Concurrent engineering design tool and method

a technology of concurrent engineering and design tools, applied in the field of computer systems for automated concurrent engineering, can solve the problems of inability to reliably design subassemblies and abounding defective product designs, and achieve the effect of facilitating the selection of proper design approaches and reducing the time to market in the production of tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

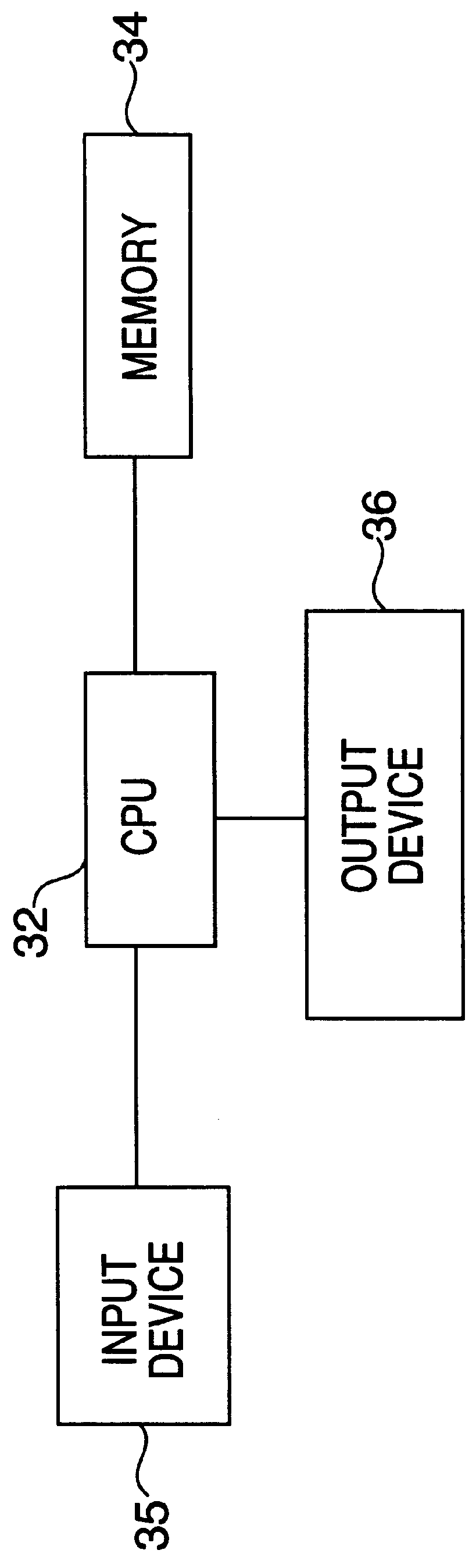

Image

Examples

example

The power of the approach of the present invention in generating both configurational and geometric design is best illustrated by example, in this case, in the field of plastics. The example involves the development effort in the design of injection molded plastic parts. It is noted that this field of use is only an example, and the scope of the invention is not so limited.

Successful design or injection molded plastic parts requires extensive knowledge of material properties and behavior, tooling, injection conditions and other processing parameters. This complex relationship between plastic product design and the cost and quality of the product demands design experts with many years of experience who understand the interaction of these variables.

Polymer part production is, by its very nature, an activity that demands concurrency. Advanced polymer materials derive their properties from the material's microstructure, and this microstructure evolves from the processing steps that tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com