Water-blending process device

A technology of water flow and flow, which is applied in the direction of wellbore/well valve device, production fluid, wellbore/well parts, etc. It can solve the problems of shortening the service life of the valve, failing to achieve the expected effect, and easy to shatter the valve. , to achieve the effect of rapid adjustment, good sealing performance, quick installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

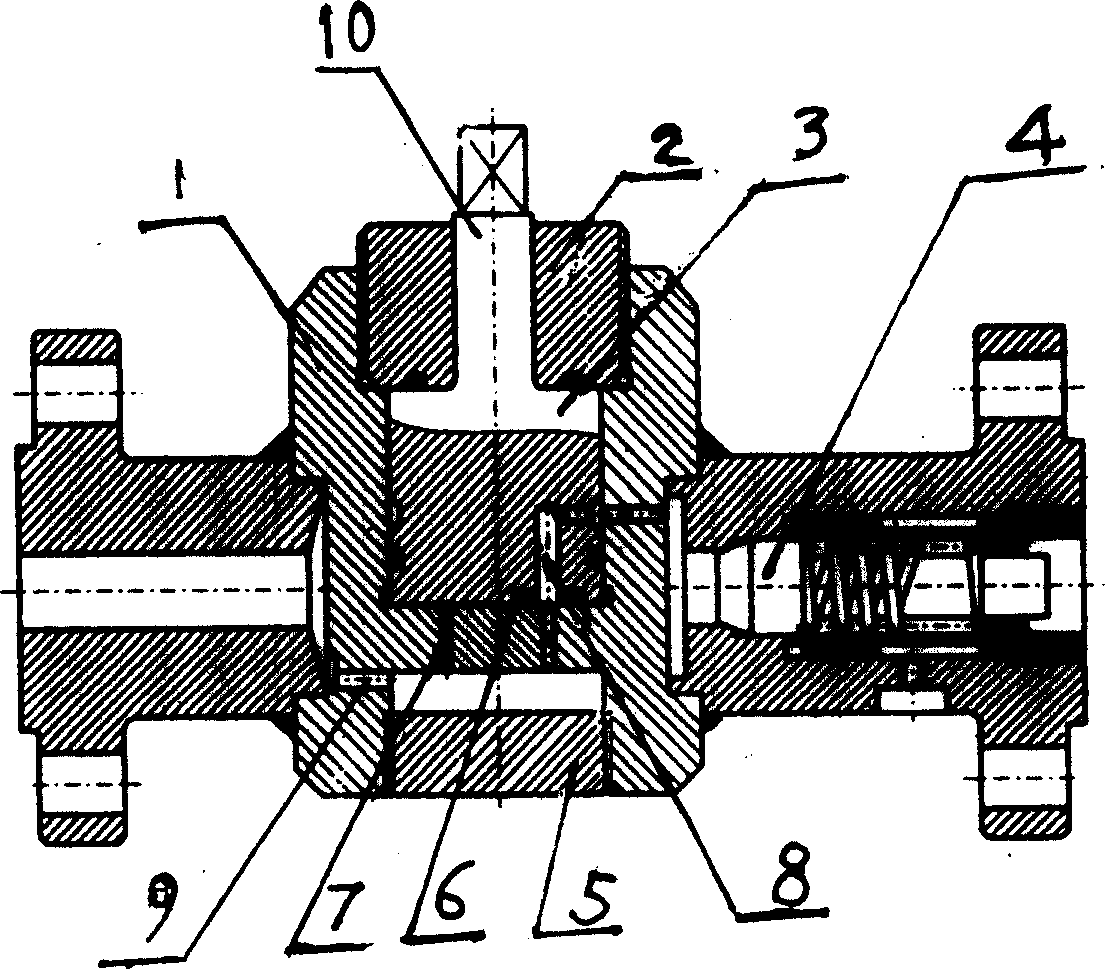

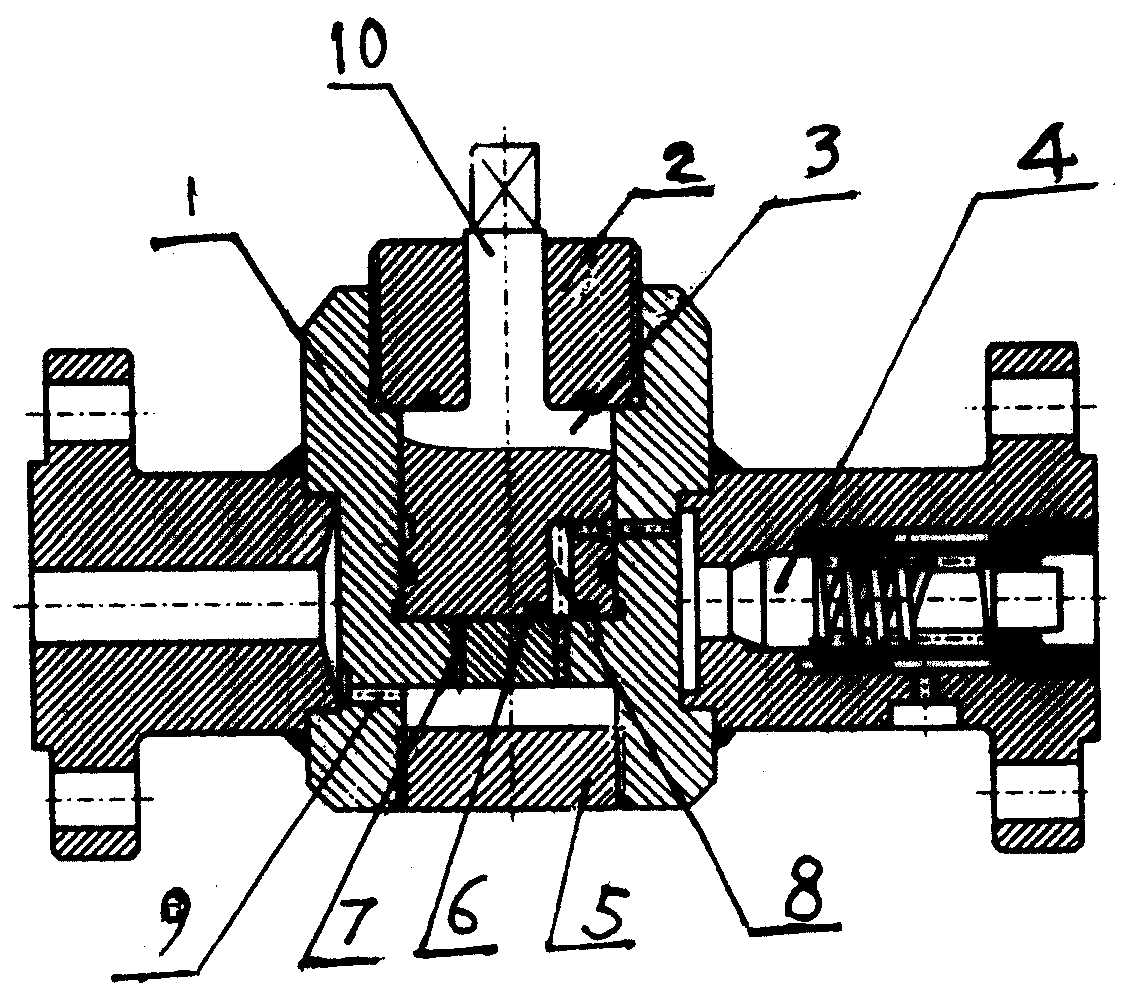

[0013] Referring to the accompanying drawings, a water mixing process device includes a housing 1 and a check valve 4 connected to the housing 1. The housing 1 is cylindrical and has an upper and lower chamber structure, and the partitions of the upper and lower chambers are circumferentially There are 1 or 2-12 flow channels 7 with different apertures (shown as 6 in the figure), the lower cavity is provided with a water flow channel 9 connected with the water inlet channel of the shell 1, and a bottom cover is installed at the end 5. The rotating body 3 is installed in the upper cavity, and the rotating body is provided with a rotating rod 10 integrated with it, and the rotating body is provided with a check valve installed on the flow channels on the partition plate and the outlet of the shell. There are 4 connected vertically folded channels 8, and the upper end of the housing 1 is provided with a sealing cover 2.

[0014] The rotating body 3 of the present invention has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com