Coding symbology and a method for printing same

a technology of coding and symbology, applied in the field of coding symbology, can solve the problems of increasing scrap rate, affecting patient safety, and requiring several hours or even days to manufacture, so as to reduce potentially patient safety errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

1. Coding Symbology with a Single Bar Code

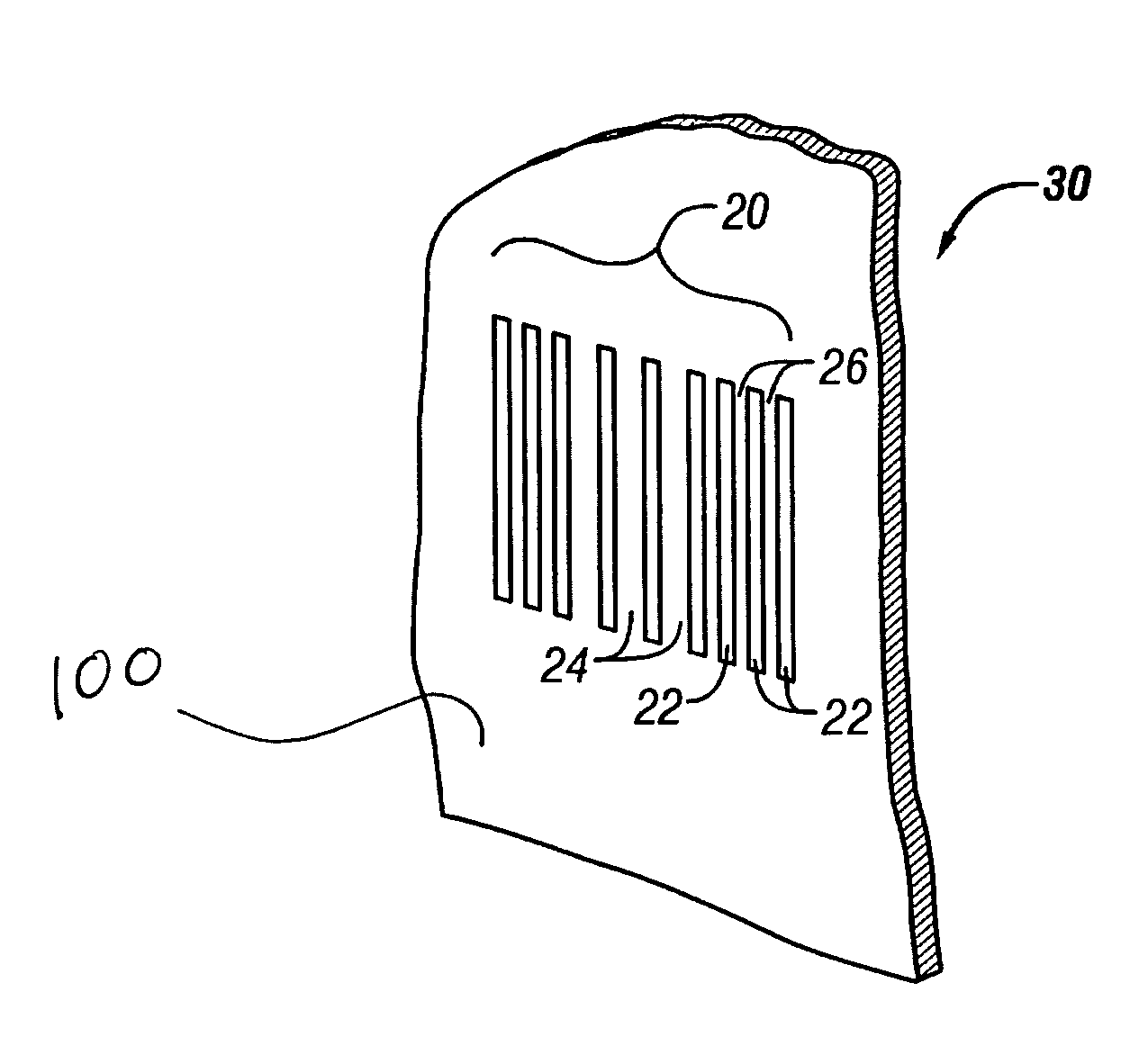

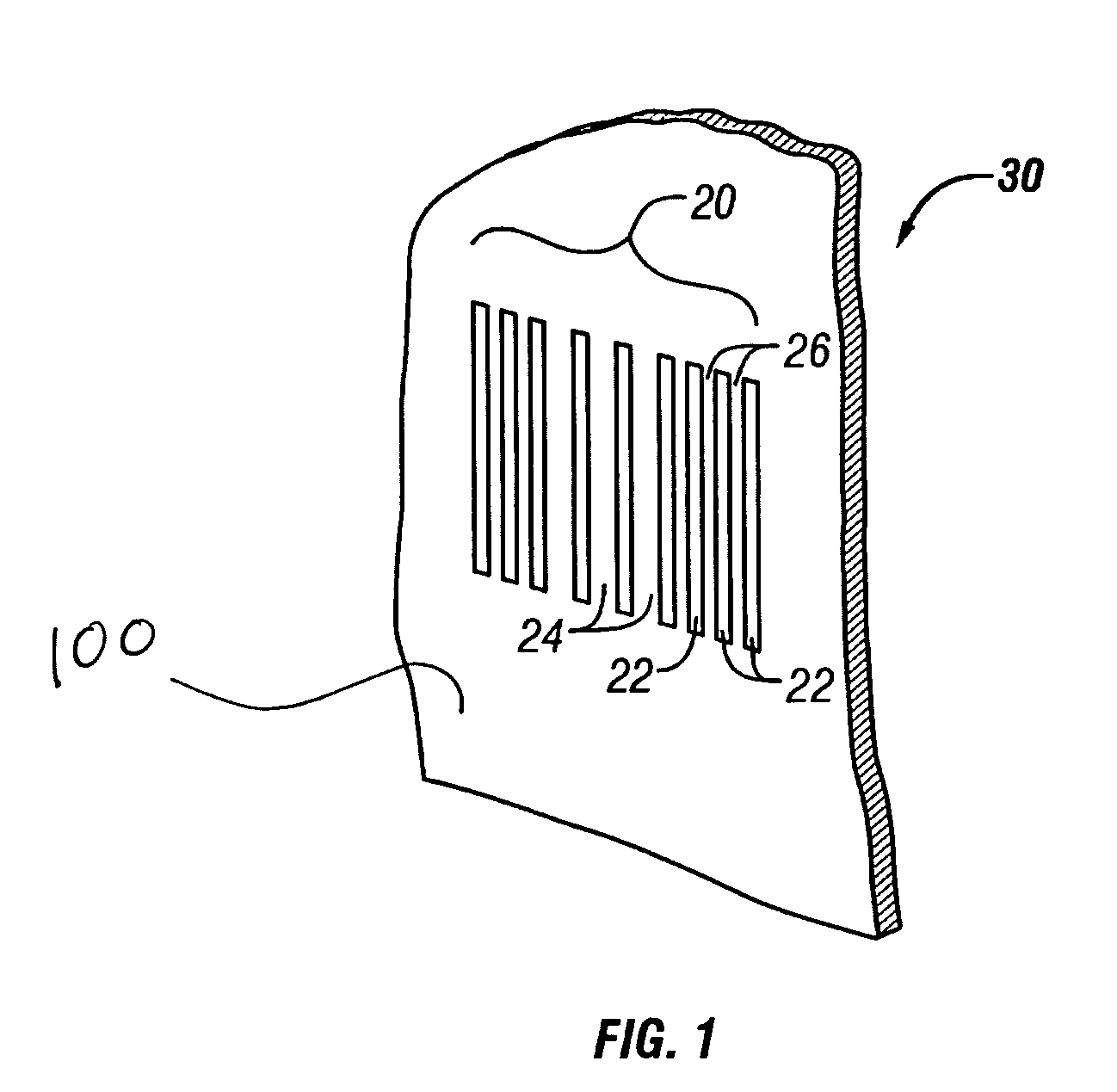

[0048]As stated above, the identification system of the present invention provides a coding symbology disposed on a substrate. The invention further provides that a plurality of light-reflecting segments, which are separated by spaces, is disposed on the substrate. The unmolested area of the substrate beneath the light-reflecting segments defines light-absorbing segments. Together, the light-reflecting segments and the light-absorbing segments define an image of a bar code. In a preferred form of the invention, the light-reflecting segments and the light-absorbing segments define a negative image of a bar code.

2. Coding Symbology with Two or More Bar Codes

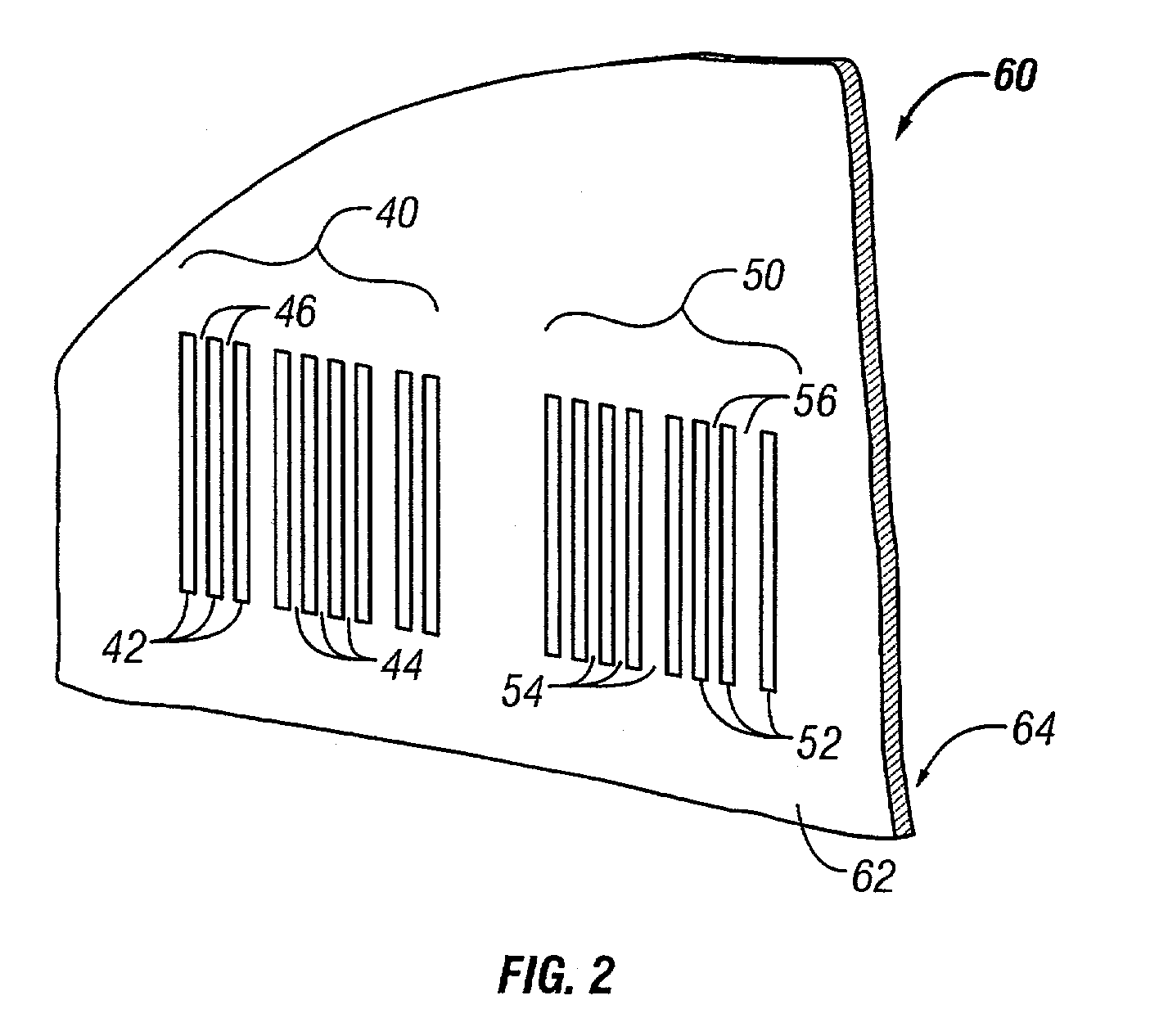

[0049]When a second bar code is used, it is formed in the same general manner as the first bar code. That is, a second plurality of light-reflecting segments, which are separated by spaces, is disposed on the substrate. The unmolested area of the substrate beneath the light-reflecting segme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com