Pulsed neutron generated prompt gamma emission measurement system for surface defect detection and analysis

a gamma emission measurement and neutron generation technology, applied in the direction of material analysis, material analysis using wave/particle radiation, instruments, etc., can solve the problem that the structural integrity of radioactive components or containers of radioactive materials resident in high radiation fields is difficult to assess using standard visual and ultrasonic non-destructive examination (nde) techniques, and achieve the effect of large fast neutron prompt capture gamma emission cross section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

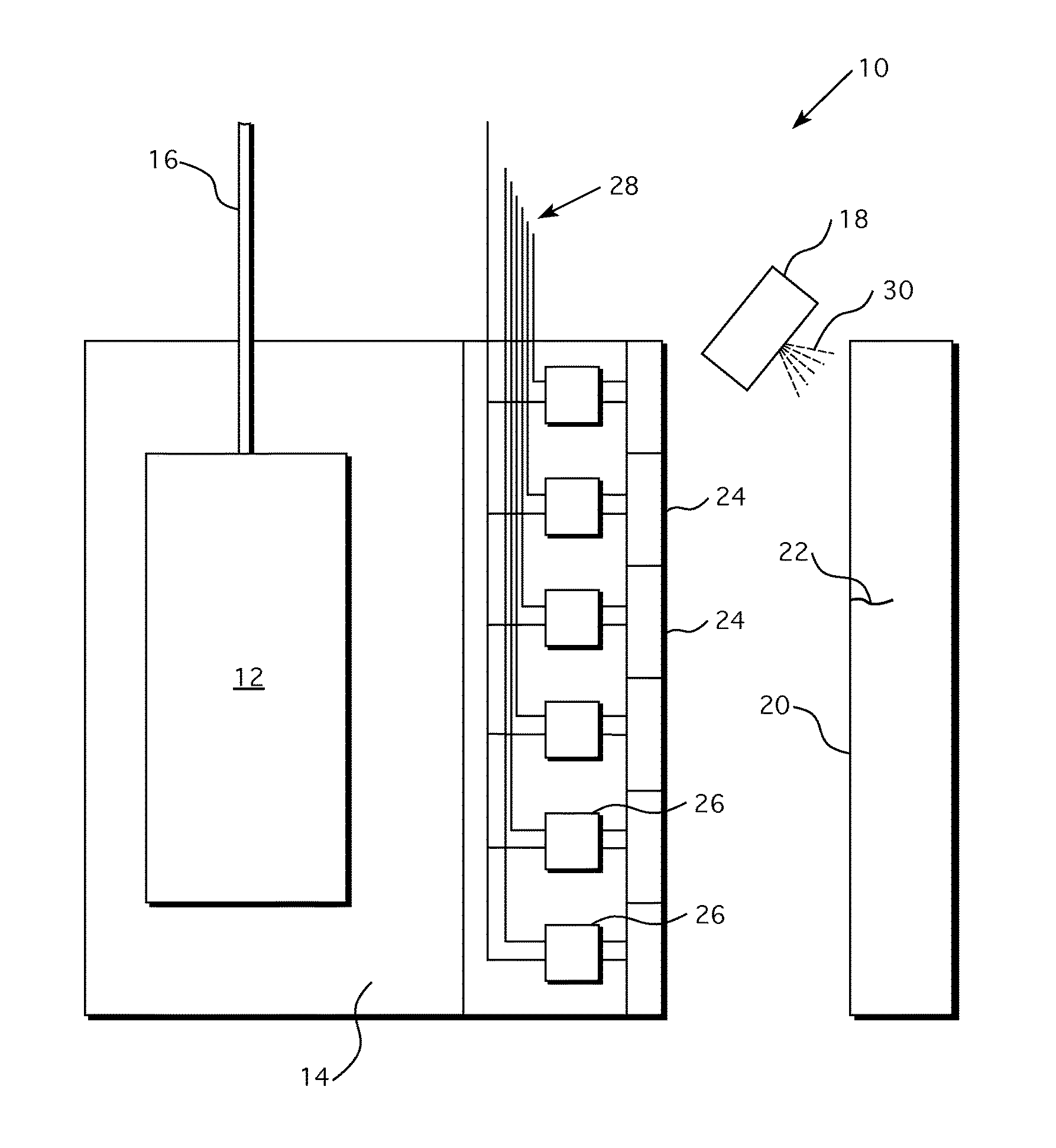

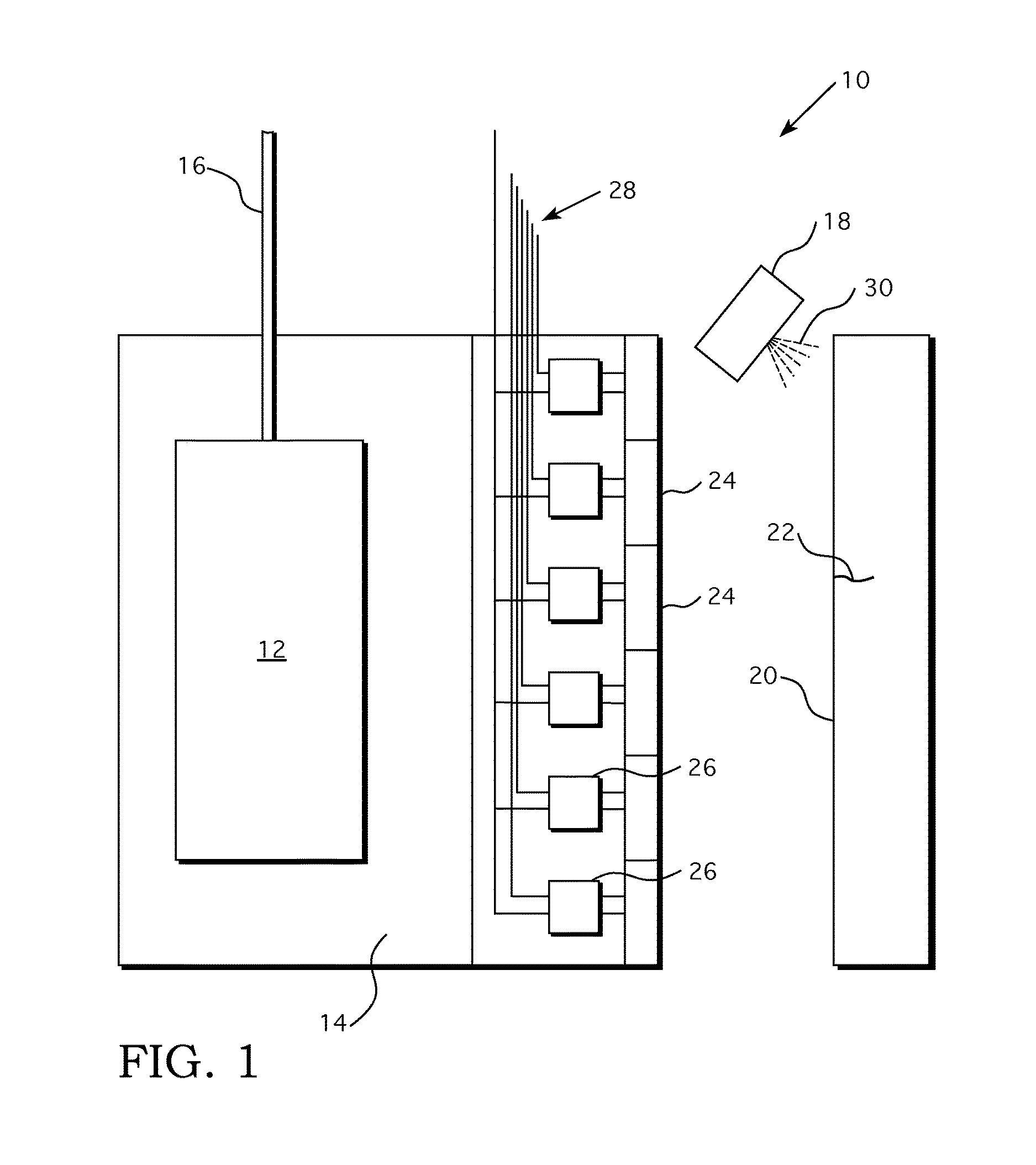

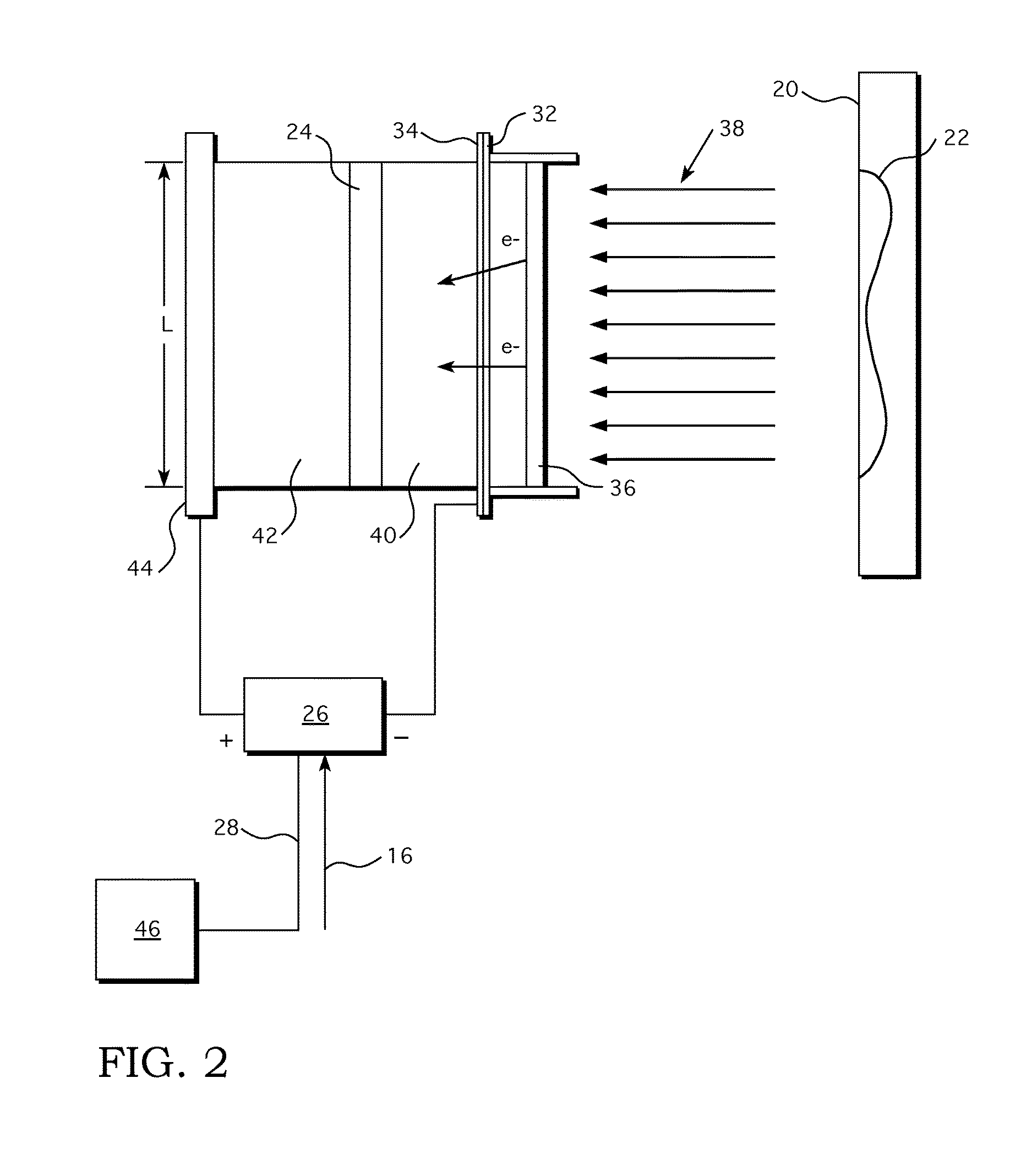

[0010]The operational bases for this invention are founded on a novel combination of dye-penetrant crack detection, prompt neutron gamma radiation detection, and planar Computerized Tomography (CT) techniques. The system also uses a novel SiC tuned gamma intensity detection method and a preamplifier for the very small SiC signal output based on Solid State Vacuum Tube technology. The preferred embodiment is as follows: A non-corrosive crack penetrant, preferably one high in Nitrogen content, or a crack penetrant such as Dynaflux Visible Dye Penetrant available from the Dynaflux Quality Products Company, Cartersville, GA, that is mixed with a chemical species containing a large proportion of an isotope that has a relatively large fast neutron prompt capture gamma emission cross section, such as Scandium, Vanadium, Manganese, or Titanium, is applied at a controlled temperature and pressure, as necessary to ensure the penetrant is in a liquid state when it reaches the surface being ins...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| structural defect | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com