Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55 results about "Angel wing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Angel wing, also known as airplane wing, slipped wing, crooked wing, and drooped wing, is a syndrome that affects primarily aquatic birds, such as geese and ducks, in which the last joint of the wing is twisted with the wing feathers pointing out laterally, instead of lying against the body. Males develop it more frequently than females. It has also been reported in goshawks, bustard chicks, and psittacine birds (budgerigars, macaws, and conures).

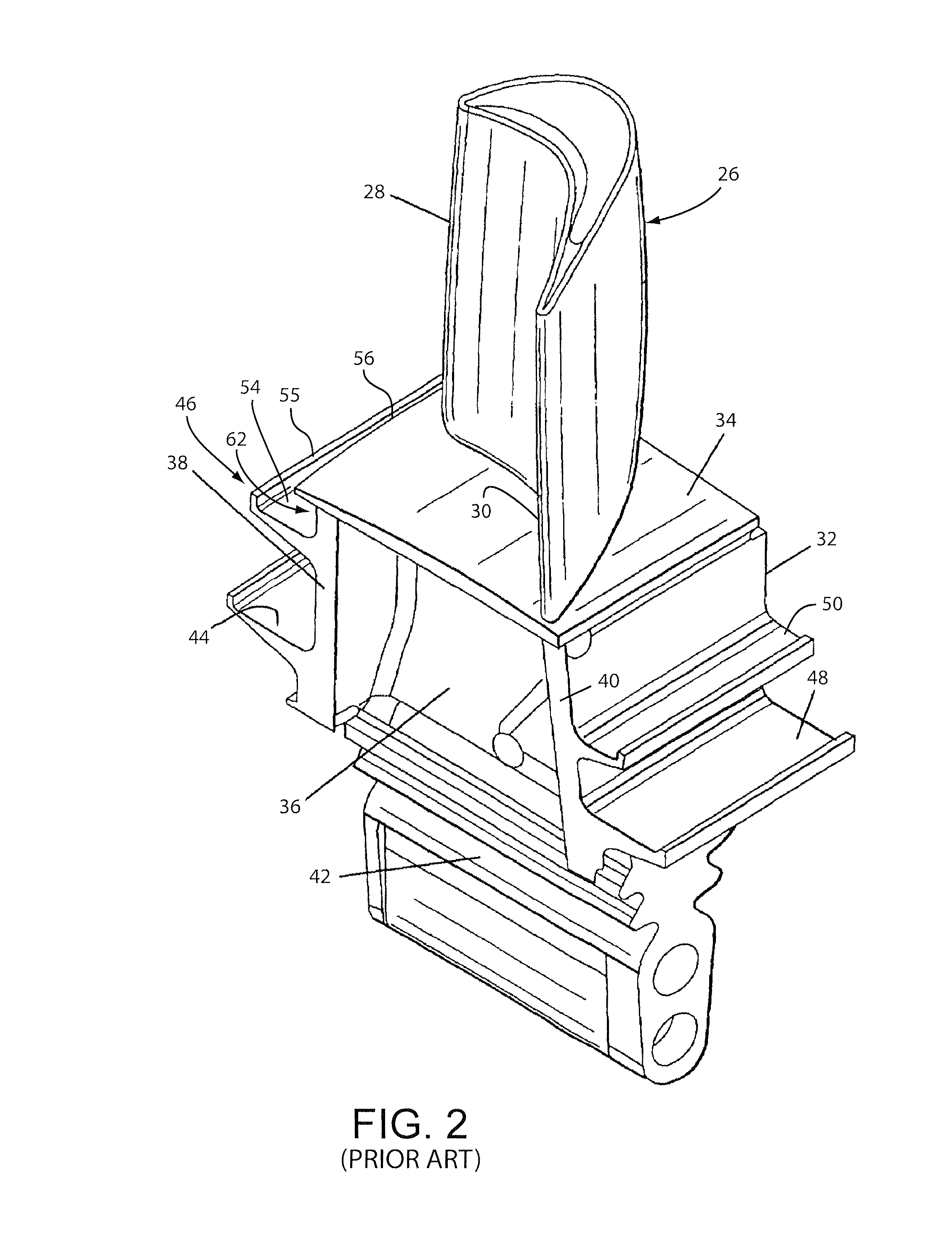

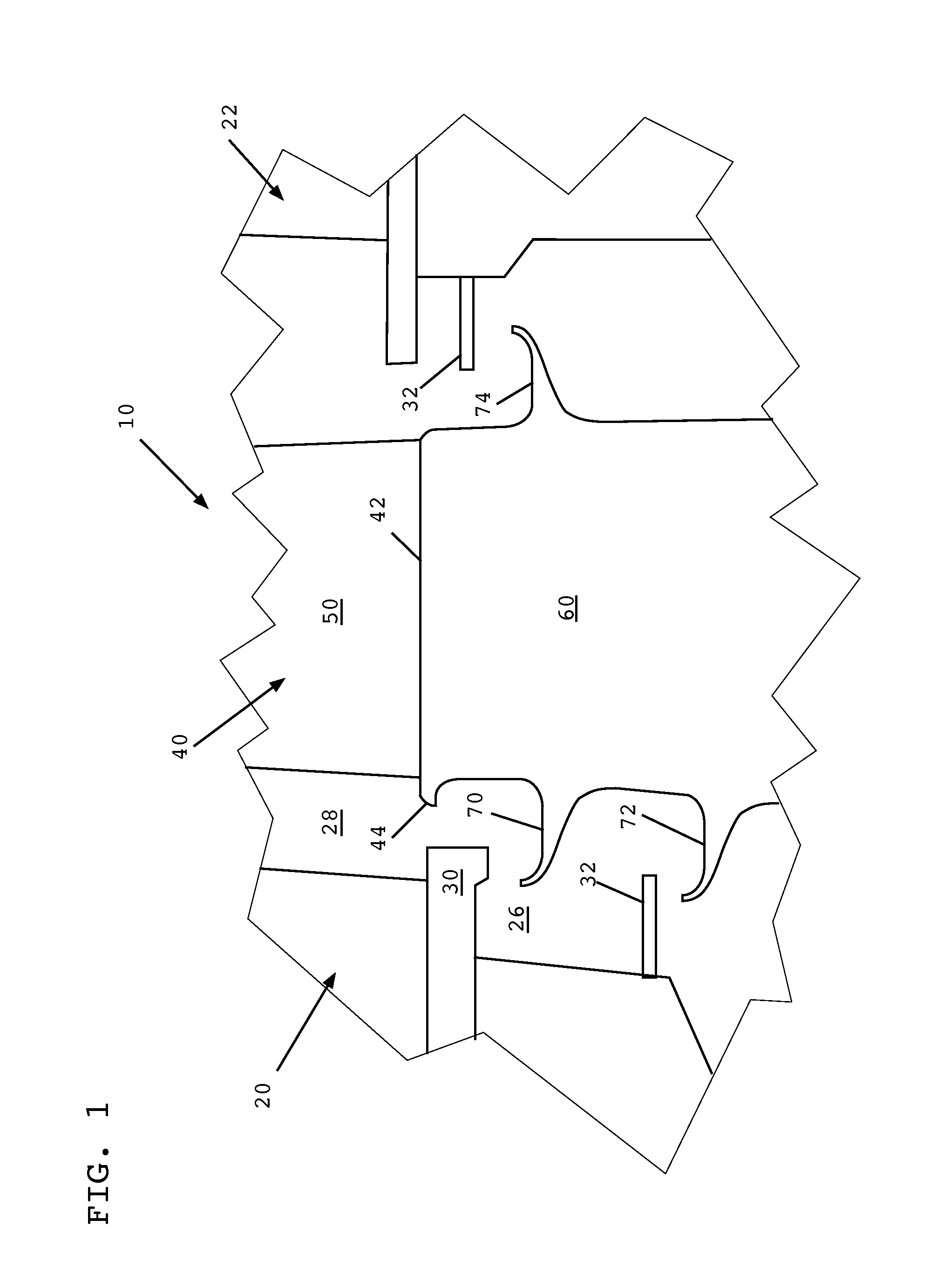

Integrated casting core-shell structure for making cast components having thin root components

The present disclosure generally relates to integrated core-shell investment casting molds that provide an indentation structure corresponding to a thin root component of the turbine blade or vane (i.e. angel wing, skirt, damper lug).

Owner:GENERAL ELECTRIC CO

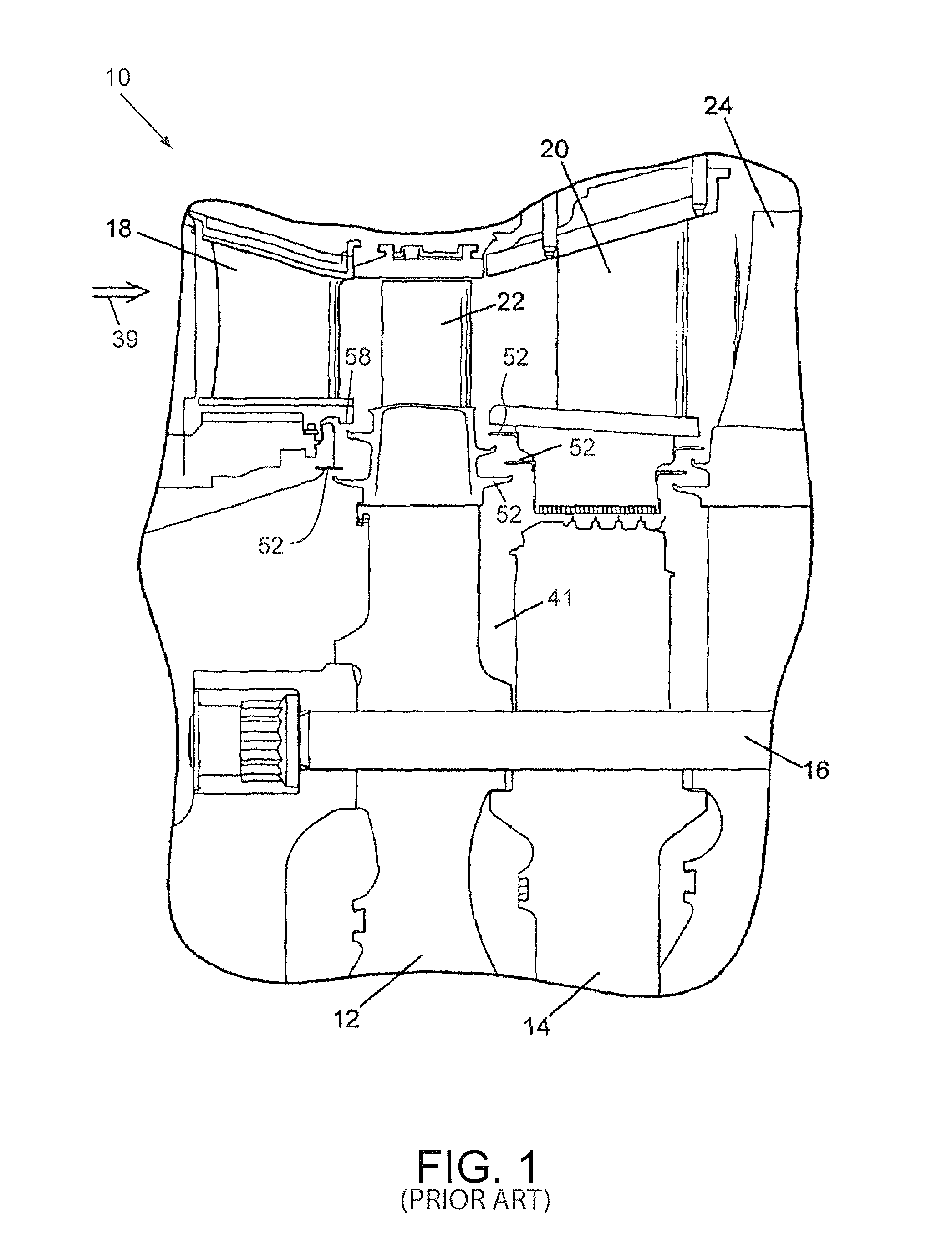

Angel wing abradable seal and sealing method

Owner:GE INFRASTRUCTURE TECH INT LLC

Angel wing abradable seal and sealing method

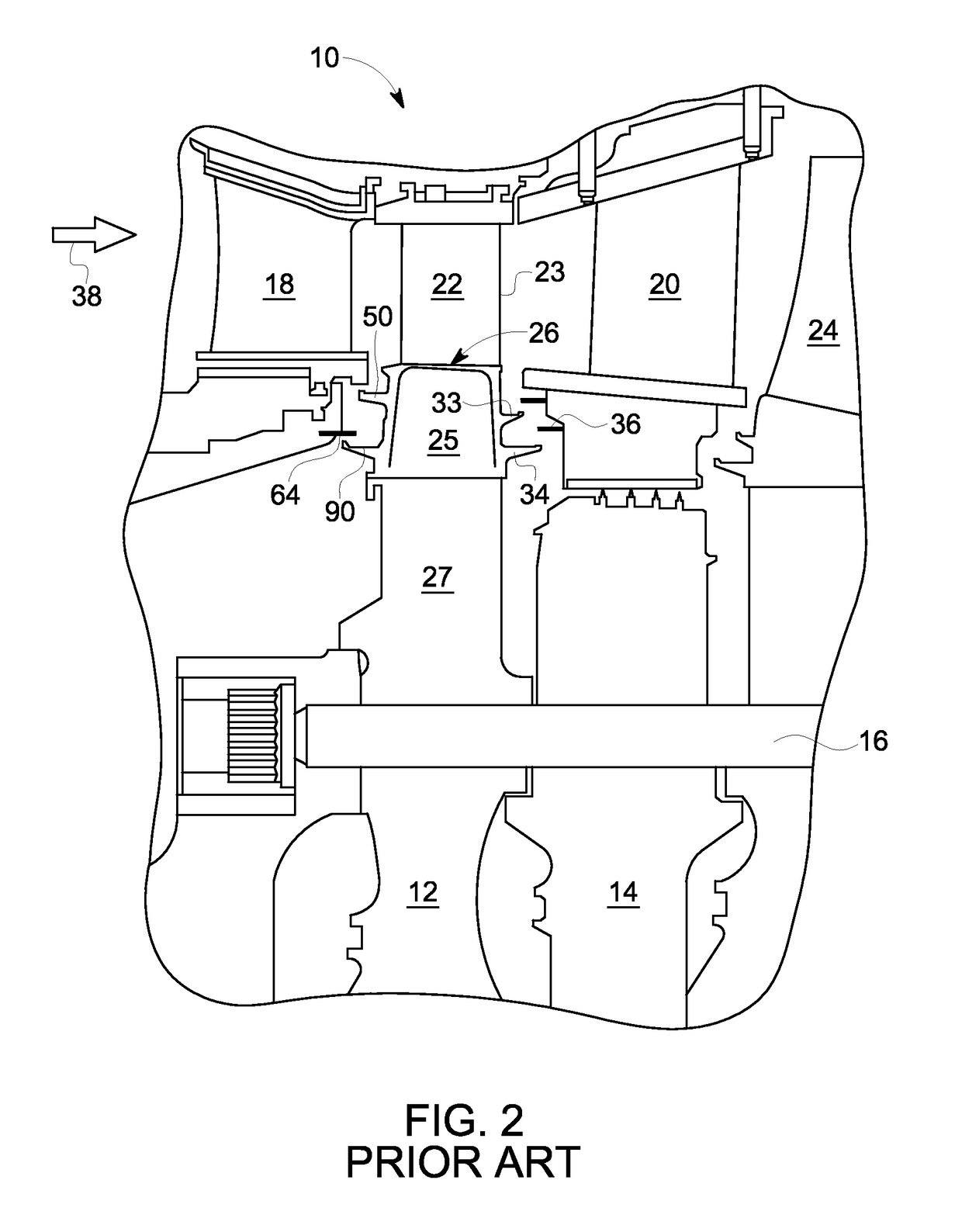

An abradable seal is provided to improve turbine performance by physically reducing the clearance between a flange portion of the nozzle and an opposed angel wing / seal plate member of the bucket. The provision of an abradable seal also mitigates angel wing / seal plate tooth or fin wear by providing for abradable contact without metal to metal hard rub.

Owner:GENERAL ELECTRIC CO

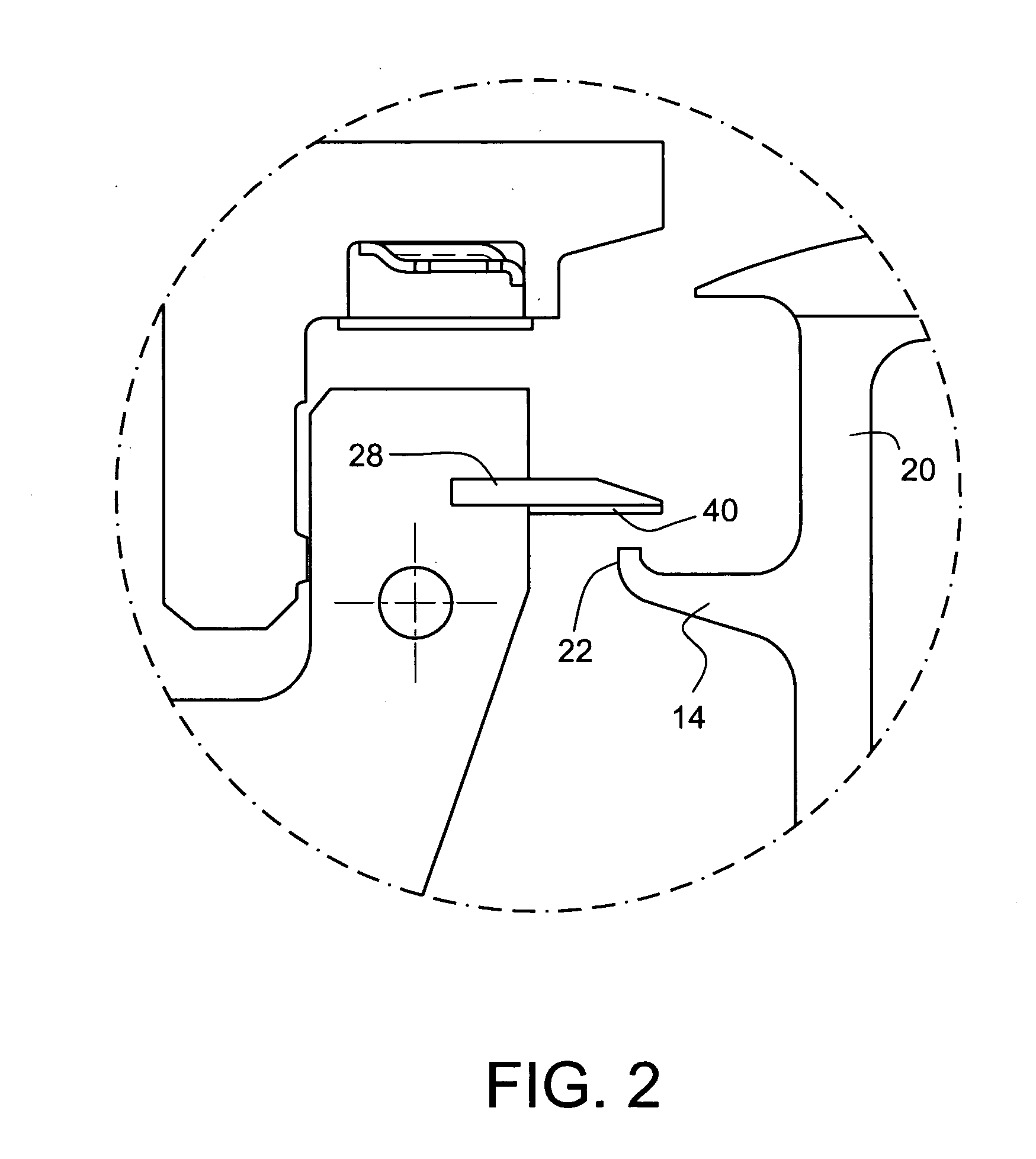

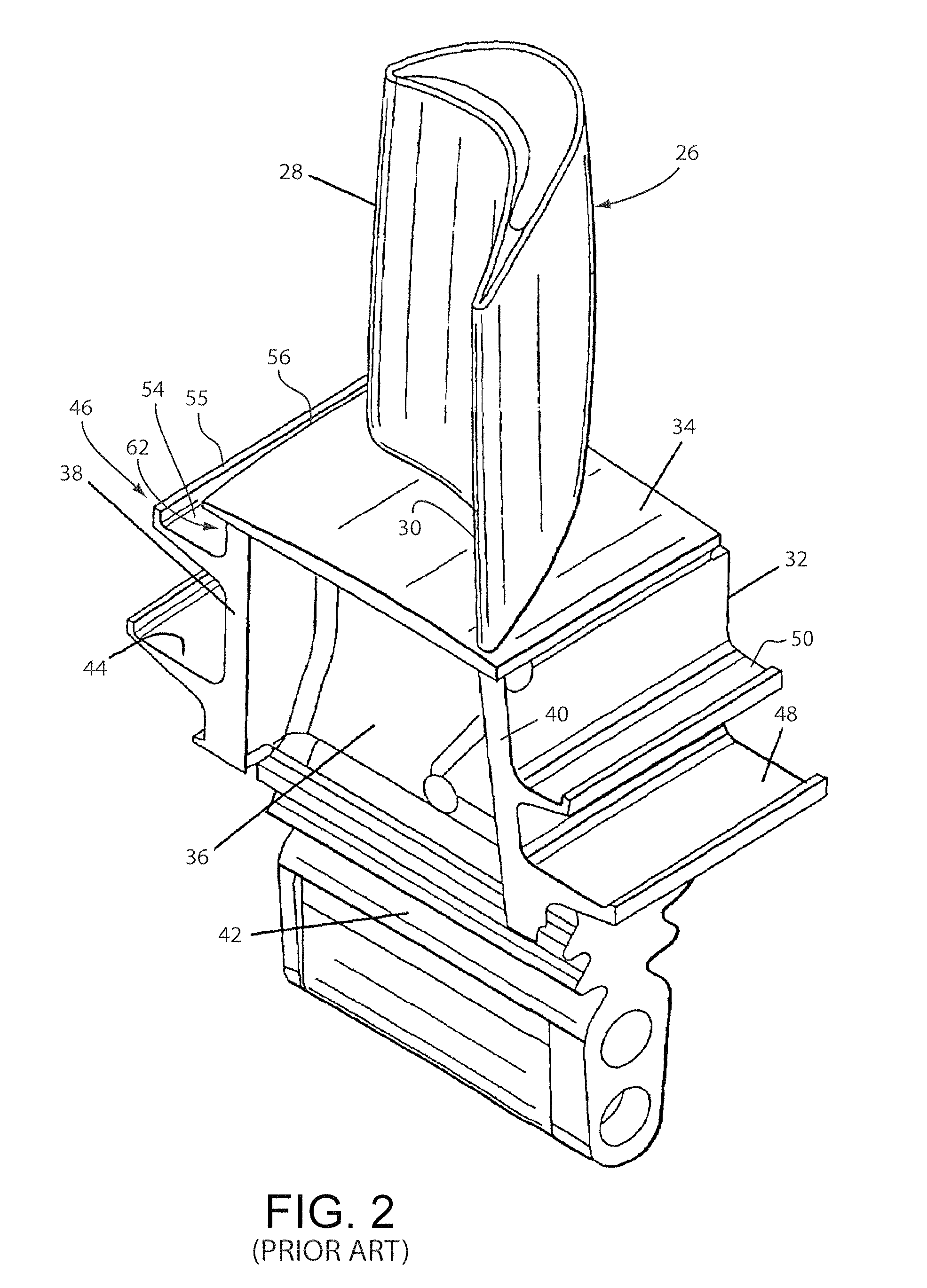

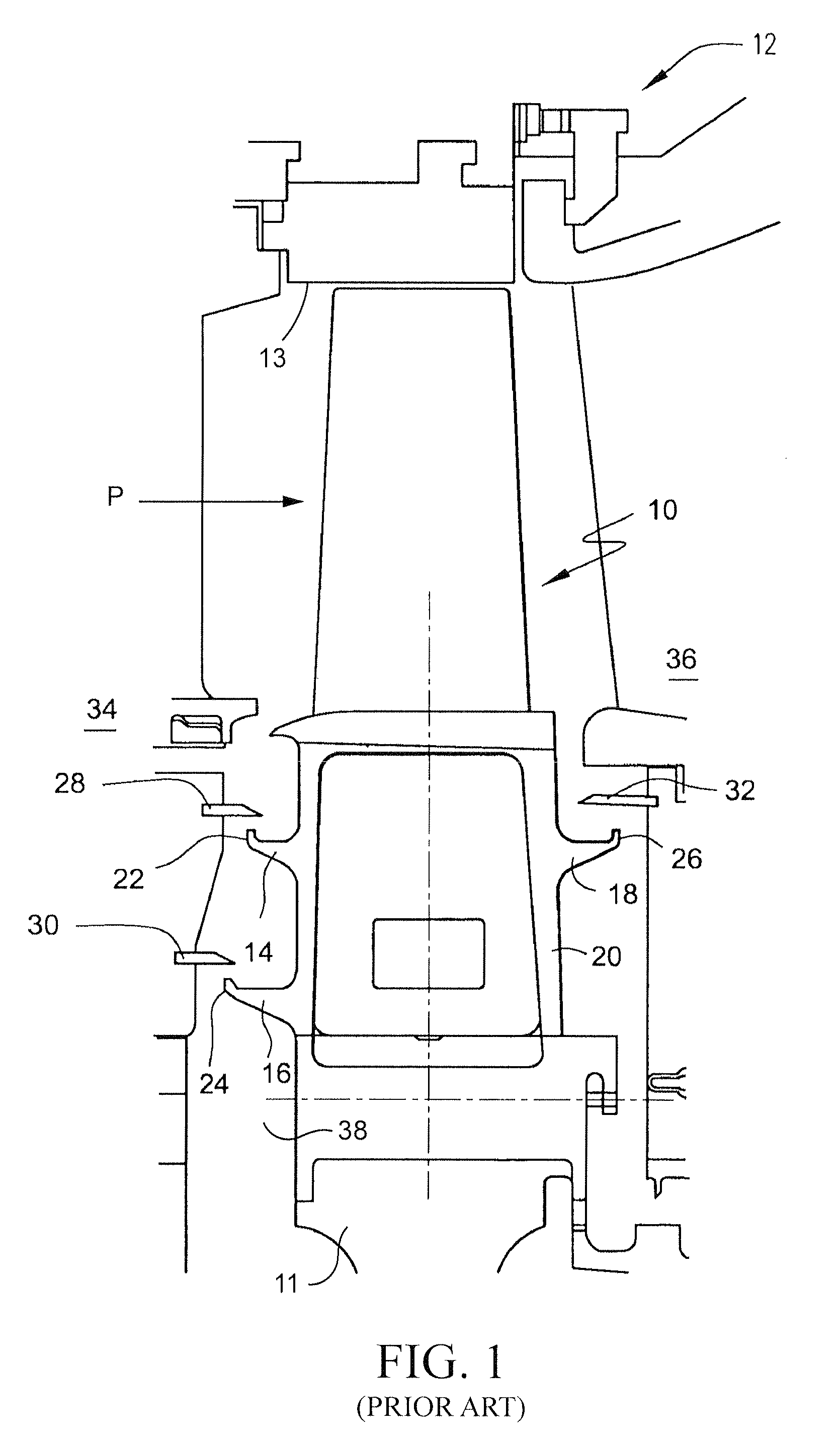

Turbine bucket angel wing compression seal

ActiveUS8083475B2Reducing turbine bucket cooling air lossesPropellersEngine manufactureTooth positionAngel wing

The present application provides an angel wing seal for a turbine bucket. The angel wing seal may include a first wing with a sinusoidally-shaped outer edge and a number of wing teeth positioned thereon.

Owner:GENERAL ELECTRIC CO

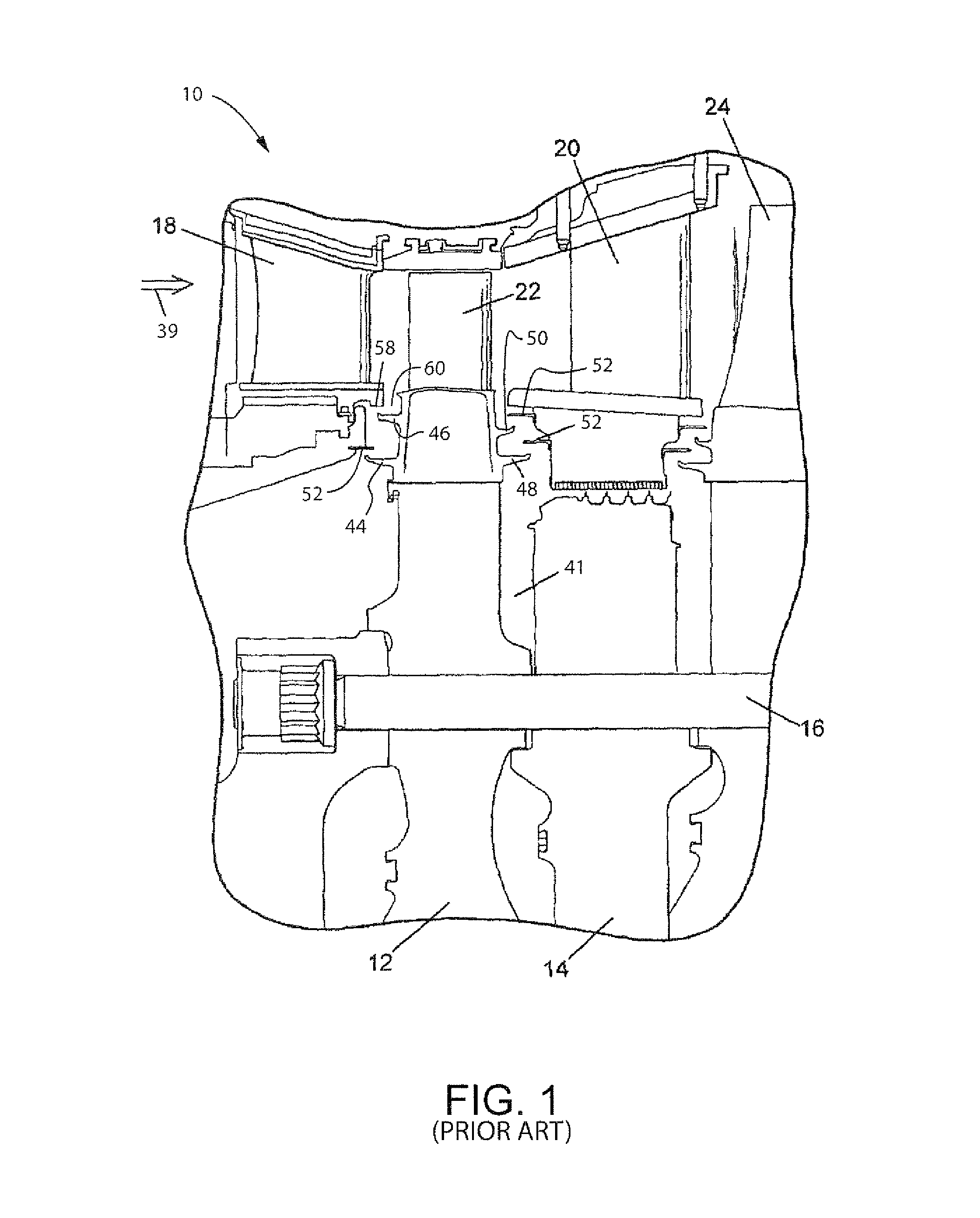

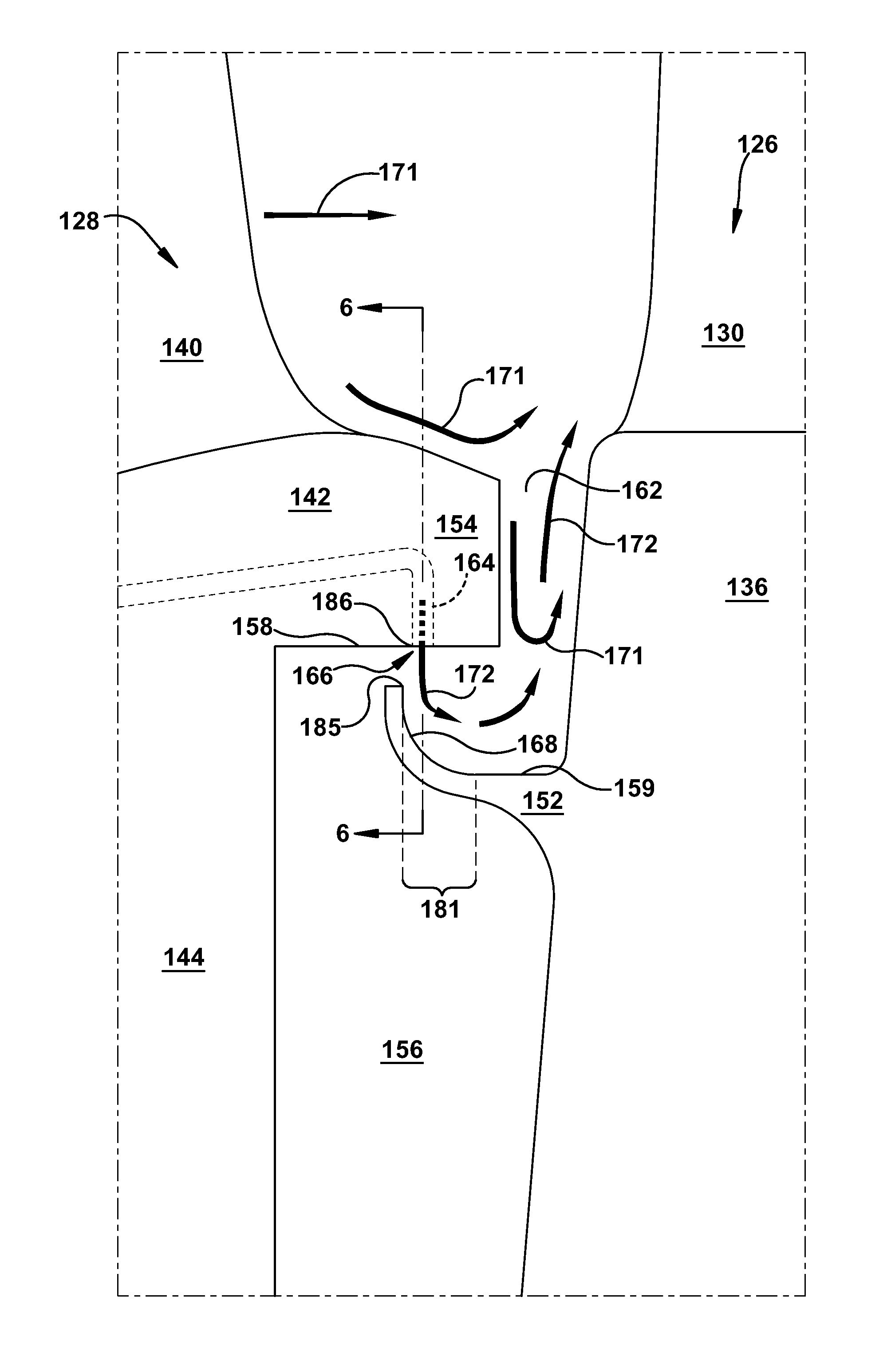

Systems and apparatus relating to seals for turbine engines

A seal in a turbine of a combustion turbine engine is described. The seal is formed within a trench cavity defined between a rotor blade and a stator blade. The stator blade includes a sidewall projection and the rotor blade includes an angel wing projection extending toward the stator blade. The side wall projection overhangs the angel wing projection. The seal include: a port disposed on an inboard surface of the stator projection; and deflecting structure disposed on the angel wing projection. The deflecting structure may be configured to receive the fluid expelled from the port and deflect the fluid toward an inlet of the trench cavity.

Owner:GENERAL ELECTRIC CO

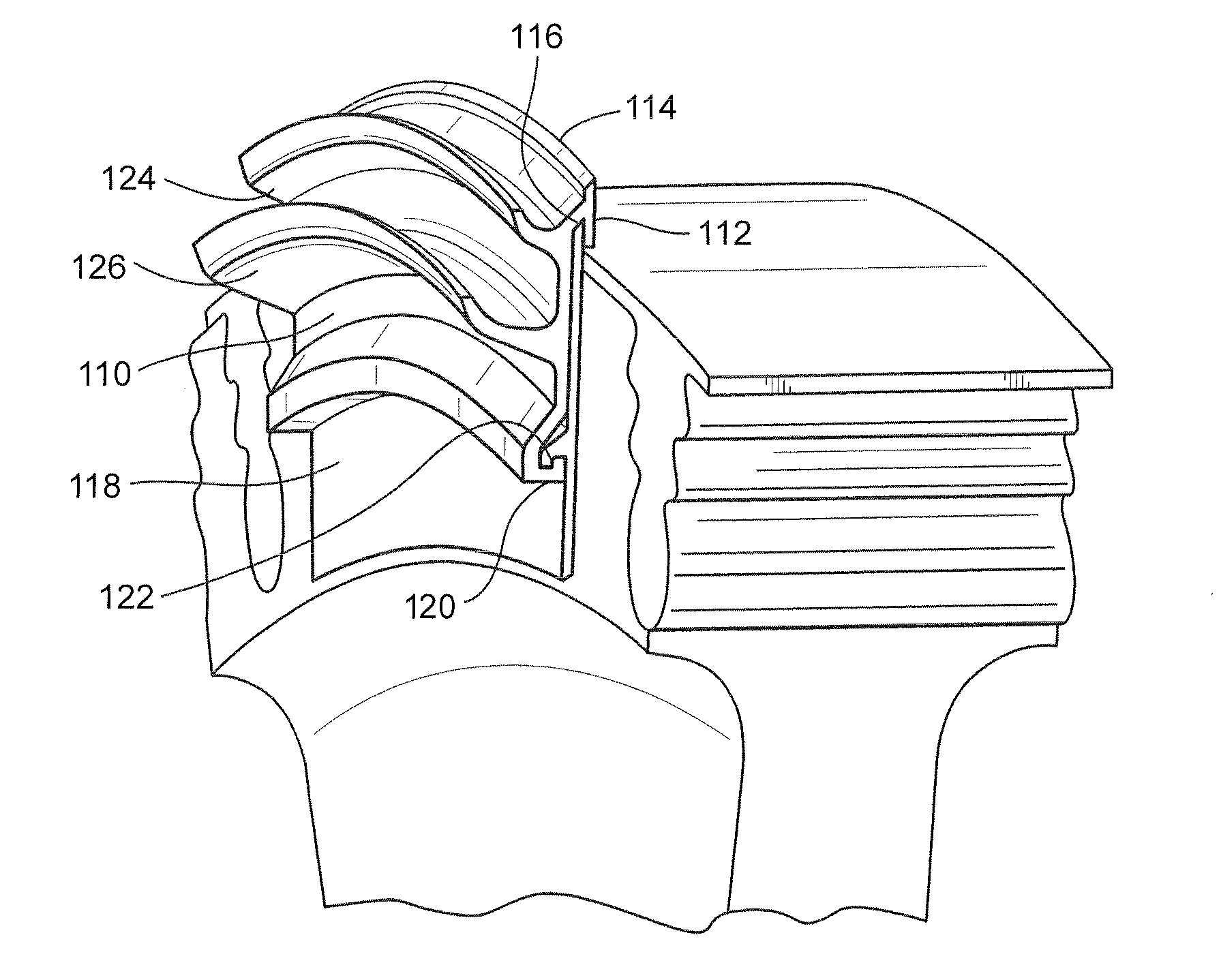

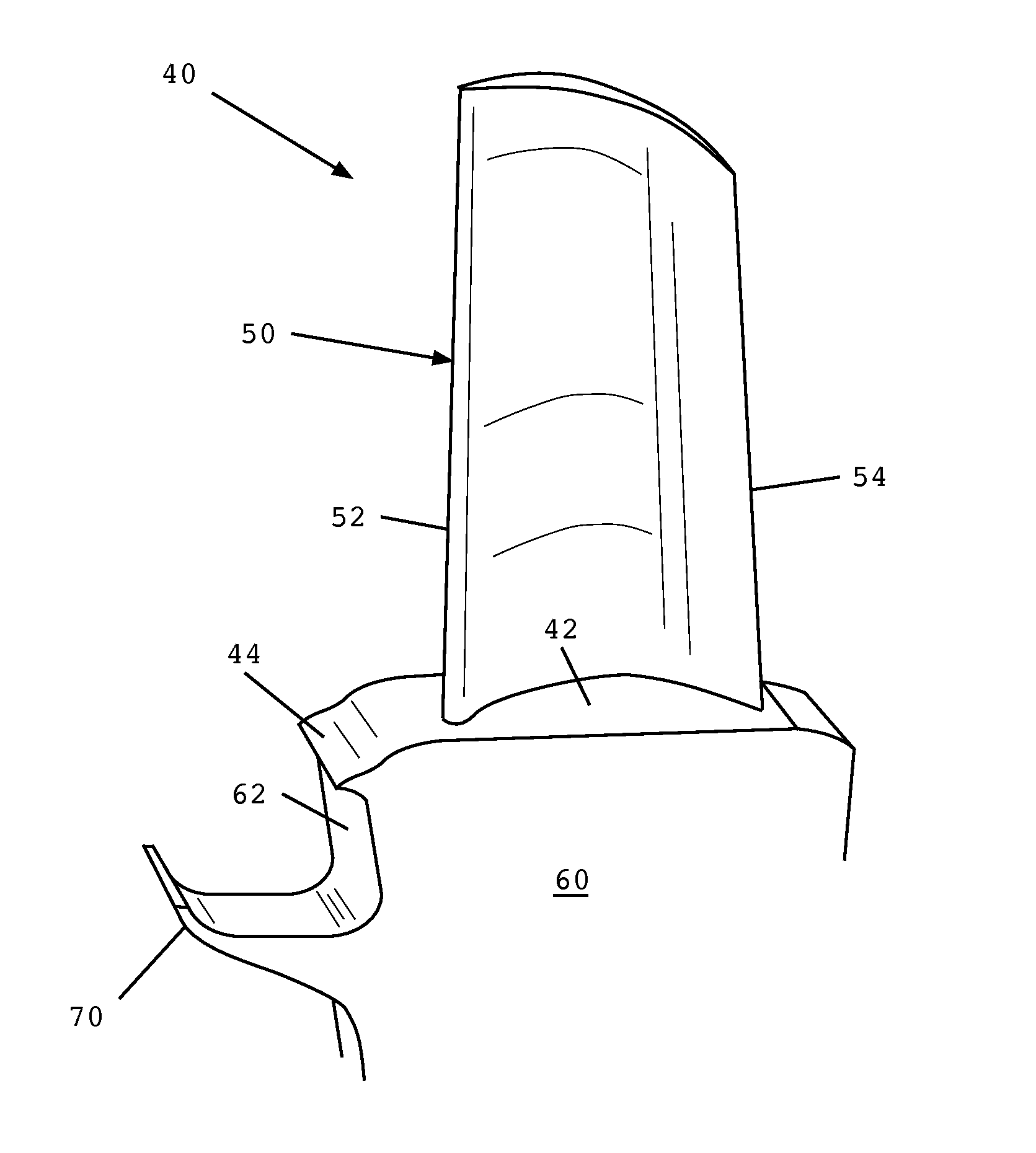

Rotating airfoil component of a turbomachine

ActiveUS20130115096A1High operating temperatureReduced cooling air flowPropellersRotary propellersWorking fluidCoating system

A rotating airfoil component equipped with one or more angel wings that inhibit the ingress of a hot working fluid into interior regions of a turbomachine in which the component is installed. The component includes an airfoil and a feature for mounting the component to enable rotation of the component within the turbomachine. An angel wing projects from the component to have a first surface facing the airfoil, an oppositely-disposed second surface facing the mounting feature, and at least one lateral surface therebetween. A thermal-insulating coating system is present on the first surface to inhibit heat transfer from the working fluid to the angel wing but not on the second or lateral surfaces so as not to inhibit heat transfer from the second and lateral surfaces of the angel wing.

Owner:GENERAL ELECTRIC CO

Non-integral segmented angel-wing seal

A cover plate adapted to axially overlie root or shank portions of one or more buckets or blades secured to a turbomachine wheel, includes an arcuate cover plate body adapted to be secured to the turbomachine wheel so as to cover a root portion of at least one of the turbine buckets or blades; and at least one arcuate angel-wing seal segment detachably secured to one side of the arcuate cover plate body.

Owner:GENERAL ELECTRIC CO

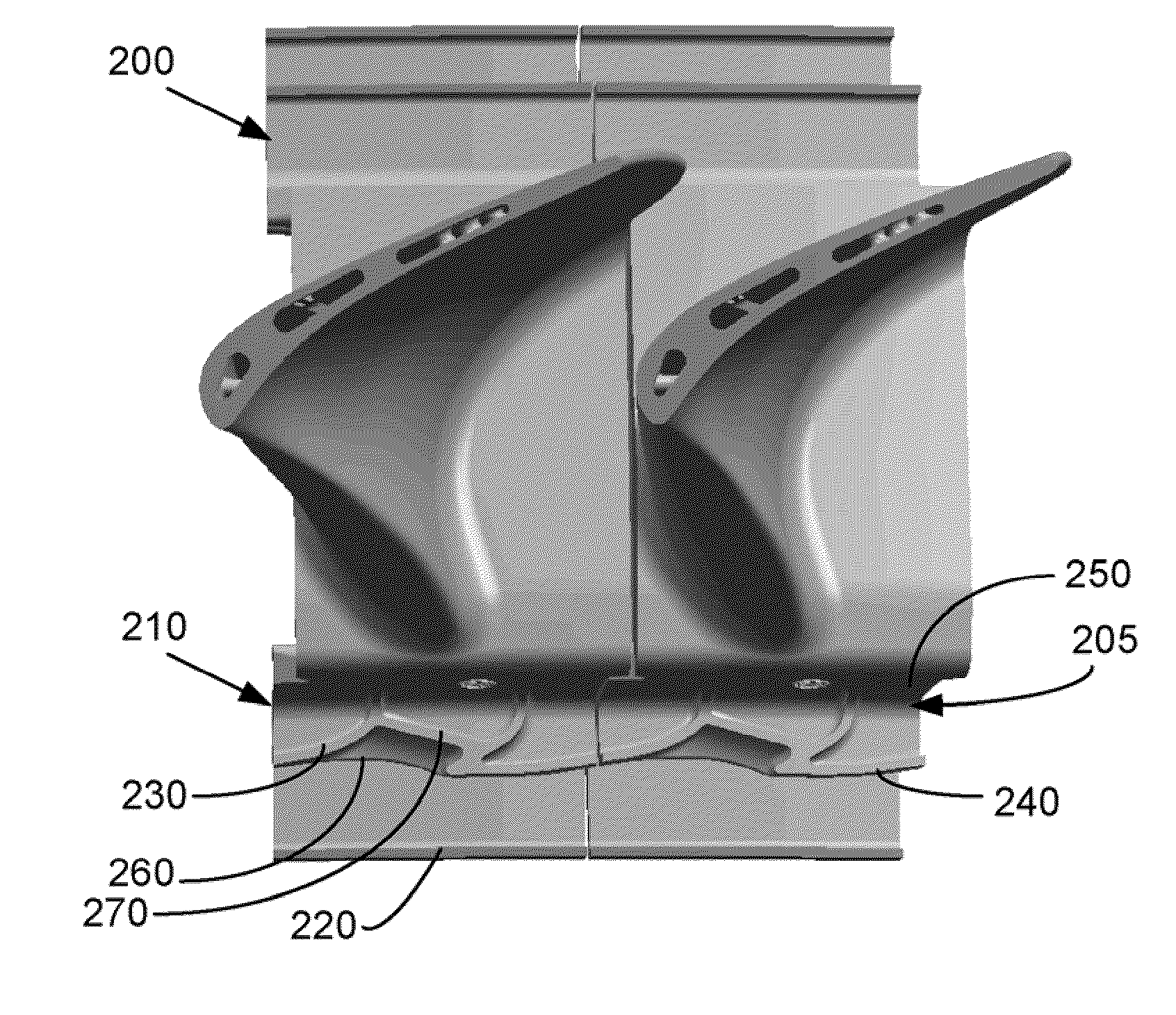

Turbine bucket angel wing features for forward cavity flow control and related method

A turbine bucket includes a radially inner mounting portion, a shank radially outward of the mounting portion, a radially outer airfoil and a substantially planar platform radially between the shank, and the airfoil. At least one axially-extending angel wing seal flange is formed on a leading end of the shank forming a circumferentially extending trench cavity along the leading edge of the shank, radially between an underside of the platform leading edge and the angel wing seal flange. A plurality of substantially radially-extending purge air holes are formed in the angel wing seal flange, adapted to fluidly connect a turbine rotor wheel space cavity with the trench cavity and thereby supply purge air to the outer surface of the angel wing seal flange.

Owner:GENERAL ELECTRIC CO

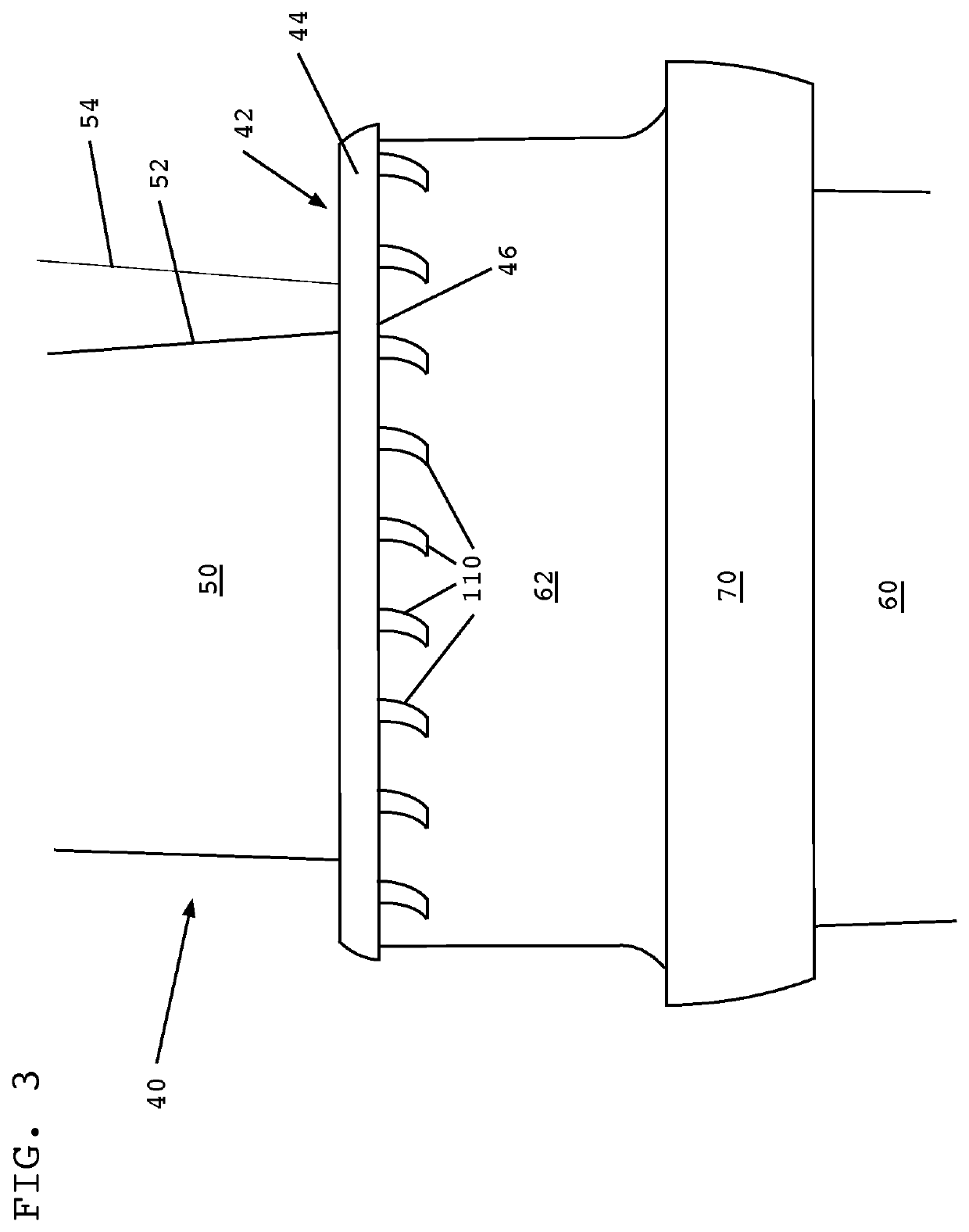

Turbine blade angel wing with pumping features

A gas turbine engine, including: a plurality of blades (60) assembled into an annular row of blades and partly defining a hot gas path (26) and a cooling fluid path (24), wherein the cooling fluid path extends from a rotor cavity (22) to the hot gas path; an angel wing assembly (99) disposed on a side (74) of a base (76) of the row of blades; and pumping features (130) distributed about the angel wing assembly configured to impart, at a narrowest gap (42) of the cooling fluid path, motion to a flow of cooling fluid flowing there through. The plurality of pumping features, the angel wing assembly, and the base of the row of blades are effective to produce a helical motion to the flow of cooling fluid as it enters the hot gas path.

Owner:SIEMENS AG

Turbine bucket angel wing features for forward cavity flow control and related method

A turbine bucket includes a radially inner mounting portion, a shank radially outward of the mounting portion, a radially outer airfoil and a substantially planar platform radially between the shank and the airfoil. At least one axially-extending angel wing seal flange is formed on a leading end of the shank thus forming a circumferentially extending trench cavity along the leading end of the shank, radially between an underside of the platform leading edge and the angel wing seal flange. A plurality of substantially radially grooves are formed on a radially outer surface of the angel wing seal flange and extend into the shank.

Owner:GENERAL ELECTRIC CO

Non-integral segmented angel-wing seal

A cover plate adapted to axially overlie root or shank portions of one or more buckets or blades secured to a turbomachine wheel, includes an arcuate cover plate body adapted to be secured to the turbomachine wheel so as to cover a root portion of at least one of the turbine buckets or blades; and at least one arcuate angel-wing seal segment detachably secured to one side of the arcuate cover plate body.

Owner:GE INFRASTRUCTURE TECH INT LLC

Turbine bucket angel wing features for forward cavity flow control and related method

A turbine bucket includes a radially inner mounting portion, a shank radially outward of the mounting portion, a radially outer airfoil and a substantially planar platform radially between the shank and the airfoil. At least one axially-extending angel wing seal flange is formed on a leading end of the shank thus forming a circumferentially extending trench cavity along the leading end of the shank, radially between an underside of the platform leading edge and the angel wing seal flange. A plurality of substantially radially grooves are formed on a radially outer surface of the angel wing seal flange and extend into the shank.

Owner:GE INFRASTRUCTURE TECH INT LLC

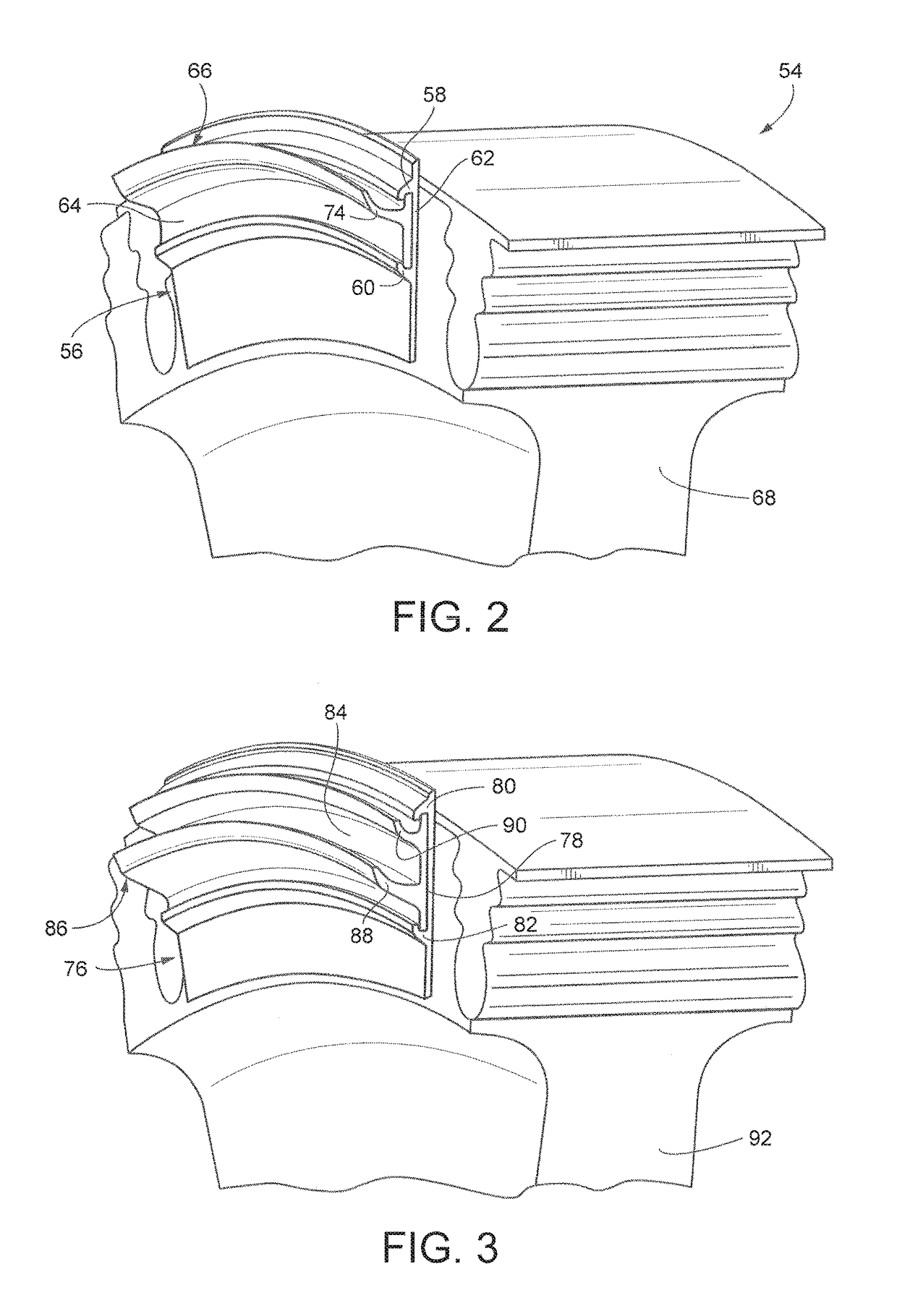

Aft outer rim seal arrangement

An outer rim seal arrangement (10), including: an annular rim (70) centered about a longitudinal axis (30) of a rotor disc (31), extending fore and having a fore-end (72), an outward-facing surface (74), and an inward-facing surface (76); a lower angel wing (62) extending aft from a base of a turbine blade (22) and having an aft end (64) disposed radially inward of the rim inward-facing surface to define a lower angel wing seal gap (80); an upper angel wing (66) extending aft from the turbine blade base and having an aft end (68) disposed radially outward of the rim outward-facing surface to define a upper angel wing seal gap (80, 82); and guide vanes (100) disposed on the rim inward-facing surface in the lower angel wing seal gap. Pumping fins (102) may be disposed on the upper angel wing seal aft end in the upper angel wing seal gap.

Owner:SIEMENS ENERGY INC

Honeycomb construction for abradable angel wing

InactiveUS20130139386A1Improve sealingLess riskEngine manufactureMetal rolling stand detailsSpray nozzleHoneycomb structure

An abradable honeycomb is integrally formed in a turbine nozzle sealing flange for engagement with a bucket angel wing to reduce the leakage of air into the turbine's hot gas path. The honeycomb is integrally formed in a turbine nozzle sealing flange using a sinker EDM method to directly sink the honeycomb into the sealing flange itself, so that the honeycomb is an integral part of the flange. For repair, an entirely new honeycomb flange can be made and welded or brazed on to the turbine nozzle.

Owner:GENERAL ELECTRIC CO

Turbine bucket cooling

Embodiments of the invention relate generally to rotary machines and, more particularly, to the cooling of at least portions of a turbine bucket. In one embodiment, the invention provides a method of cooling at least a portion of a turbine bucket, the method comprising: during operation of a turbine, altering a swirl velocity of purge air beneath a platform lip extending axially from the platform, wherein altering the swirl velocity of the purge air includes interrupting a flow of the purge air with a plurality of voids disposed along a length of an angel wing extending axially from a face of a shank portion of the turbine bucket.

Owner:GENERAL ELECTRIC CO

Turbine Bucket Angel Wing Compression Seal

ActiveUS20100178159A1Reducing turbine bucket cooling air lossReducing turbine bucket cooling air lossesPropellersEngine manufactureTurbine bladeTooth position

The present application provides an angel wing seal for a turbine bucket. The angel wing seal may include a first wing with a sinusoidally-shaped outer edge and a number of wing teeth positioned thereon.

Owner:GENERAL ELECTRIC CO

Turbine blade angel wing with pumping features

A gas turbine engine, including: a plurality of blades (60) assembled into an annular row of blades and partly defining a hot gas path (26) and a cooling fluid path (24), wherein the cooling fluid path extends from a rotor cavity (22) to the hot gas path; an angel wing assembly (99) disposed on a side (74) of a base (76) of the row of blades; and pumping features (130) distributed about the angel wing assembly configured to impart, at a narrowest gap (42) of the cooling fluid path, motion to a flow of cooling fluid flowing there through. The plurality of pumping features, the angel wing assembly, and the base of the row of blades are effective to produce a helical motion to the flow of cooling fluid as it enters the hot gas path.

Owner:SIEMENS AG

Turbine bucket platform shaping for gas temperature control and related method

A turbine bucket includes a radially inner mounting portion; a shank radially outward of the mounting portion; at least one radially outer airfoil having a leading edge and a trailing edge; a substantially planar platform radially between the shank and the at least one radially outer airfoil; at least one axially-extending angel wing seal flange on a leading end of the shank thus forming a circumferentially extending trench cavity along the leading end of the shank, radially between an underside of the platform leading edge and a radially outer side of the angel wing seal flange; and slash faces along opposite, circumferentially-spaced side edges of the platform. At least one of the slash faces is formed with a dog-leg shape, a leading end of the at least one of slash face terminating at a location circumferentially offset from the leading edge of the at least one radially outer airfoil.

Owner:GENERAL ELECTRIC CO

Gas turbine seal arrangement

A turbine arrangement including a rotor and a stator surrounding the rotor and comprising guide vane segments, each guide vane segment comprising an airfoil and a radially inner vane platform. A seal arrangement includes a static seal inward from the inner vane platforms and having a radially extending face plate, first and second cylindrical seal walls extending from outer and inner ends of the annular face plate, an annular seal plate extending radially from the second cylindrical seal wall, and an angel wing extending between the first cylindrical seal wall and the annular seal plate to define a first annular cavity and a second annular cavity. Circumferentially spaced cut-outs define passages through the annular seal plate between the first and second annular cavities and are aligned with fasteners that attach the annular face plate to a support ring for supporting the inner vane platform.

Owner:SIEMENS ENERGY INC

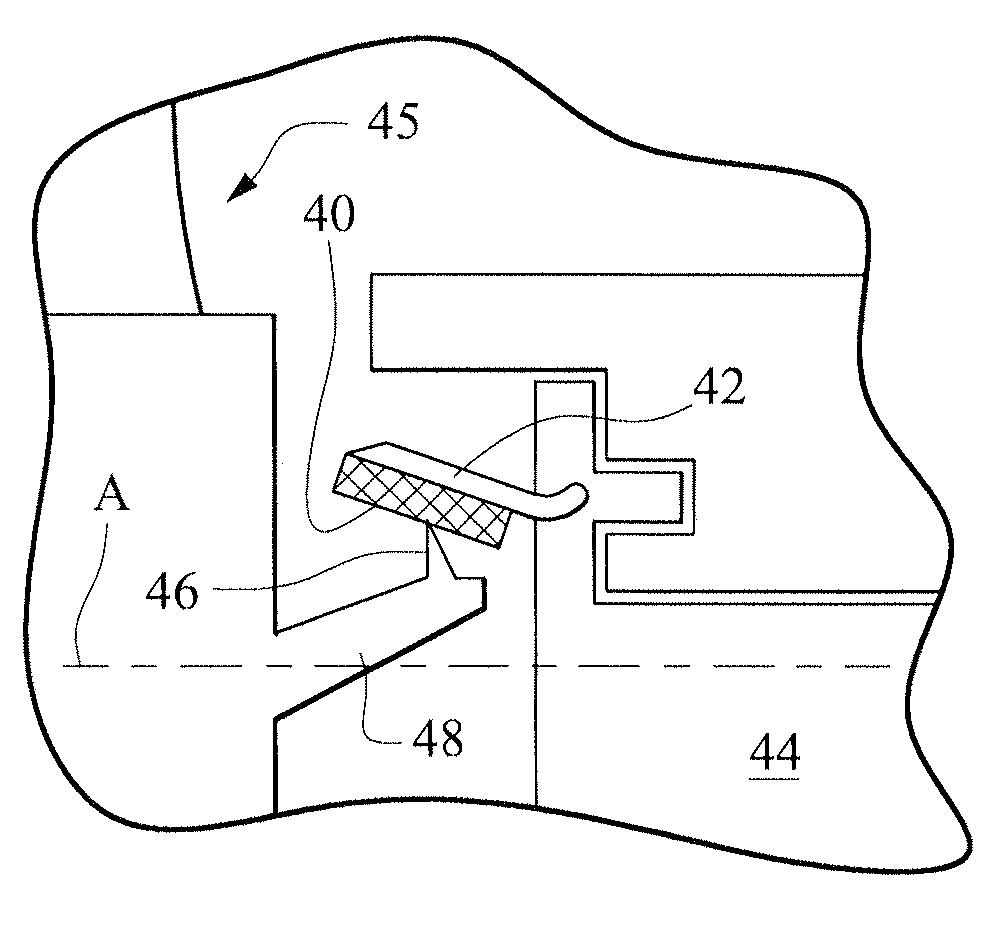

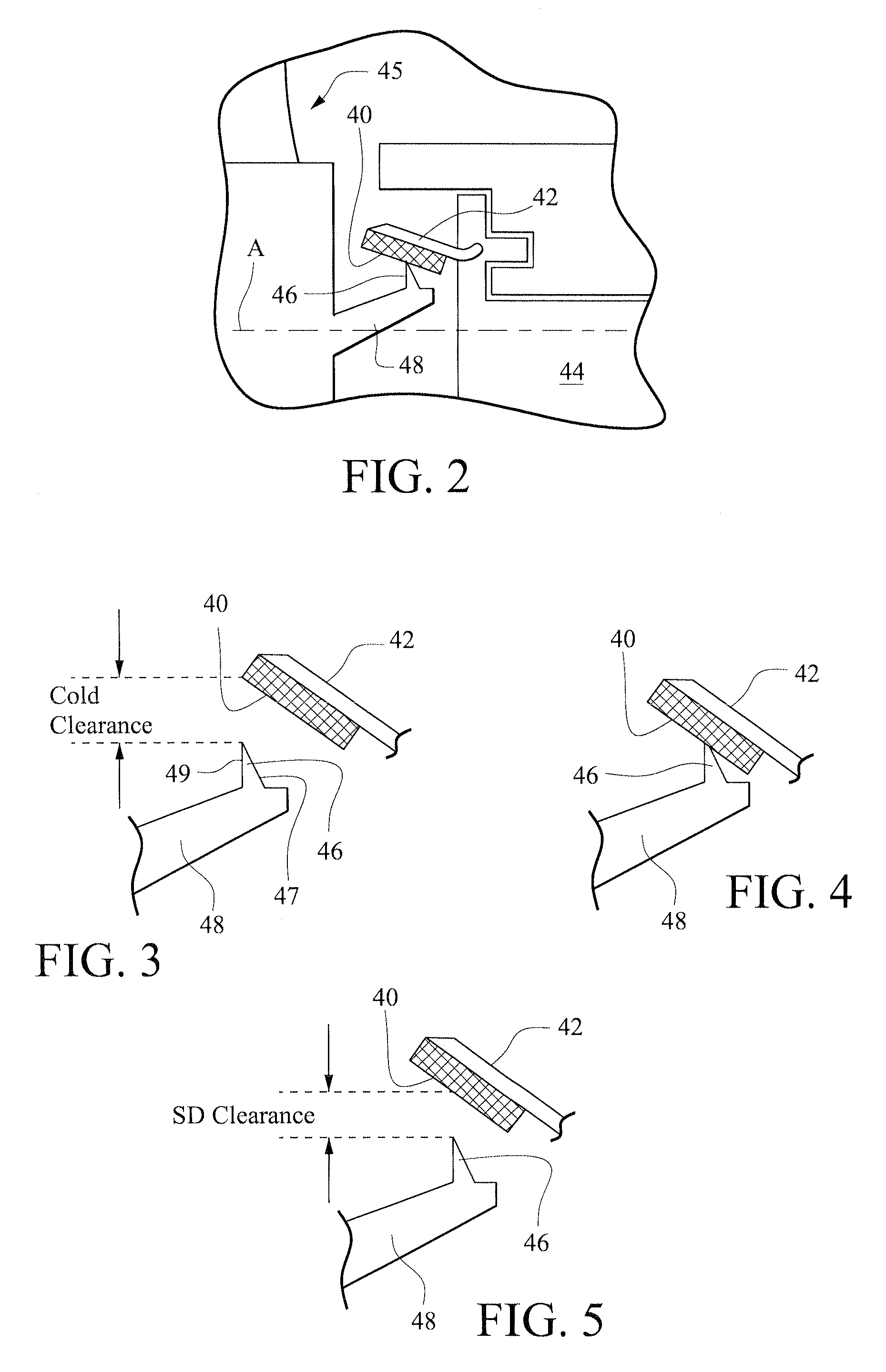

Retrofittable interstage angled seal

InactiveUS9145788B2Reduce seal gapReduce radial sizeEngine manufacturePump componentsCircular discAcute angle

A rotary turbomachine includes a rotor mounting at least one disk having an outer surface and at least one bucket extending radially from said outer surface. A stationary stator component is located adjacent the disk, and a seal plate extends from a portion of the stationary stator component. An angel wing seal extends from the bucket, thereby defining a clearance gap between the seal plate and the angel wing seal. An abradable seal element is disposed on the seal plate, and the abradable seal element and the seal plate are canted at an acute angle relative to a center axis of the rotor extending radially outwardly in a direction toward the angel wing seal.

Owner:GENERAL ELECTRIC CO

Turbine bucket platform shaping for gas temperature control and related method

A turbine bucket includes a radially inner mounting portion; a shank radially outward of the mounting portion; at least one radially outer airfoil having a leading edge and a trailing edge; a substantially planar platform radially between the shank and the at least one radially outer airfoil; at least one axially-extending angel wing seal flange on a leading end of the shank thus forming a circumferentially extending trench cavity along the leading end of the shank, radially between an underside of the platform leading edge and a radially outer side of the angel wing seal flange; and slash faces along opposite, circumferentially-spaced side edges of the platform. At least one of the slash faces is formed with a dog-leg shape, a leading end of the at least one of slash face terminating at a location circumferentially offset from the leading edge of the at least one radially outer airfoil.

Owner:GENERAL ELECTRIC CO

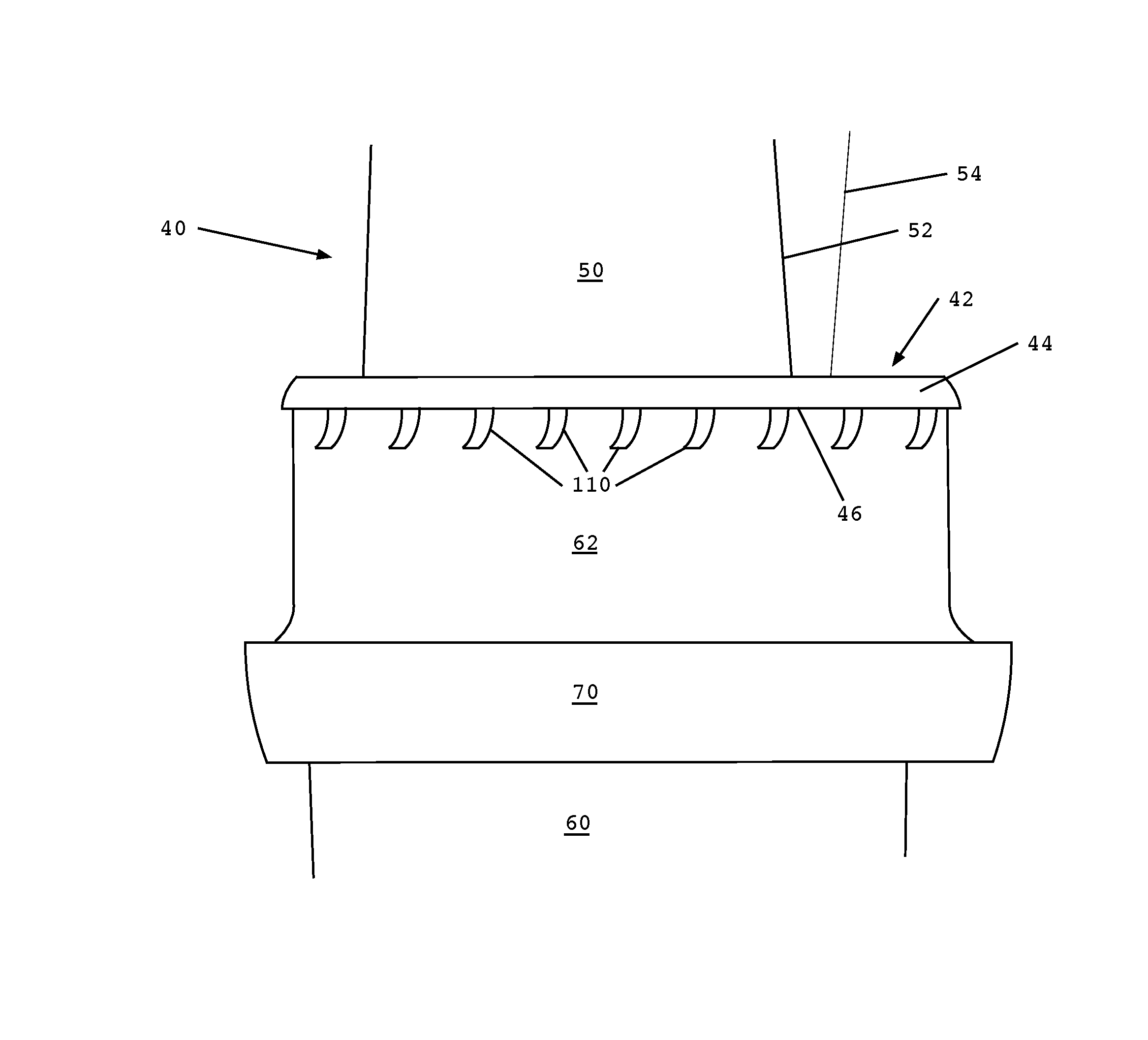

Turbine bucket for control of wheelspace purge air

Embodiments of the invention relate generally to rotary machines and, more particularly, to the control of wheel space purge flow in gas turbines. In one embodiment, the invention provides a turbine bucket comprising: a platform portion; an airfoil extending radially outward from the platform portion; a shank portion extending radially inward from the platform portion; at least one angel wing extending axially from a face of the shank portion; a platform lip extending axially from the platform portion, the platform lip disposed radially outward from the at least one angel wing; and a plurality of turbulators disposed along and extending outward from the face of the shank portion between the platform lip and the at least one angel wing.

Owner:GENERAL ELECTRIC CO

Turbine bucket for control of wheelspace purge air

Embodiments of the invention relate generally to rotary machines and, more particularly, to the control of wheel space purge air in gas turbines. In one embodiment, the invention provides a turbine bucket comprising: a platform portion; an airfoil extending radially outward from the platform portion; a shank portion extending radially inward from the platform portion; at least one angel wing extending axially from a face of the shank portion, the at least one angel wing including an angel wing rim extending radially upward toward the airfoil; and a plurality of voids disposed along the angel wing rim.

Owner:GENERAL ELECTRIC CO

Turbine bucket for control of wheelspace purge air

Embodiments of the invention relate generally to rotary machines and, more particularly, to the control of wheel space purge air in gas turbines. In one embodiment, the invention provides a turbine bucket comprising: a platform portion; an airfoil extending radially outward from the platform portion; a shank portion extending radially inward from the platform portion; an angel wing extending axially from a face of the shank portion; and a plurality of voids disposed along a length of the angel wing, each of the plurality of voids extending radially through the angel wing.

Owner:GENERAL ELECTRIC CO

Aft outer rim seal arrangement

An outer rim seal arrangement (10), including: an annular rim (70) centered about a longitudinal axis (30) of a rotor disc (31), extending fore and having a fore-end (72), an outward-facing surface (74), and an inward-facing surface (76); a lower angel wing (62) extending aft from a base of a turbine blade (22) and having an aft end (64) disposed radially inward of the rim inward-facing surface to define a lower angel wing seal gap (80); an upper angel wing (66) extending aft from the turbine blade base and having an aft end (68) disposed radially outward of the rim outward-facing surface to define a upper angel wing seal gap (80, 82); and guide vanes (100) disposed on the rim inward-facing surface in the lower angel wing seal gap. Pumping fins (102) may be disposed on the upper angel wing seal aft end in the upper angel wing seal gap.

Owner:SIEMENS ENERGY INC

Turbine blades having shank features and methods of fabricating the same

A method of modifying a shank of a turbine blade from an initial profile to an undercut profile includes removing a first portion of material from an underside of a downstream angel wing of the turbine blade. The downstream angel wing extends axially from a downstream cover plate of the shank. The method also includes removing a second portion of material from a generally axially-extending portion of the downstream cover plate adjacent a dovetail of the turbine blade.

Owner:GENERAL ELECTRIC CO

Stator rim for a turbine engine

ActiveUS20170198585A1Minimize hot gas ingestionBlade accessoriesEfficient propulsion technologiesGas turbinesAngel wing

A stator rim structure for a gas turbine engine comprises a stator having an end wall and a discourager defining a channel therebetween. The end wall is adjacent to a hot gas flow and the discourager is adjacent to a purge flow. A rotor has an angel wing extending into the channel. At least one supply passage is disposed within the stator and extends through the discourager and at least one aperture fluidly couples the supply passage with the channel. A flow of cooling air is fed from the supply passage into the aperture and into the channel to form a fluidic dam discouraging ingestion of the hot gas flow.

Owner:GENERAL ELECTRIC CO

Systems and apparatus relating to seals for turbine engines

A seal in a turbine of a combustion turbine engine is described. The seal is formed within a trench cavity defined between a rotor blade and a stator blade. The stator blade includes a sidewall projection and the rotor blade includes an angel wing projection extending toward the stator blade. The side wall projection overhangs the angel wing projection. The seal include: a port disposed on an inboard surface of the stator projection; and deflecting structure disposed on the angel wing projection. The deflecting structure may be configured to receive the fluid expelled from the port and deflect the fluid toward an inlet of the trench cavity.

Owner:GE INFRASTRUCTURE TECH INT LLC

Turbine bucket cooling

Embodiments of the invention relate generally to rotary machines and, more particularly, to the cooling of at least portions of a turbine bucket. In one embodiment, the invention provides a method of cooling at least a portion of a turbine bucket, the method comprising: during operation of a turbine, altering a swirl velocity of purge air beneath a platform lip extending axially from the platform, wherein altering the swirl velocity of the purge air includes interrupting a flow of the purge air with a plurality of voids disposed along a length of an angel wing extending axially from a face of a shank portion of the turbine bucket.

Owner:GENERAL ELECTRIC CO

Turbomachine bucket having angel wing for differently sized discouragers and related methods

Owner:GE INFRASTRUCTURE TECH INT LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com