Walk reel mower

a mower and reel technology, applied in the direction of agriculture tools and machines, propulsion using engine-driven generators, transportation and packaging, etc., can solve the problems of jerk or discontinuity, jerk or discontinuity felt by the operator in the handle as the operator pushes down on the handle to raise the cutting unit, and disadvantages of the chain support uni

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

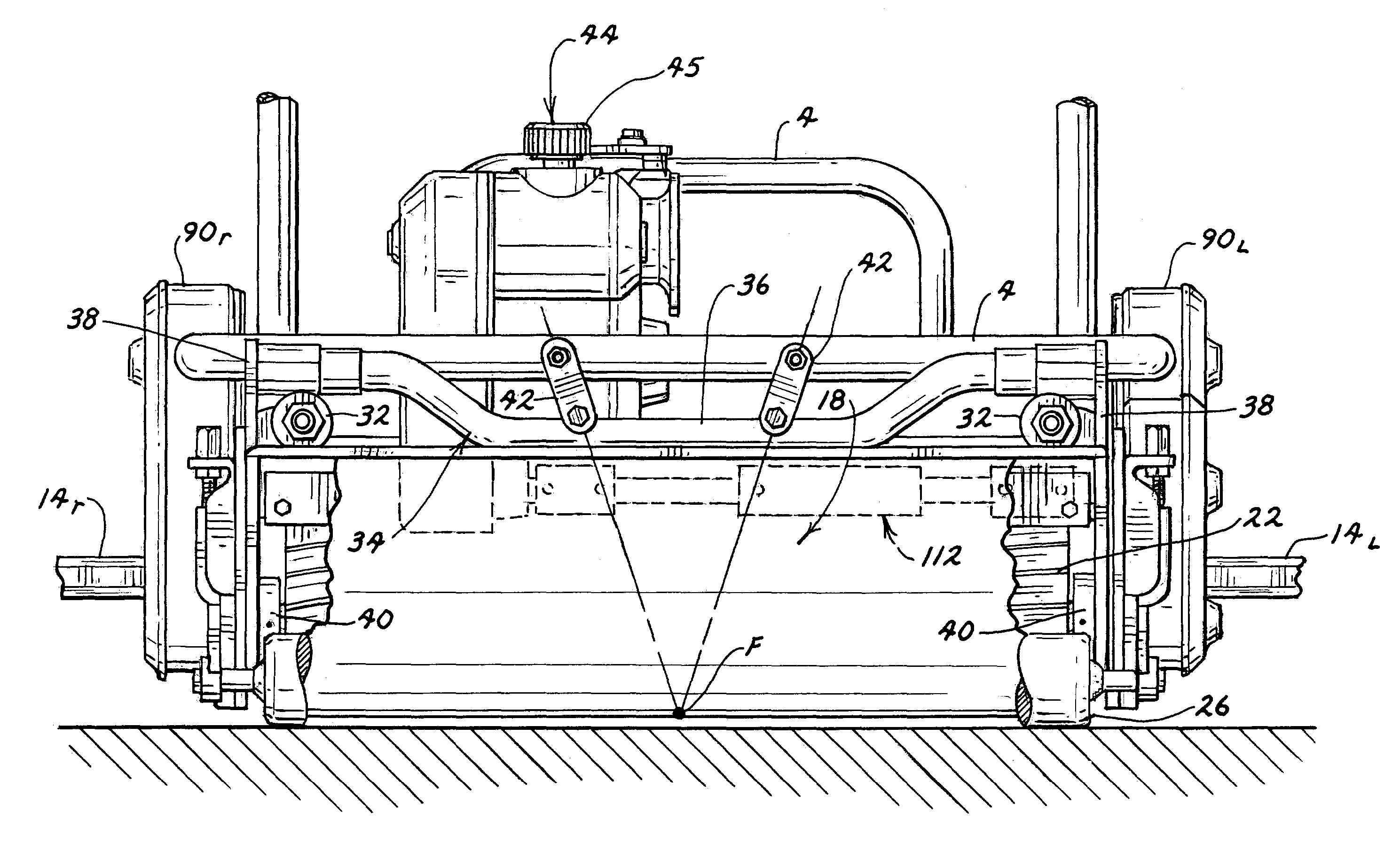

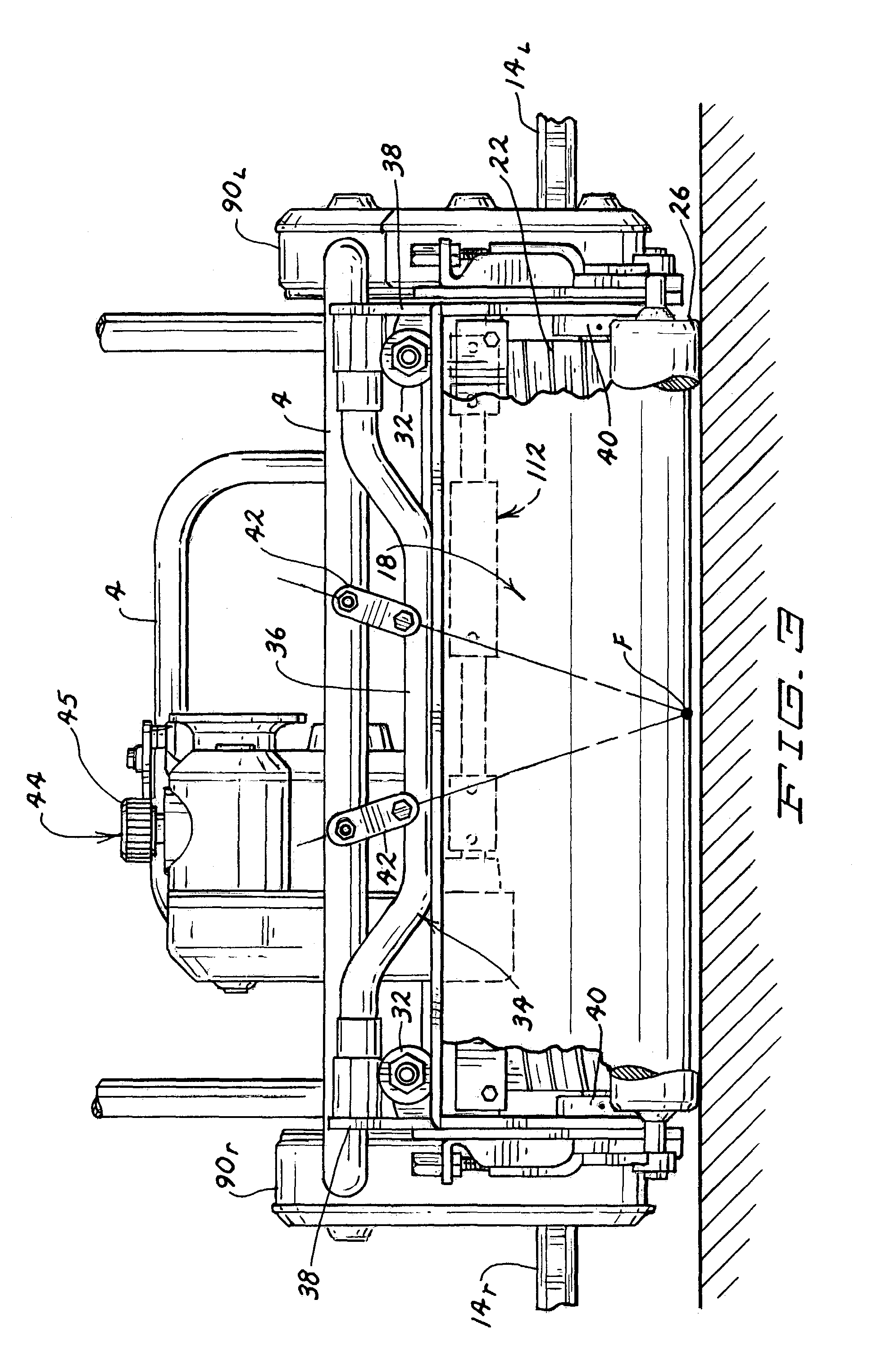

[0052]This invention relates to a walk reel mower 2 having a reel cutting unit for cutting grass. The term “walk reel mower” is used in this application to refer to a walk reel mower 2 in which the operator walks behind walk reel mower 2 as walk reel mower 2 is operated. The operator is not supported or carried by walk reel mower 2 as would be the case with a riding reel mower. More particularly, walk reel mower 2 is suited for mowing grass at low heights of cut where precision cutting is required, such as on the greens of a golf course. However, the various aspects of the invention disclosed herein are not limited for use on a walk reel mower for mowing only golf greens, but can be used on walk reel mowers for mowing other turf areas as well.

The Overall Walk Reel Mower

[0053]FIG. 1 provides an overall view of one embodiment of a walk reel mower 2 according to this invention. Walk reel mower 2 includes a frame 4 on which a power source 6, such as an internal combustion engine, is car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com