Method for preparing a carbon/carbon composite

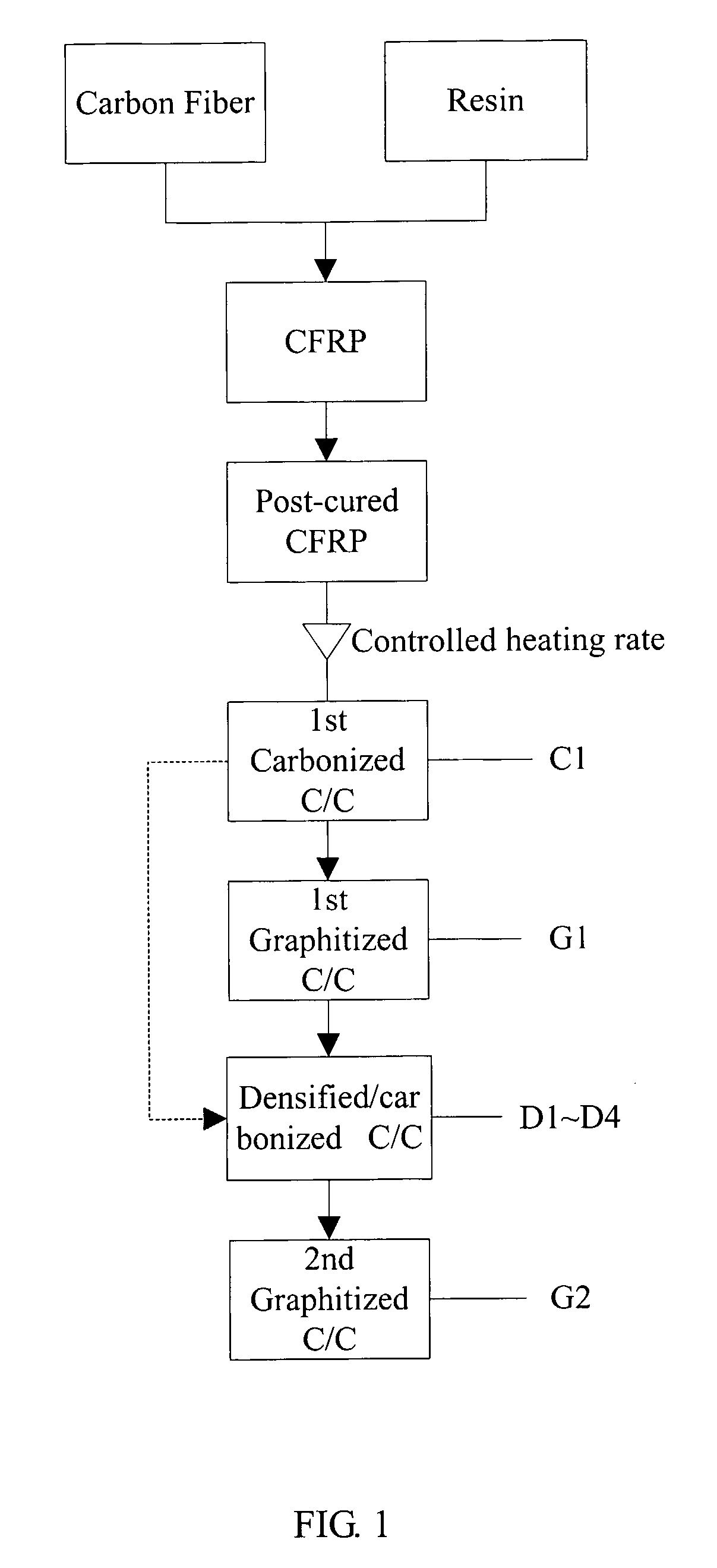

a carbon/carbon composite and composite technology, applied in the field of carbon/carbon composite preparation, can solve the problems of localized delamination and/or other damage to the matrix structure, and achieve the effects of high heating rate, acceptable tribological performance, and comparable mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0057]C / C composites were prepared from different fiber volume fractions and carbonization rates. The carbon fibers were random type. The specimen dimensions were 50×20×10 mm. The samples were processed to stage C1. The PAN-based carbon fibers (Torayca T700S, 12K, Toray Co., Japan), chopped to length 4.5 mm were first impregnated with a resole-type phenolic resin (PF-650, Chang Chun Petrochemical Industry, Taiwan) in a plastic mold in vacuum to form a prepreg. The prepreg was placed in an oven at 70° C. for 6 hours to remove excess solvent, followed by a hot press curing process in a stainless steel mold at 400 psi, and 160° C. for 30 min. The cured composite was sectioned into 50 mm×20 mm×10 mm coupons using a water-cooled diamond saw, followed by a post-curing process at heating rate 1° C. / min till 160° C., then 0.5° C. / min to 230° C., held for 2 hours in an air-circulated oven.

[0058]Carbonization was conducted by heating the post-cured composite in nitrogen atmosphere to 1000° C....

example 2

[0080]The procedures of example 1 were repeated with six different kinds of fibers. A fixed fiber volume fraction (50 vol %) and two different carbonization rates, 100 and 600° C. / min, were used. The properties were determined using the same method as in Example 4.

[0081]L: Toray T-700S PAN-based fiber, chopped to length 12 mm

[0082]H: Toray T-700S PAN-based fiber, chopped to length 4.5 mm

[0083]P: Thorne P25W pitch-based fiber, chopped to length 12 mm

[0084]T: Toray T-300 PAN-based fiber, chopped to length 12 mm

[0085]PW: PAN-based 2D woven cloth[0086]Resin: Phenolic resin PF-650 (resole-type)[0087]Hot press: 400 psi, 160° C. for 30 min.[0088]Specimen dimensions: 50×20×10 mm

Carbonization Rate:[0089](1) 100° C. / min till 1200° C., held for 3 min.[0090](2) 600° C. / min till 1200° C., held for 3 min.

Furnace for Carbonization Process:[0091]High temperature tube furnace (Model Number: F59348CM, Barnstead / Thermolyne, USA)

Sample Process Stage: C1

Measurements[0092]Density ...

example 3

[0102]The PAN-based carbon fibers (Torayca T700S, 12K, Toray Co., Japan), chopped to length 4.5 mm were first impregnated with the Resole-type phenolic resin (PF-650, Chang Chun Petrochemical Industry, Taiwan) in a plastic mold in vacuum to form a prepreg. The carbon fibers were random type. The prepreg was placed in an oven at 70° C. for 6 hours to remove excess solvent, followed by a hot press curing process in a stainless steel mold with a vacuum bag at 400 psi and 160° C. for 30 min. The cured composite was sectioned into 50 mm×10 mm×2.5 mm coupons using a water-cooled diamond saw, followed by a post-curing process at heating rate 1° C. / min. till 160° C., then 0.5° C. / min. to 230° C., hold for 8 hr. in an air-circulated oven.

[0103]Carbonization was conducted by heating the post-cured composite in nitrogen atmosphere to 1200° C. at five different heating rates: 1, 15, 100, 300 and 1000° C. The carbonization at heating rates 1 and 15° C. / min were conducted in an ordinary furnace h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com