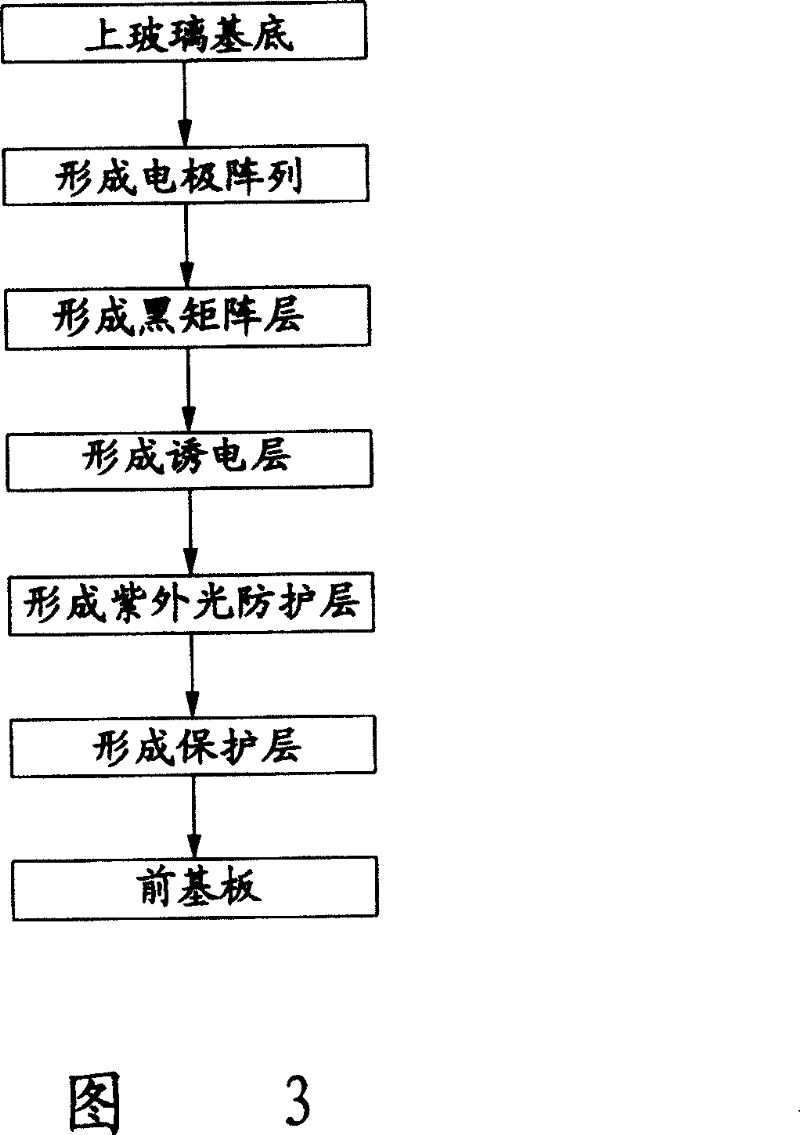

[0013] The front substrate 100 includes an upper glass substrate 102, an electrode group array 112, a black matrix 104, a dielectric layer 106 and a protective layer 110, wherein the upper glass substrate 102 is used to carry the electrode group array 112, black matrix 104 , the dielectric layer 106 and the protection layer 110 . The electrode set array 112 and the black matrix 104 are deposited on the upper glass substrate 102 , and the dielectric layer 106 and the protective layer 110 are sequentially covered on the electrode set array 112 and the black matrix 104 . Wherein, the electrode group array 112 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com