Concentrator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

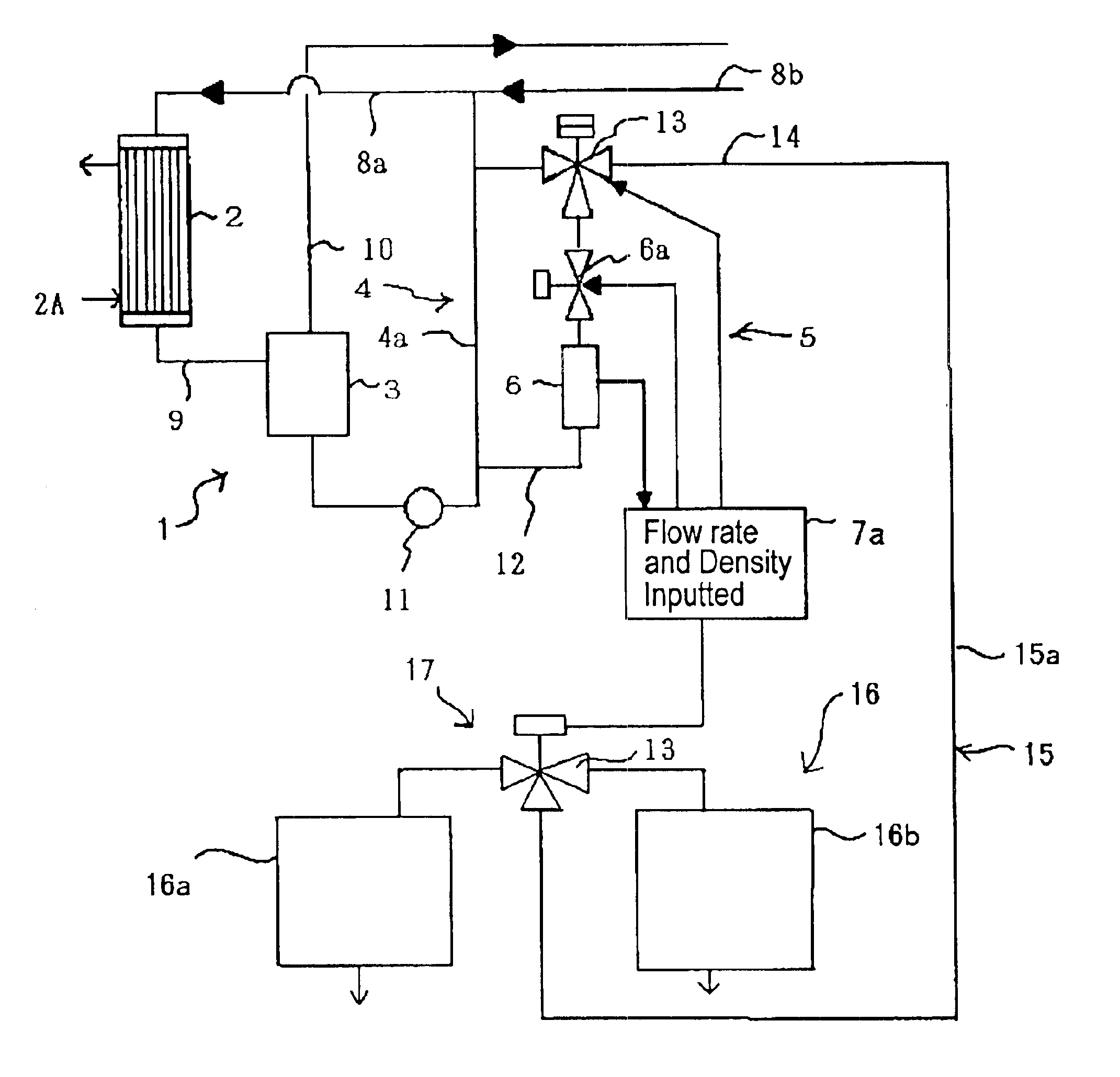

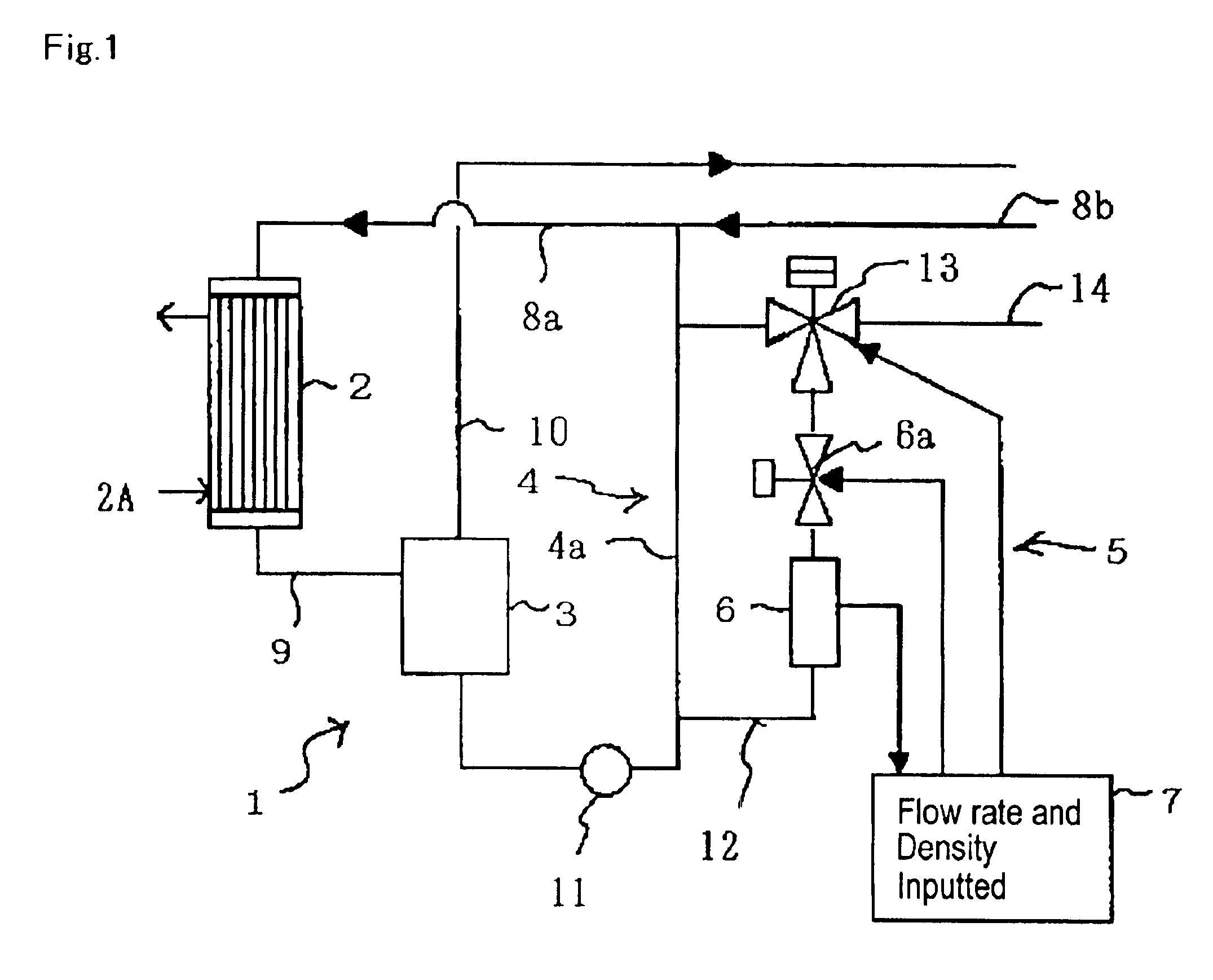

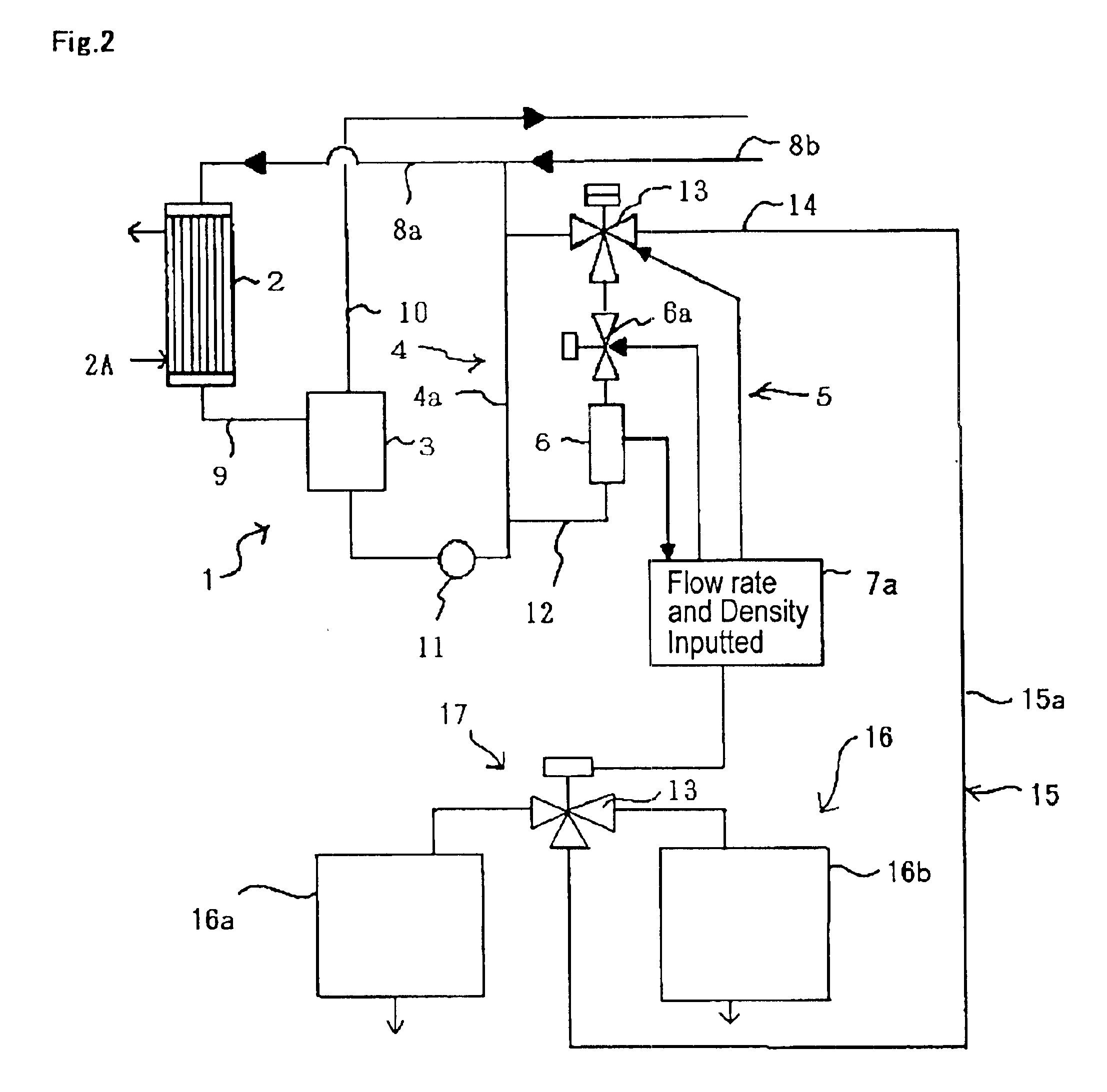

FIG. 1 is a schematic illustration of a concentrator that is an embodiment of this invention. As shown in FIG. 1, the concentrator (1) of this invention comprises a heater (2), a gas-liquid separator (3), a returning device (4), a liquid draw-out device (5), a concentration detector (6) and a controller (7).

Heater 2 is designed so as to heat a mixture of an extract or raffinate that is fed from a simulated moving bed chromatographic apparatus (not shown) and which may be called a feedstock hereinafter, with a liquid that is a concentrated liquid forcibly returned with returning device 4, to evaporate a portion of the mixture. Heating is carried out with heating means 2A that is capable of heating the mixture to above its boiling point under the operation pressure. When heater 2 is a forced-circulation falling film evaporator, a shell-and-tube exchanger of long-tube vertical type is employed for heating means 2A.

For this function, the top part of heater 2 is connected with feedstock ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Flow rate | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com