Garment hanger

a technology for garments and hangers, which is applied in the field of light weight, molded, plastic garment hangers, can solve the problems of i-section hangers prone to fractures, problems can develop, and develop fractures or breakages in these regions, and achieves the effects of increasing mass size, and reducing the risk of fractures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

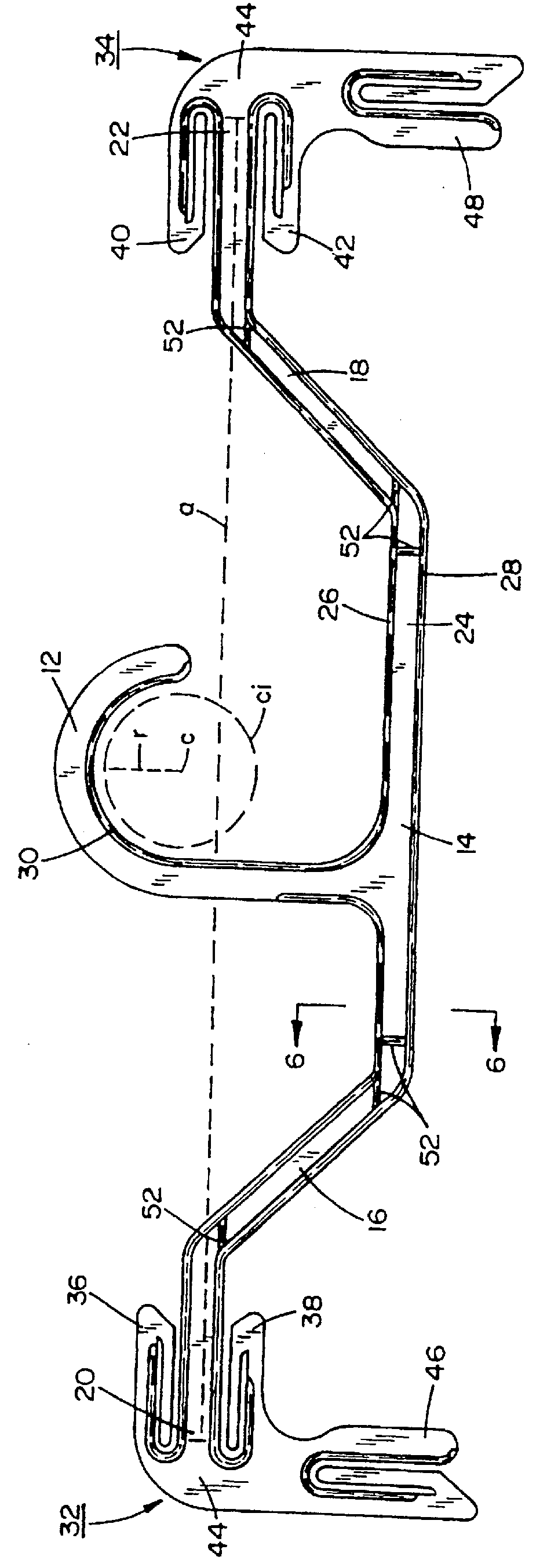

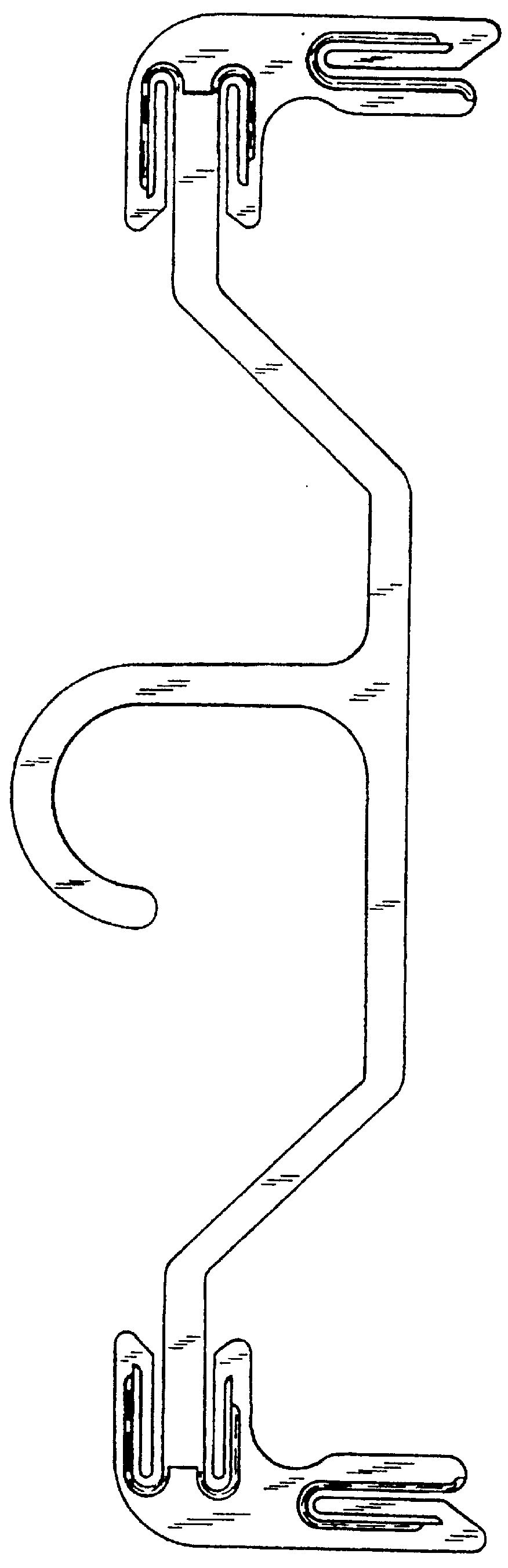

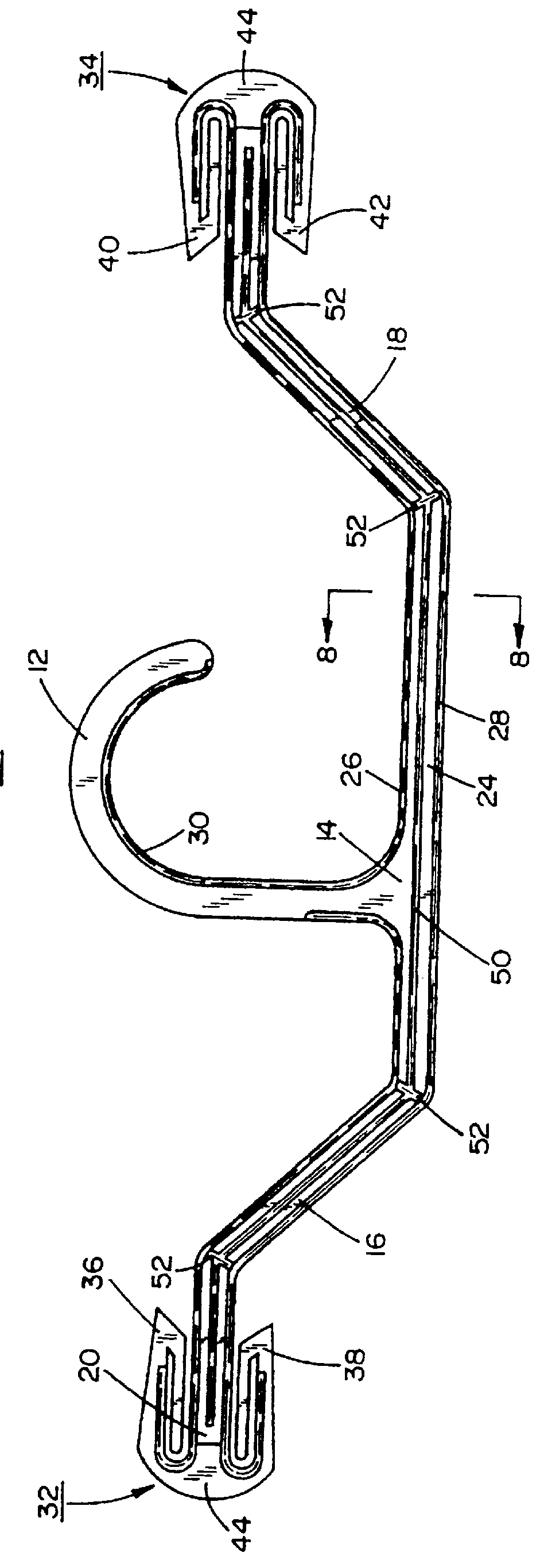

FIGS. 1-15 illustrate several garment hangers of the present invention. While the invention will be described and illustrated with respect to several intimate apparel hangers, it is understood that the invention is equally applicable to other types of garment hangers.

Referring now in detail to the drawings, and particularly, the hanger construction in FIG. 1, there is illustrated a front elevational view of a molded plastic garment hanger 10 having a central hook portion 12 which is integrally molded with hanger body 14, the latter of which includes a pair of coplanar oppositely directed upswept arms 16 and 18 each of said upswept arms ending with a clip end portion 20 and 22 for suspending one or more garments, as is well-known in the industry. The clip end portion 20 or 22 is then equipped with a suitable garment gripping or clipping structure.

In this first embodiment, it is preferred that said body member 14 and said upswept arms 16 and 18 are molded with a U-shaped cross-section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com