Optical element and optical scanning device using the same

a scanning device and optical element technology, applied in the field of optical element and optical scanning device using the same, can solve the problems of difficult application of anti-reflection coating to the lens surface of a plastic lens, insufficient disclosure of arrangement of two-dimensionally arranged gratings, and insufficient disclosure of lens surface anti-reflection coating, etc., to achieve the effect of reducing fresnel (surface) reflection and reducing fresnel reflection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

[0075]An optical element according to the present invention is an optical element in which a subwave structural grating is provided on at least one optical surface. The subwave structural grating has an anti-reflection function associated with an incident angle of a light beam.

[0076]The optical element according to the present invention is applicable to various optical systems such as an image taking system, a projection system, and an image forming system, in which the incident angle is changed from a center portion of the element to a peripheral portion thereof.

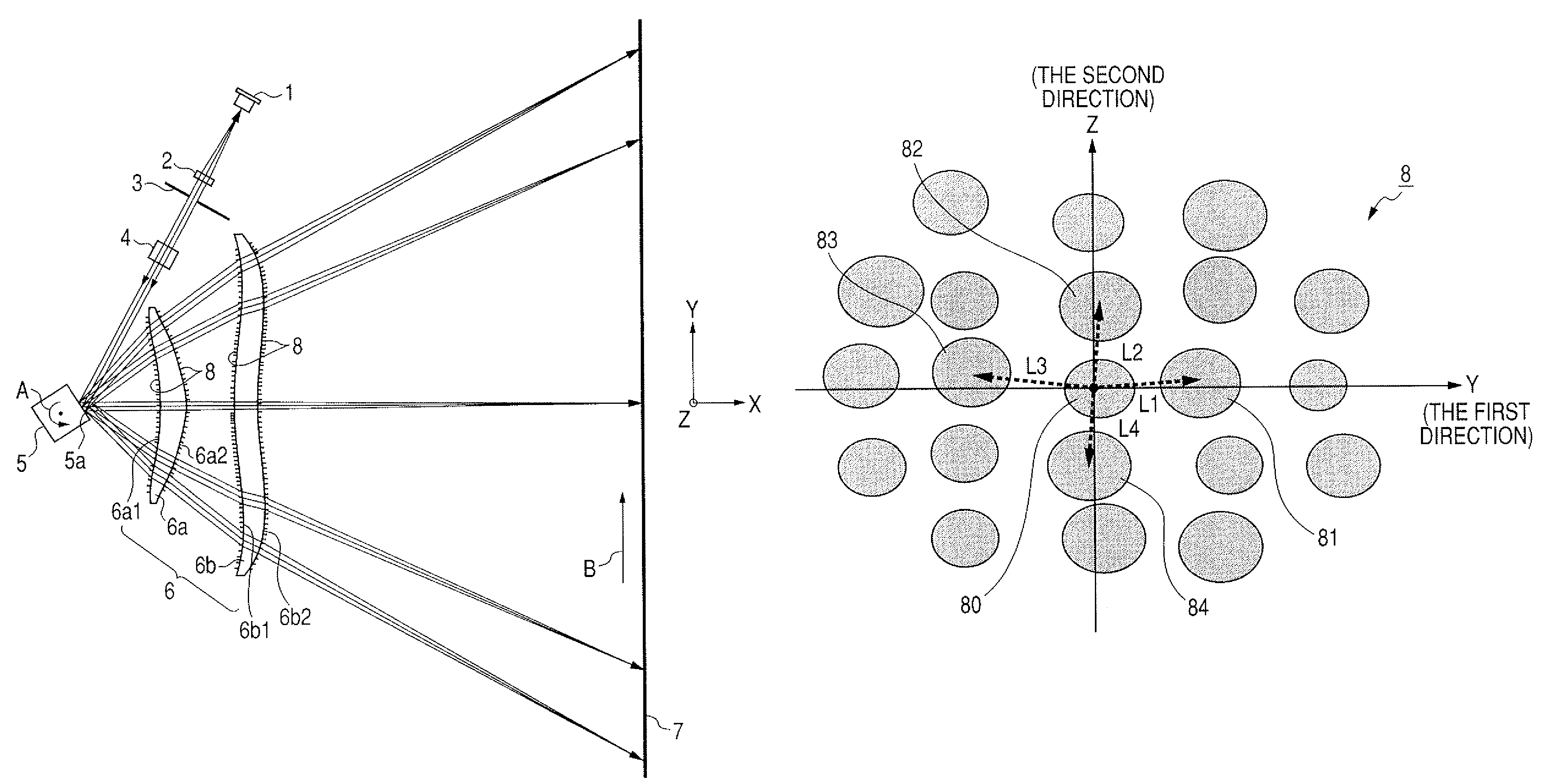

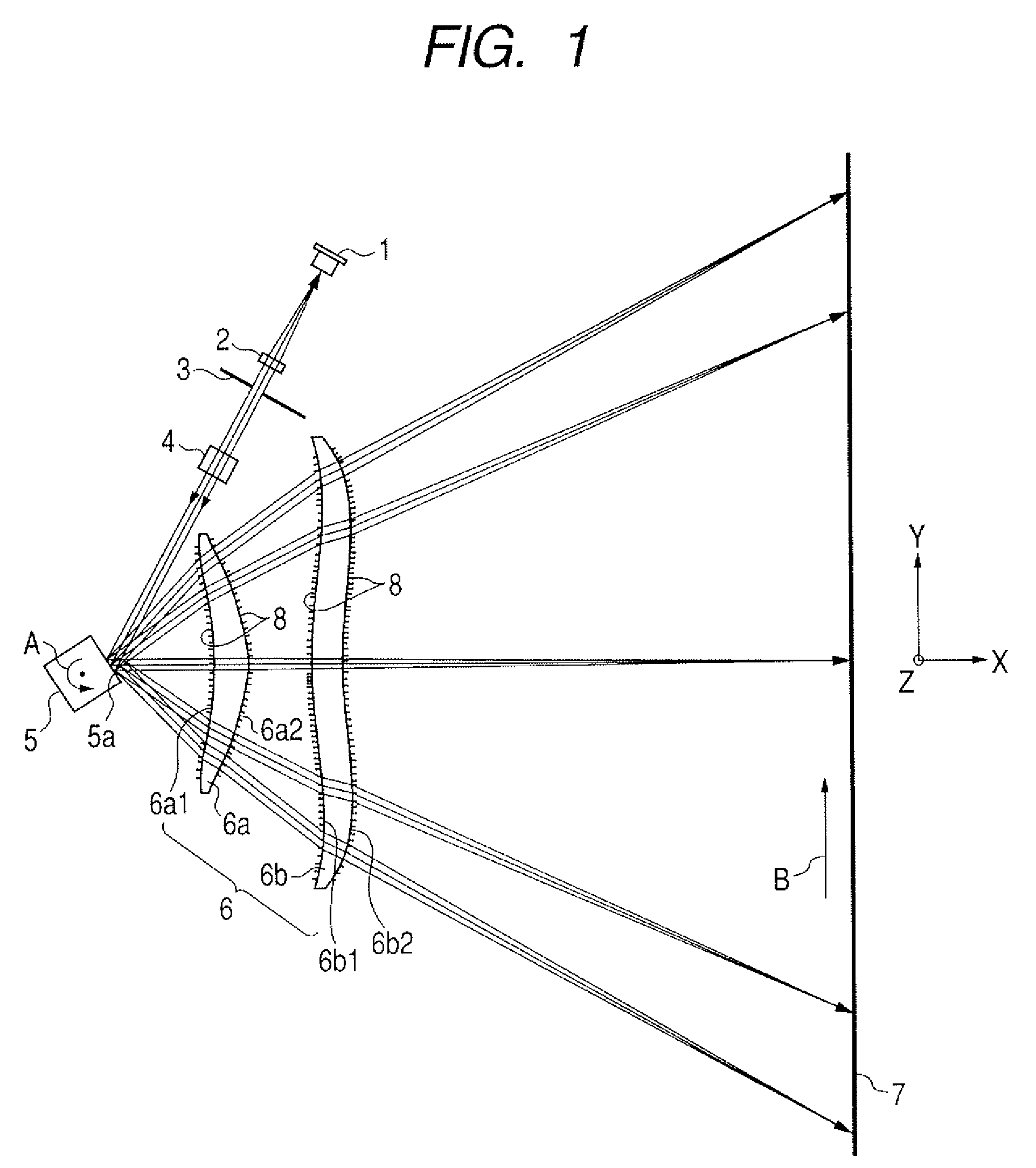

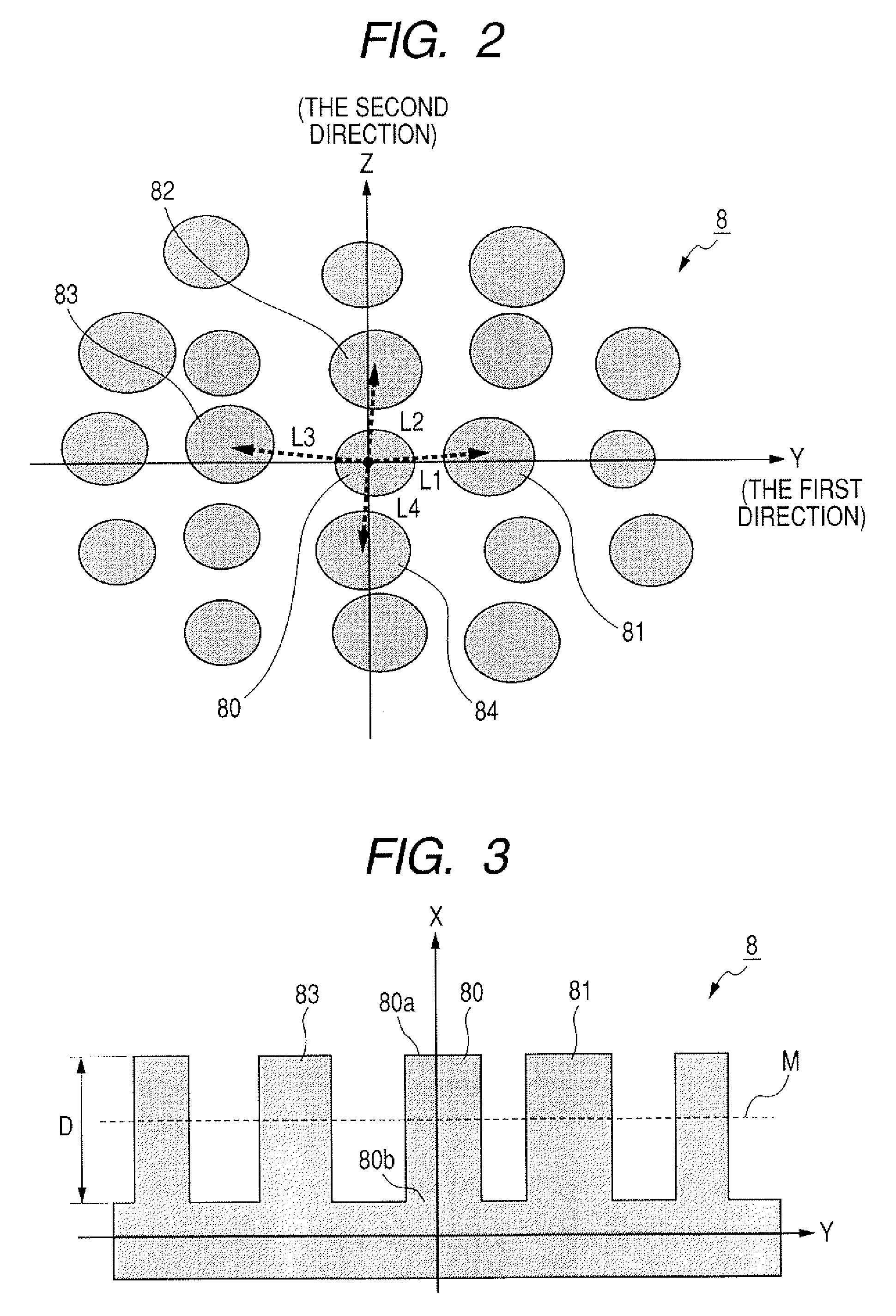

[0077]Next, Embodiment 1 in which the optical element according to the present invention is applied to an optical scanning device will be described with reference to FIGS. 1 to 6. FIG. 1 is a cross sectional view of a principle part of the optical scanning device in a main scanning direction (main scanning sectional view) according to Embodiment 1 of the present invention. In FIG. 1, a Y-axis is set in a scanning direction ...

embodiment 2

[0136]Embodiment 2 of the present invention will be described with reference to FIGS. 7 to 13.

[0137]A point in this embodiment which is different from Embodiment 1 described earlier is that a subwave structure whose cross sectional shape is a deformed circle is formed in a convex shape. Other structures and optical functions are substantially identical to those of Embodiment 1 and thus the same effect is obtained.

[0138]That is, in this embodiment, each of the incident surface 6a1 of the first imaging lens 6a in the imaging optical system 6, the exit surface 6a2 thereof, the incident surface 6b1 of the second imaging lens 6b therein, and the exit surface 6b2 thereof has a special aspherical shape as a base shape. A subwave structural grating 89 shown in FIGS. 7 to 9 is formed in each of the surfaces.

[0139]Therefore, reflectance (and transmittance) can be arbitrarily controlled in this embodiment. Thus, Fresnel (surface) reflection caused on each of the incident surface 6a1 of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com