Method for fabricating semiconductor thin film

a technology of silicon semiconductor and thin film, which is applied in the direction of semiconductor devices, coatings, transistors, etc., can solve the problems of low heat resistance, low cost, and high cost of quartz substrate, and achieve the effect of suppressing metal element deviation and facilitating the removal of silicon film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

Embodiment 1 relates to a technology of dispersing a nickel element into an amorphous silicon film from a crystalline silicon film (allowing the amorphous silicon film to such the nickel element) to lower a density of the nickel element in the crystalline silicon film as a consequence, by forming an amorphous silicon film, introducing into the amorphous silicon film a metal film which promotes the crystallization of silicon film, forming an amorphous silicon film on a crystallized silicon film (crystalline silicon film) via an oxide film (silicon oxide film), followed by performing heat treatment again.

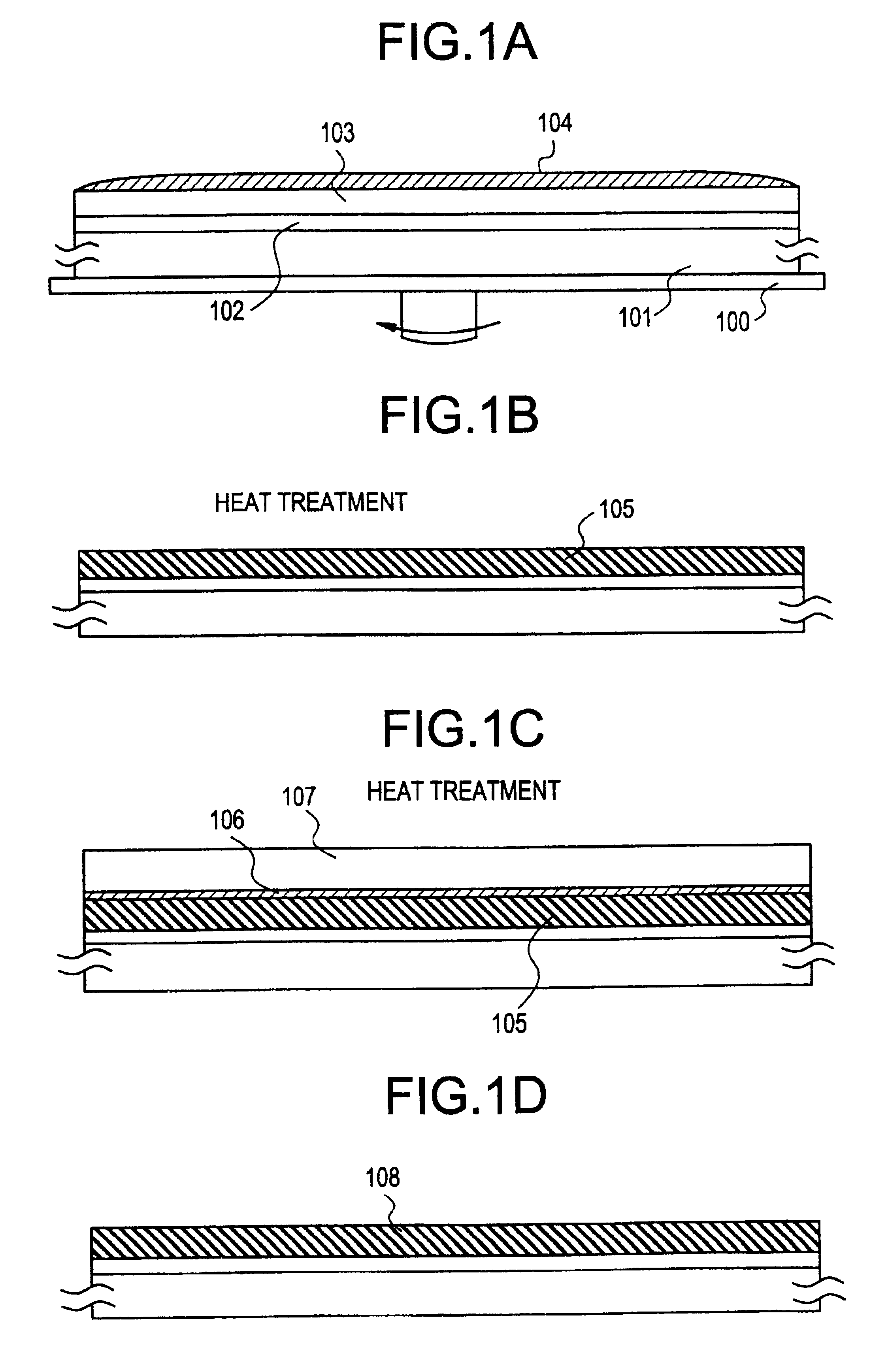

FIG. 1 shows a step of fabricating a crystalline silicon film described in this embodiment. In the beginning, on Corning 7059 glass substrate 101 (having a strain point of 593.degree. C.), a silicon oxide film 102 is formed to a thickness of 3000 .ANG. as a base film. The silicon oxide film 102 is intended to prevent impurities and alkaline ions from being dispersed into the semicondu...

embodiment 2

Embodiment 2 is characterized in that the step of heat treatment in the fabrication process in embodiment 1 is carried out by setting the conditions as follows; heating temperature is 550.degree. C., and heating duration is four hours. When the heat treatment step shown in FIG. 1(C) is carried out at 550.degree. C. for four hours, the amorphous silicon film denoted by 107 is crystallized with the action of the nickel element which is dispersed from the crystalline silicon film 105.

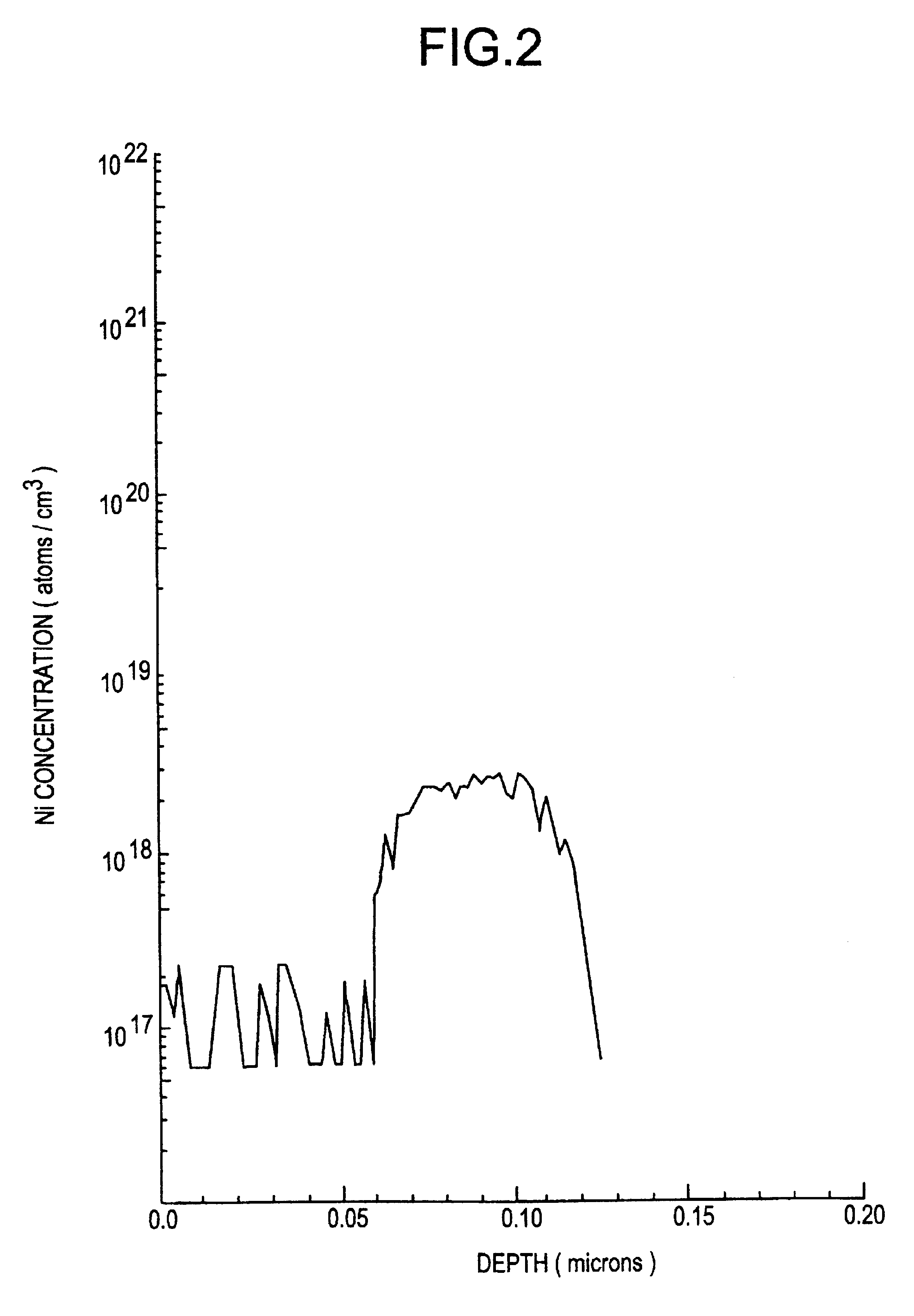

At this time, the crystalline advances in a direction of heading from the crystalline silicon film 105 to the amorphous silicon film 107 via the oxide film 106. As described above, the metal element which promotes the crystallization of silicon tends to be concentrated at the tip portion of the crystal growth. Consequently, an area where the nickel element is concentrated exist in the crystallized silicon film 107 (which is transformed into a crystalline film at this stage). Then naturally the density of n...

embodiment 3

Embodiment 3 shows an example of fabricating a thin film transistor by using the crystalline silicon film which is obtained by the method for fabricating the silicon film shown in embodiments 1 and 2. Referring to FIG, 5, there is shown a method for fabricating the thin film transistor. In the beginning, a crystalline silicon film 503 is formed on the glass substrate 501 on which a base film 502 is formed by using a method shown in embodiments 1 and 2. (FIG. 5(A)) Subsequently, the crystalline silicon film 503 thus obtained is patterned to form an active layer of the thin film transistor as shown by reference numeral 504. Then a silicon oxide film 505 is formed to a thickness of 1000 .ANG. which functions as a gate insulating film by the plasma CVD and the low pressure thermal CVD. (FIG. 5(B))

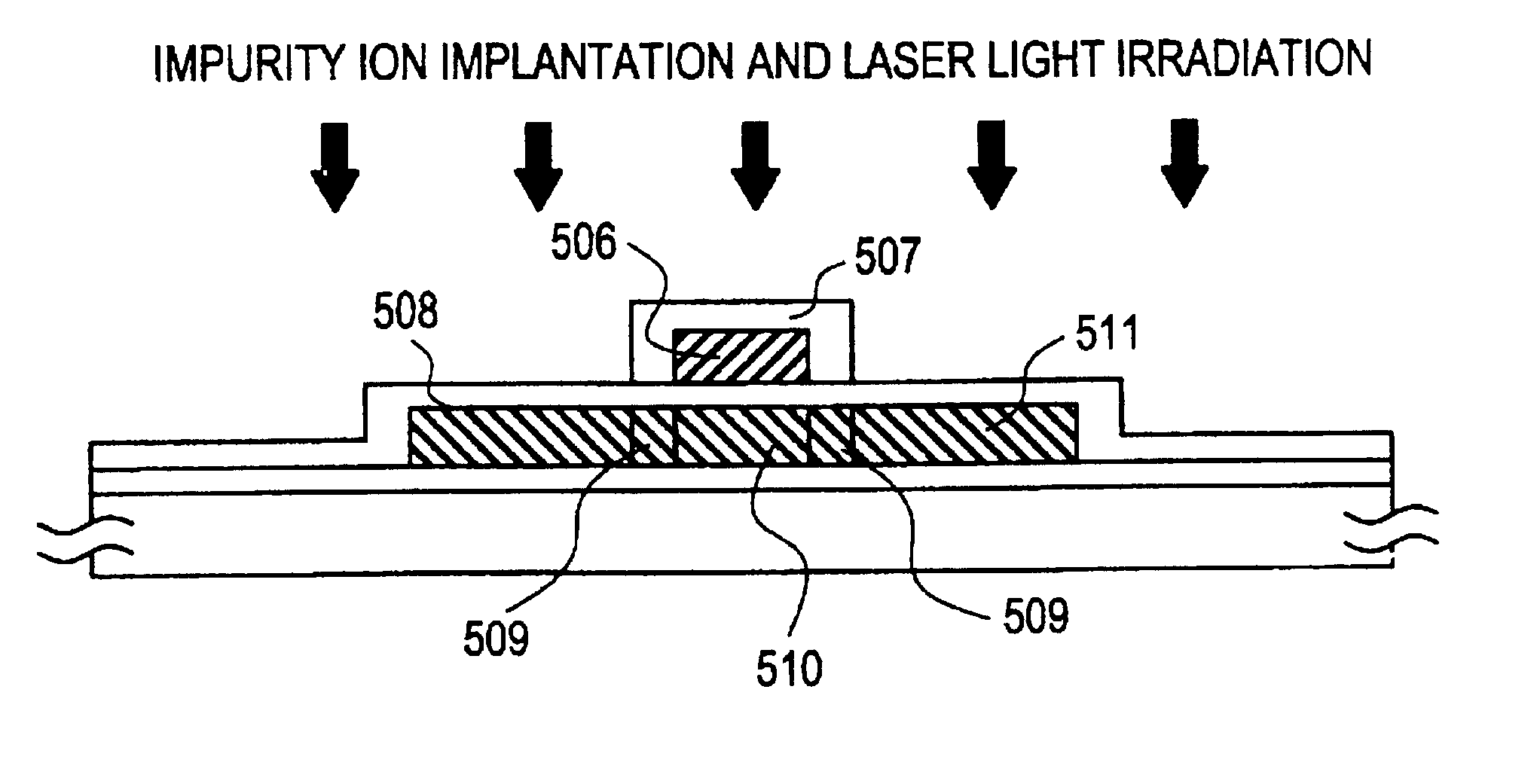

Then an aluminum film containing scandium is formed to a thickness of 6000 .ANG. followed by patterning the film to form a gate electrode denoted by reference numeral 506. Further, in the elect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Crystallization enthalpy | aaaaa | aaaaa |

| Semiconductor properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com