Furthermore, use of the patent achieves a suitable solution for a hovering body due to for the significant reduction of its weight and phasing out dimensions of the mechanism for optional control of direction and / or position of the hovering body by the fact that the basic jacket is connected via its internal surface to the source of

liquid pressure with the compression coefficient being at least 1.1. Even greater enhancement of the efficiency of the mechanism for optional control of direction and / or position of hovering motion of the hovering body, according to the invention taking into account the contemplated characteristics of its

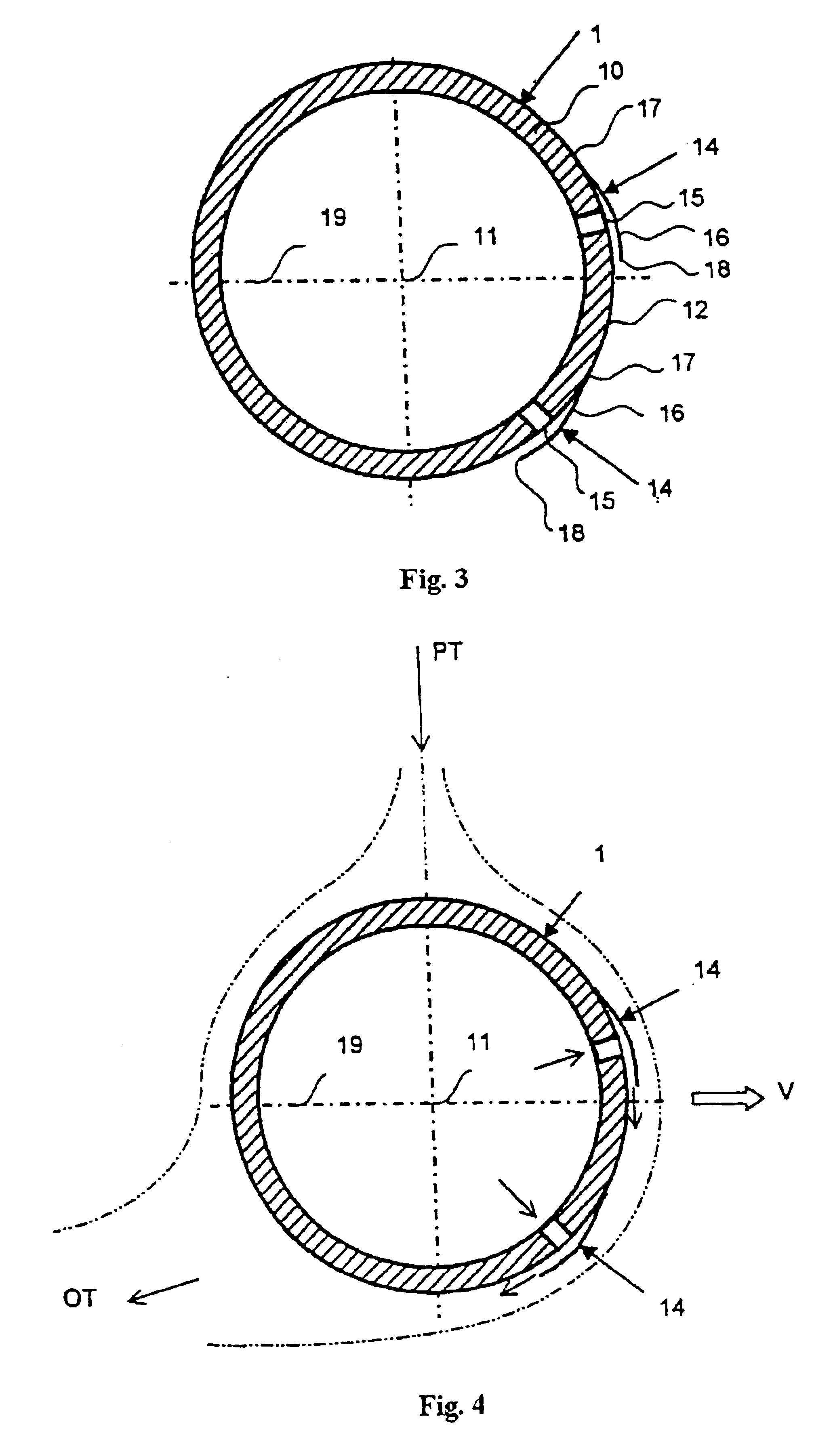

system of operation, was achieved by the fact that the basic jacket is equipped with two slot jets arranged in tangential direction of the external surface of the basic jacket in the angular spacing in the range of 20° to 80°. Another significant improvement of the complex operational possibilities of the hovering body according to the invention was achieved specifically by the fact that the basic jacket is connected to a mechanism for optional stabilisation of direction and / or position of the hovering motion, said mechanism being carried out in the shape of an elongated jacket made as a closed jacket profile, where the elongated jacket has attached thereto at least one uplift component whose boarder

attack passes into the outer surface of the elongated jacket in the chief horizontal plane of symmetry of the basic jacket_by the joint curve of the inflection points of contact of the uplift component in which the uplift component (24) has a convex or

concave surface and in the unrolled shape of the uplift component into the chief horizontal plane of symmetry of the basic jacket (1) the ratio of the longitudinal dimension of the boarder

attack to the longitudinal dimension of the end place (26) is superior to one, and the mean curve of the transverse profiles projected onto the normal plane according to the main horizontal plane of symmetry of the basic jacket, it forms an arc where the angle of its tangent at the level of the boarder

attack differs from the angle of the tangent at the level of the outlet edge of the uplift component.

Furthermore, the invention offers a suitable solution for a hovering body for a significant reduction of its weight as well as phasing out dimension of the mechanism for optional control of direction and / or position by the fact that the basic jacket together with the longitudinal jacket forms an integral unit. Thus, the solution according to this invention achieves even better results of the aforesaid hovering body, according to the invention, by the fact that the end place of the uplift component is arranged at a distance from the external surface of the longitudinal jacket. Moreover, the invention achieves a possible suitable solution for a hovering body due to the demonstrable improvement of parameters of its operational properties, as well as functional reliability, by the fact that the end place of the uplift component is arranged in contact with the external surface of the longitudinal jacket, which is at a distance from the point of contact between the boarder attack of the uplift component and the external surface of the longitudinal jacket. In this manner, a closed uplift component is created. The invention provides even further improvement of the application of the solution for a hovering body, including the aspects of acquisition cost, economy,

operational reliability, and functional service life by the fact that at least one of the uplift components is equipped with a multi-directional reactive jet interconnected with the inner space of the basic jacket for controlled ejection of liquid from the internal environment of the basic jacket into a free liquid environment.

The advantages of constructing the hovering body according to the invention can be seen especially in the fact that, as well as maintaining the properties of current known comparable solutions, its concept for creating the mechanism for optional control of direction and / or position of hovering motion of the proposed hovering body is simple as it is set in motion by its autonomous drive, which is in the form of a carrying rotor. The mechanism for optional control of direction and / or position of the hovering motion of the hovering body according to the invention represents a very efficient construction framework, which by its technically simple and economically undemanding technical means provides for achieving all the required operational properties of a hovering body, especially a helicopter, in the operational regime for a stable position, e.g. in the operational regime when a helicopter hovers in place, as well as in all the operational regimes of

dynamic motion. Due to a higher fall in the pressure gradient in comparison with current known low-pressure systems we can achieve, at the level of the outlet edge of the cover of slot jet, a significantly higher relative average speed in an arbitrary point of Coand's flow, as it is more turbulent than the equivalent level of turbulence of existing Coand's flow systems, which can be considered a significant

advantage of the solution of a hovering body according to the invention.

The value of the absolute speed of Coand's flow remains clearly subsonic. Higher energy potential of Coand's flow allows for achieving a markedly higher real bending polarisation of the flow of liquid in the surroundings of the basic jacket of the mechanism for optional control of direction and / or position of the hovering motion of the hovering body according to the invention as well as reaching a higher coefficient of equivalent

buoyancy, which enables creation of such a mechanism for optional control of direction and / or position of the hovering body according to this invention with significantly lower phasing out dimensions and, therefore, also significantly lower weight. Hence, the hovering body according to the invention, with regard to the concrete proposed conditions of its optimal operation in service, can advantageously use a whole range of possibilities of variation of quantity, its own creation and disposition arrangement of the said slot jets and their correspondent vents or covers moulded in the basic jacket of the mechanism for optional control of direction and / or position of the hovering body, where yet more possible ways of creating of a hovering body according to the invention with regard to its concrete proposed conditions of operation and due awareness of the given physical properties of the surrounding liquid environment, there are still a whole range of variations of solutions for a mechanism for optional stabilisation of direction and / or position of the hovering motion, especially with regard to the number, shape and mutual dispositional arrangement of uplift components, concretely manifested, where all the variations of creating a hovering body according to the invention can be appropriately and advantageously constructed, even with regard to the optimisation of its operational properties as far as the lowest level of acquisition costs as well as the extreme technological standards of its real production and achievement of the highest possible

operational reliability and functional service life, while fulfilling guaranteed and fault-free requisite functions of the hovering body in any

system of operation of hovering which is undoubtedly assisted by such a formation of its elongated jacket, where at least one of the uplift components is equipped with a multi-directional jet for controlled ejection of liquid from the internal environment of the basic jacket, which is integrally connected to the elongated jacket, into a free liquid environment.

Login to View More

Login to View More  Login to View More

Login to View More