Power adapter with heat sink device

a technology of power adapters and heat sinks, which is applied in the direction of cooling/ventilation/heating modifications, solid-state devices, semiconductor devices, etc., can solve the problems of power adapters that cannot employ dispersing fans, the heat of the power transforming device is trapped in the insulating casing, and the power adapter cannot use a dispersing fan, so as to prevent heat from concentrating and even dispersing heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

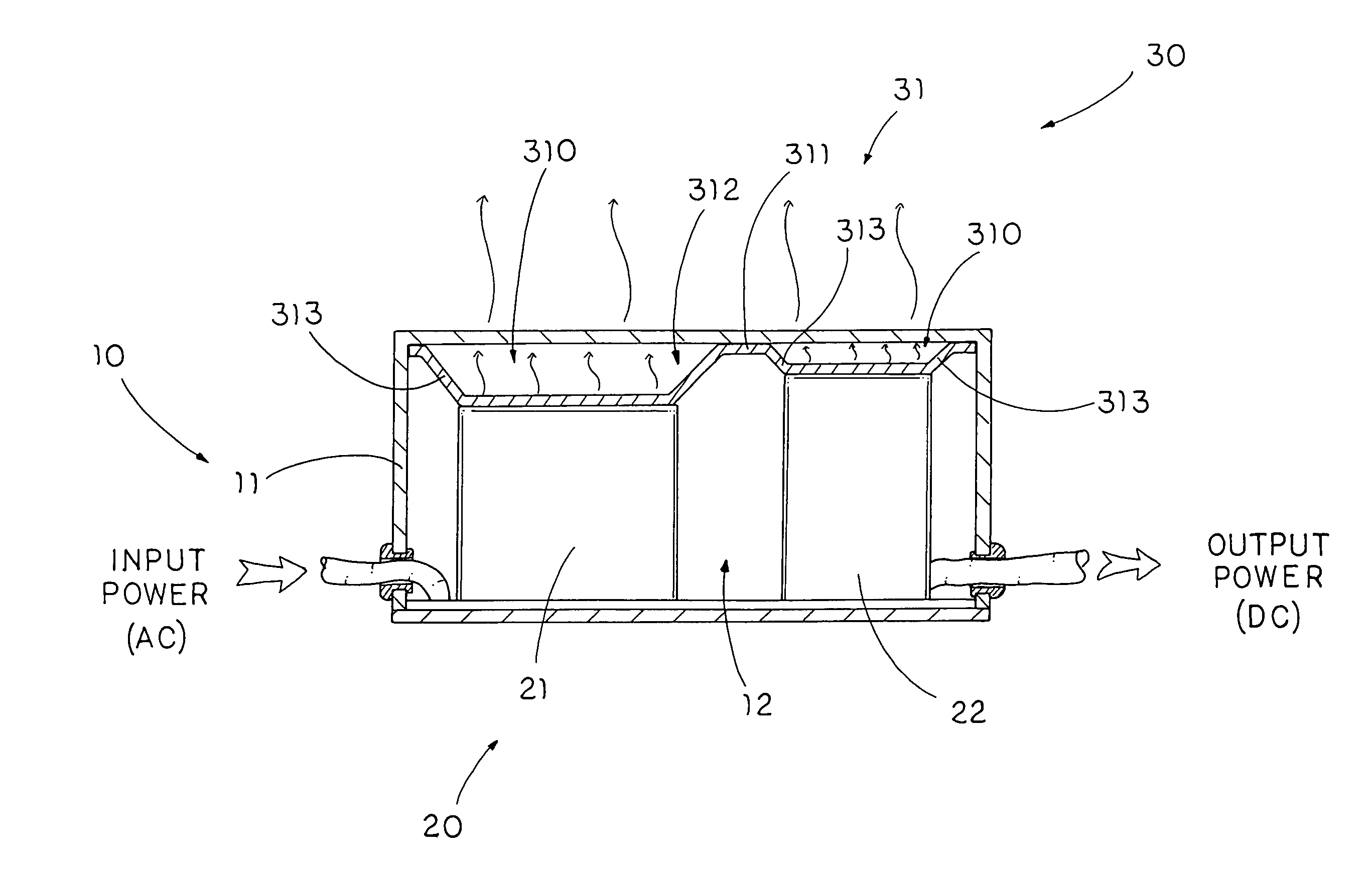

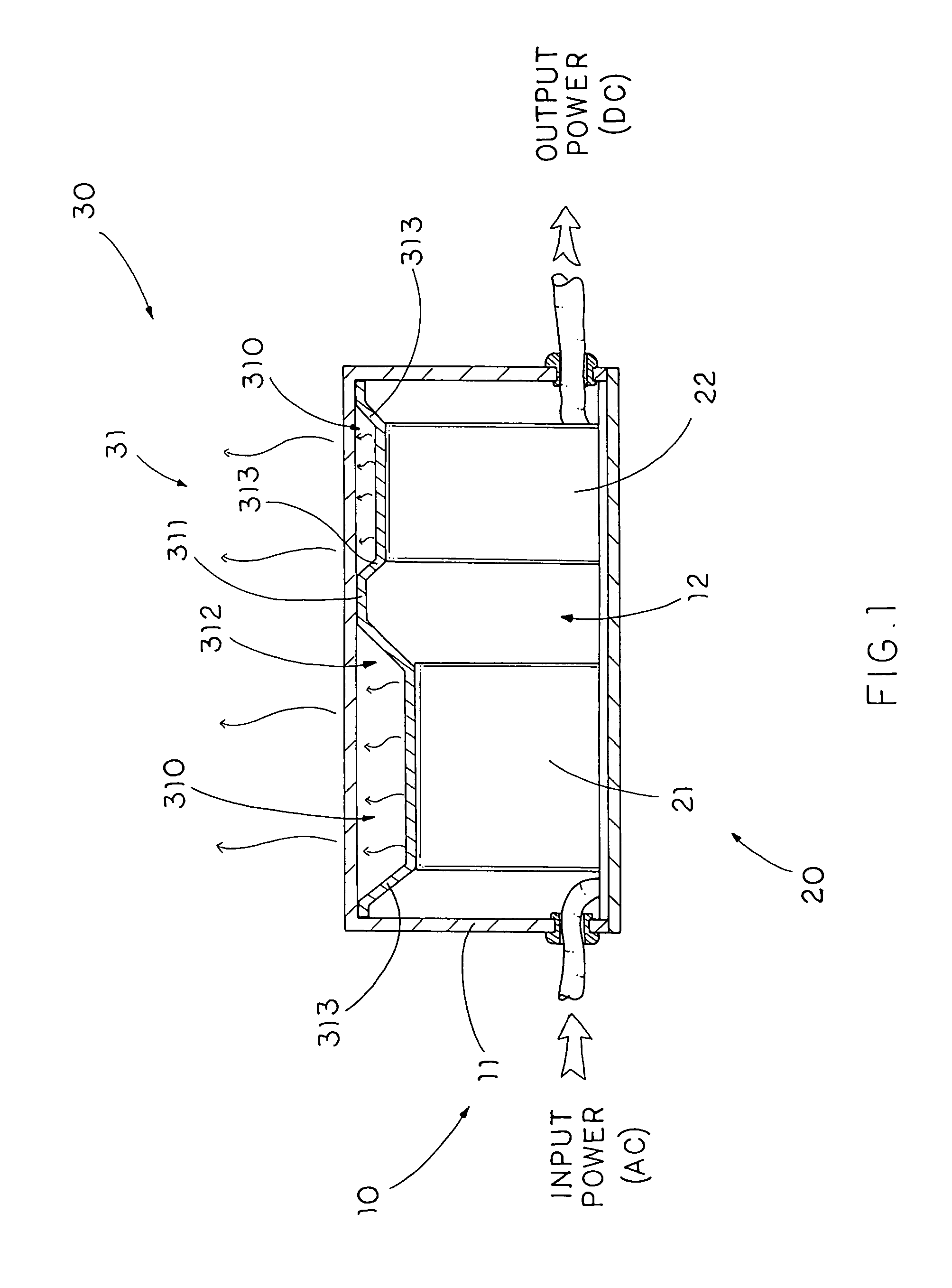

[0023]Referring to FIG. 1 of the drawings, a power adapter according to a preferred embodiment of the present invention is illustrated, wherein the power adapter comprises an insulating casing 10 which comprises an enclosing wall 11 and defines a sealing chamber 12 therein and a power transforming unit 20 disposed in the sealing chamber 12 for converting an input power into an output power.

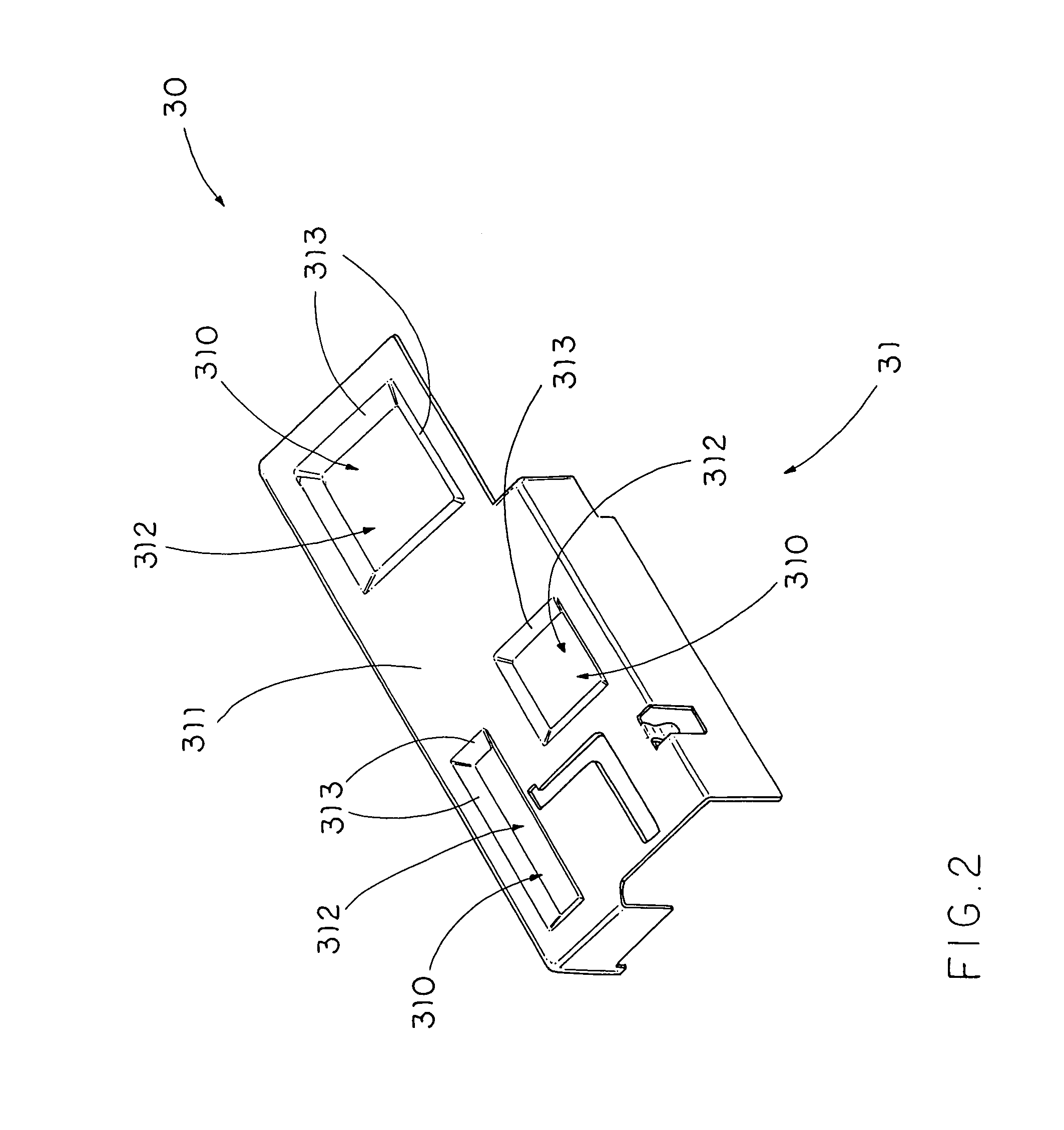

[0024]The power adapter further comprises a heat sink device 30 which comprises a heat dispersing member 31 supported within the sealing chamber 12 at a position between the enclosing wall 11 and the power transforming unit 20 to thermal-communicate with the power transforming unit 20, wherein the heat dispersing member 31 has an air insulating cavity 310 formed above the power transforming unit 20 in such a manner that when the power transforming unit 20 generates heat for heating up air within the air insulating cavity 310, the heat is diffused throughout the air insulating cavity 310 so as to e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com