Piezoelectric material and devices using the same

a piezoelectric element and piezoelectric material technology, applied in the field of piezoelectric elements, liquid discharge heads, ultrasonic motors, can solve the problems of polarizing bi, unclarified piezoelectric performance of lead components, and environmental impact of lead components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 11 and 16 to 26

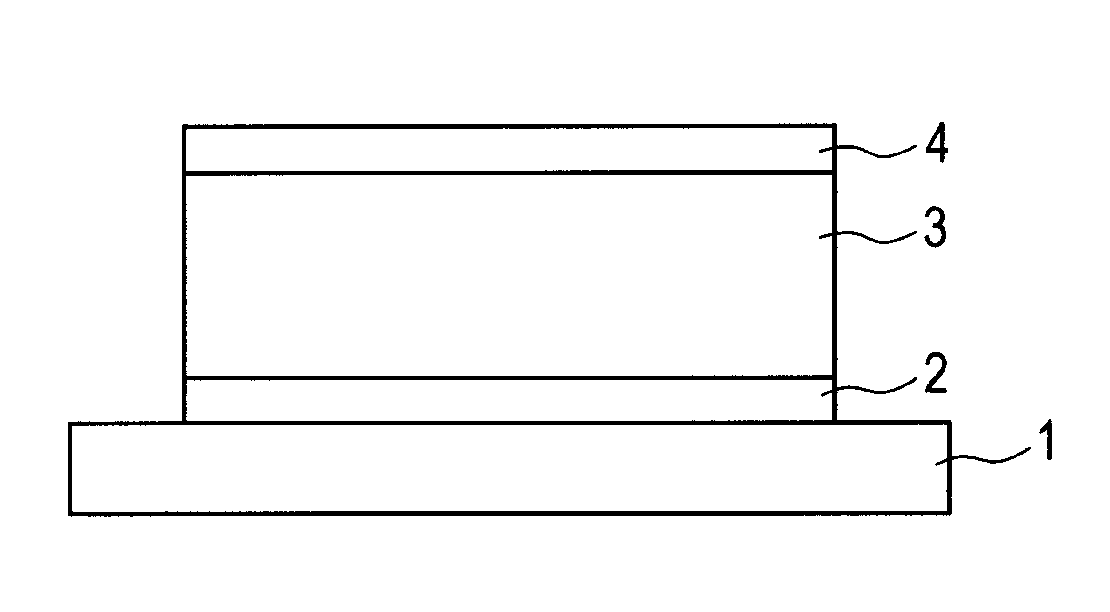

[0111]Metal oxide thin films having compositions corresponding to the respective examples of Table 1 and Table 3 were each formed on a substrate by an pulsed metal organic chemical vapor deposition method (MOCVD method).

[0112]A (100)-oriented strontium titanate (SrTiO3) single-crystal substrate having strontium ruthenate (SrRuO3) having a thickness of about 100 nm as a lower electrode on its film formation surface was used as the substrate on which any such thin film was formed. The SrRuO3 electrode was formed by a sputtering method.

[0113]There were used, as raw materials of the respective oxides of the metals, dimethyl(2-(N,N-dimethylaminomethyl)phenyl)bismuth (Bi(CH3)2(2-(CH3)2NCH2Ph)), tri(ethylpentadienyl)iron (Fe(C2H5C5H4)3), zinc bis(6-ethyl-2,2-dimethyl-3,5-decanedionate) (Zn(EDMDD)2), magnesium bis(2,2,6,6-tetramethyl-3,5-heptanedionate) (Mg(DPM)2), and tetra-i-propoxytitanium (Ti(O.i-Pr)4).

[0114]Nitrogen was used as a carrier gas, and oxygen and nitrogen were each used as a...

examples 12 and 27 to 41

[0128]Metal oxide thin films having compositions shown in Table 2 and Table 4 were each formed on a substrate by the MOCVD method in the same manner as in Examples 1 to 11 and 16 to 26.

[0129]A (110)-oriented strontium titanate (SrTiO3) single-crystal substrate having strontium ruthenate (SrRuO3) having a thickness of about 100 nm as a lower electrode on its film formation surface was used as the substrate on which any such thin film was formed. The SrRuO3 electrode was formed by a sputtering method.

[0130]There were used, as raw materials of the respective oxides of the metals, tri(2,2,6,6-tetramethyl-3,5-heptanedionate) (2,2-bipyridyl)lanthanum (La(TMOD)3bpy) and manganese tri(2,2,6,6,-tetramethyl-3,5-heptanedionate) (Mn(DPM)3), in addition to the raw materials used in Examples 1 to 11.

[0131]A thin film based on the piezoelectric material of the present invention having a thickness of 200 nm to 450 nm was obtained under the same film formation conditions as those of Examples 1 to 11...

examples 13 , 14

Examples 13, 14, and 42 to 57

[0138]Metal oxide thin films having compositions shown in Table 2 and Table 5 were each formed on a substrate by the MOCVD method in the same manner as in Examples 1 to 12 and 16 to 41.

[0139]A (111)-oriented strontium titanate (SrTiO3) single-crystal substrate having strontium ruthenate (SrRuO3) having a thickness of about 100 nm as a lower electrode on its film formation surface was used as the substrate on which any such thin film was formed. The SrRuO3 electrode was formed by a sputtering method.

[0140]There was used in Examples 13 and 14, as raw materials of the respective oxides of the metals, aluminum tri(2,2,6,6-tetramethyl-3,5-heptanedionate) (Al(DPM)3), in addition to the raw materials used in Examples 1 to 12 and 16 to 41.

[0141]A thin film based on the piezoelectric material of the present invention having a thickness of 210 to 550 nm was obtained under the same film formation conditions as those of Examples 1 to 12 and 16 to 41.

[0142]x, j, k, l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com