Stacked-plate gas-expansion cooler assembly, fabrication method, and use

a gas expansion cooler and stacked plate technology, applied in the direction of lighting and heating apparatus, container discharging methods, instruments, etc., can solve the problems of unacceptably long, cryogenic operating temperature on the order, time required to cool the light sensor from room temperature, etc., to achieve the effect of absorbing greater heat from the cooled device and increasing cooling power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

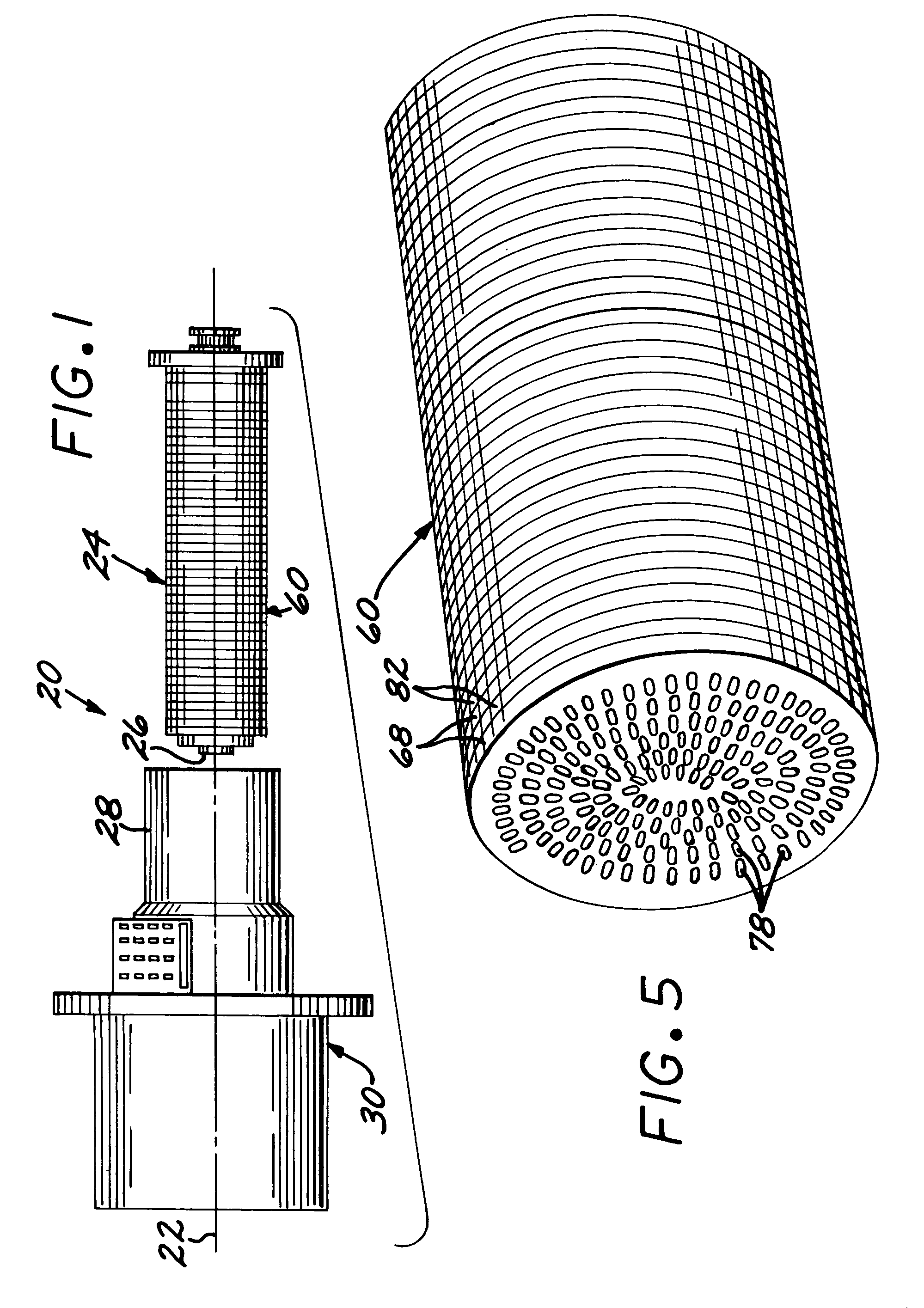

[0027]FIG. 1 depicts in partially exploded view a gas-expansion cooler assembly 20 having an assembly axis 22. The gas-expansion cooler assembly 20 includes a gas expansion cooler 24, and a cooled device 26 mounted thereto. The gas-expansion cooler 24 and cooled device 26 are received in a fitting 28 of a vacuum dewar 30.

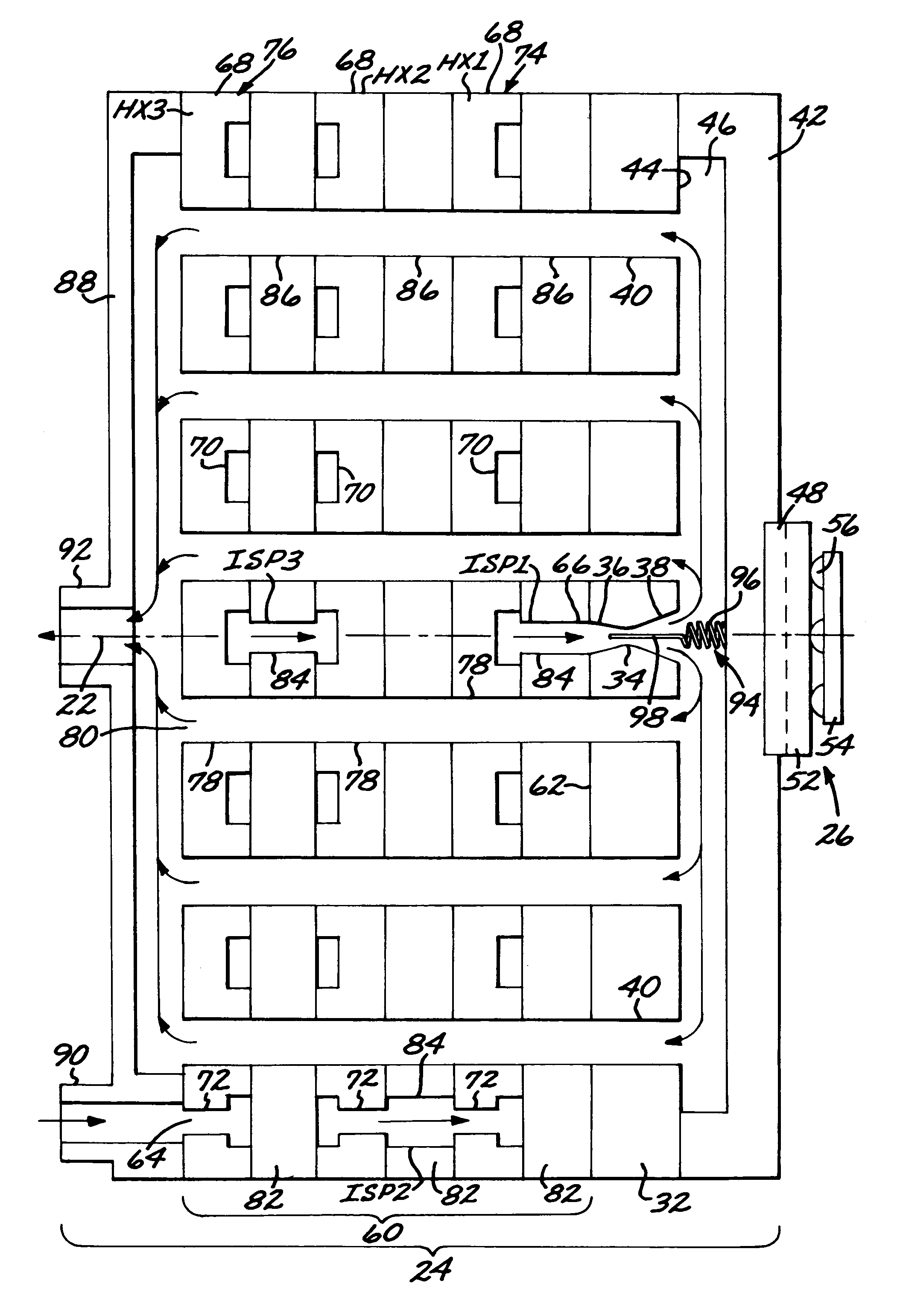

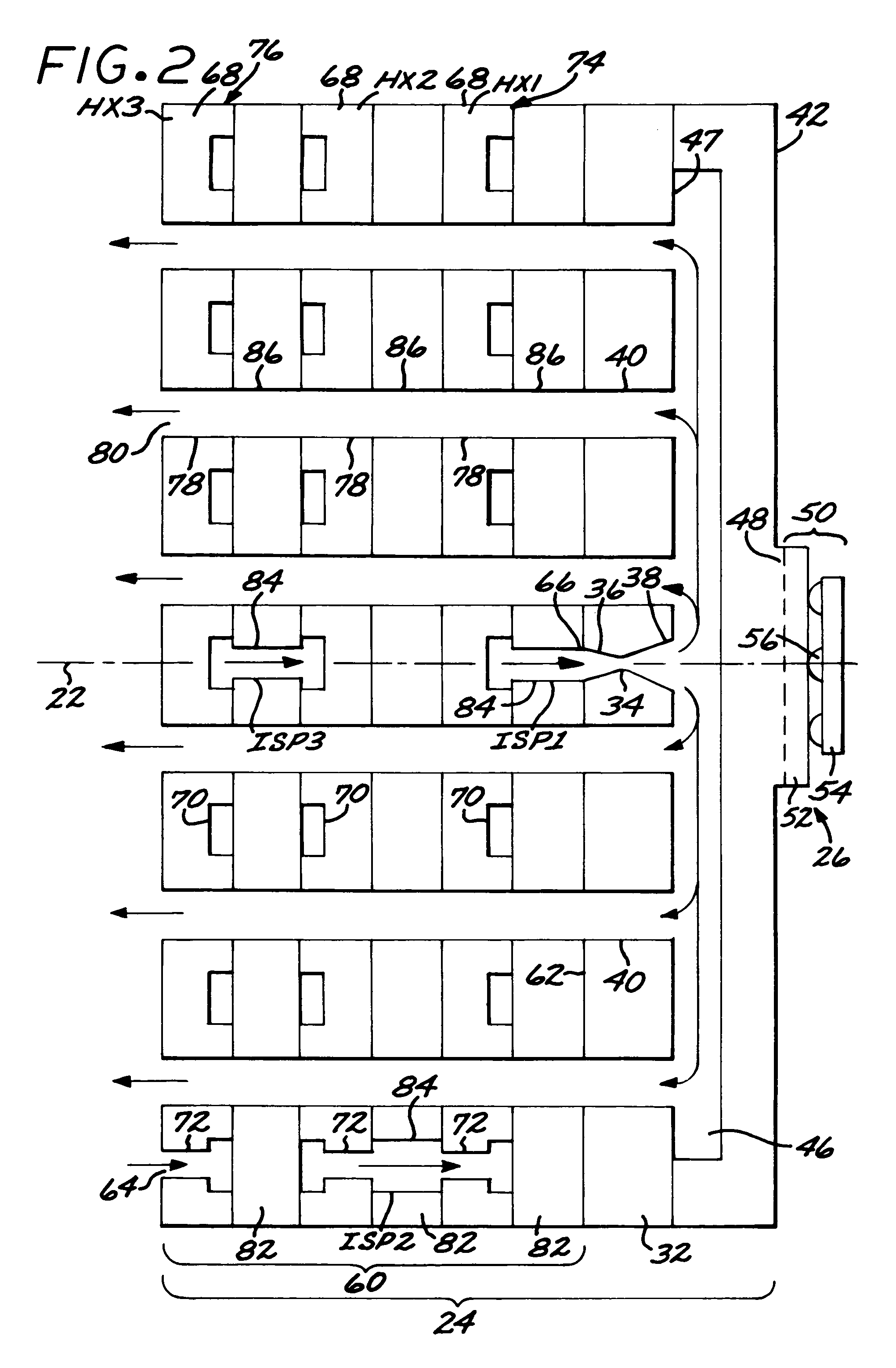

[0028]As seen in FIGS. 2 and 3, a preferred form of the gas-expansion cooler 24 is made of a series of plates having gas-flow channels therein. The embodiments of FIGS. 2 and 3 are similar, and the same description is applicable to both figures except as will be discussed subsequently. The plates that form the gas-expansion cooler 24 are all substantially flat, so that they may be stacked together. The plates all preferably have a cylindrical periphery, so that they form a cylindrical structure as shown in FIG. 1 and in FIGS. 4–5.

[0029]The gas-expansion cooler 24 includes an expansion plate 32 having an expansion orifice 34 therein. The expansion orifice 34 has an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com