Tool belt with spaced receiver blocks selectively receiving both complimentary tool holders and tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

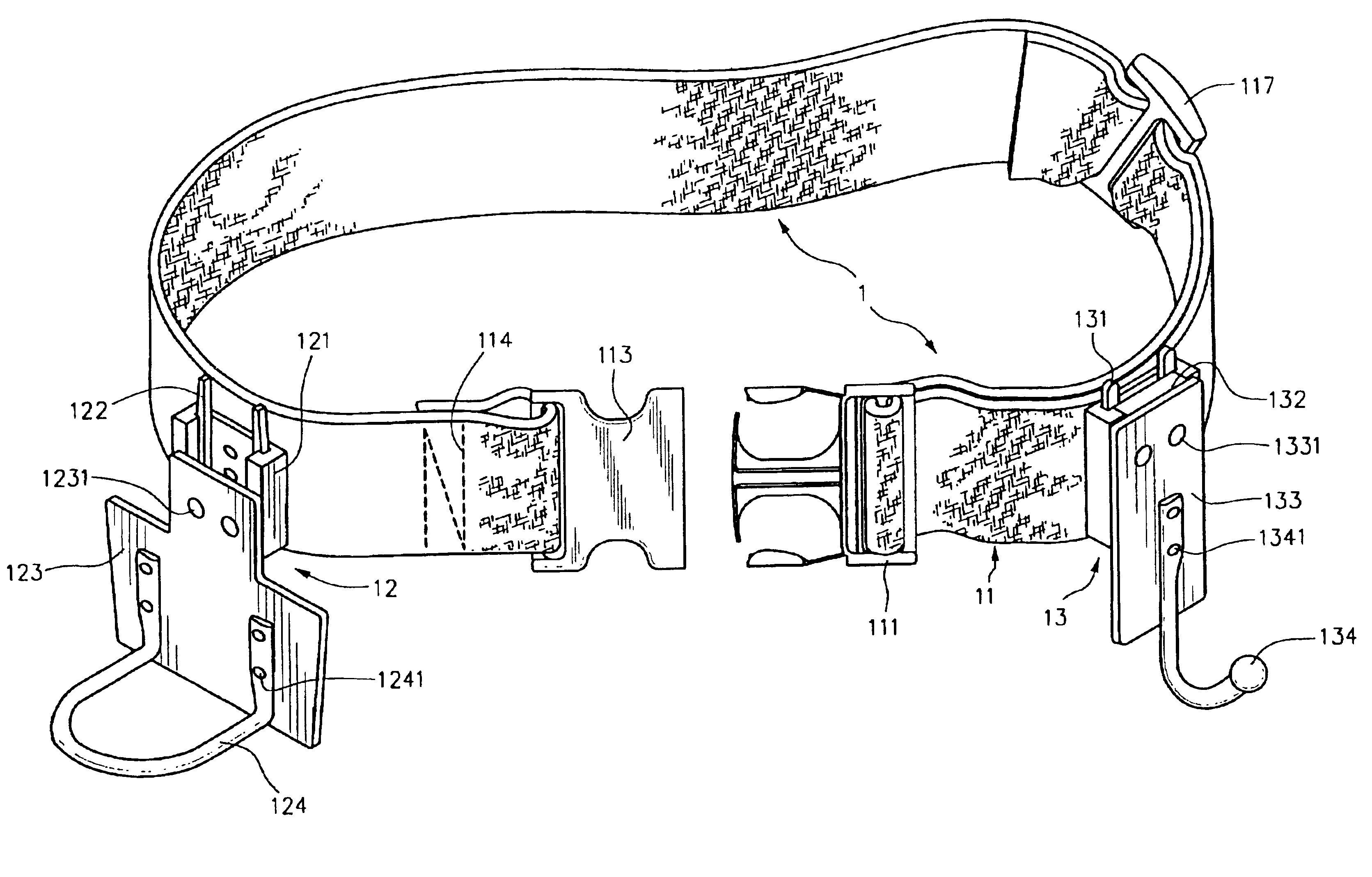

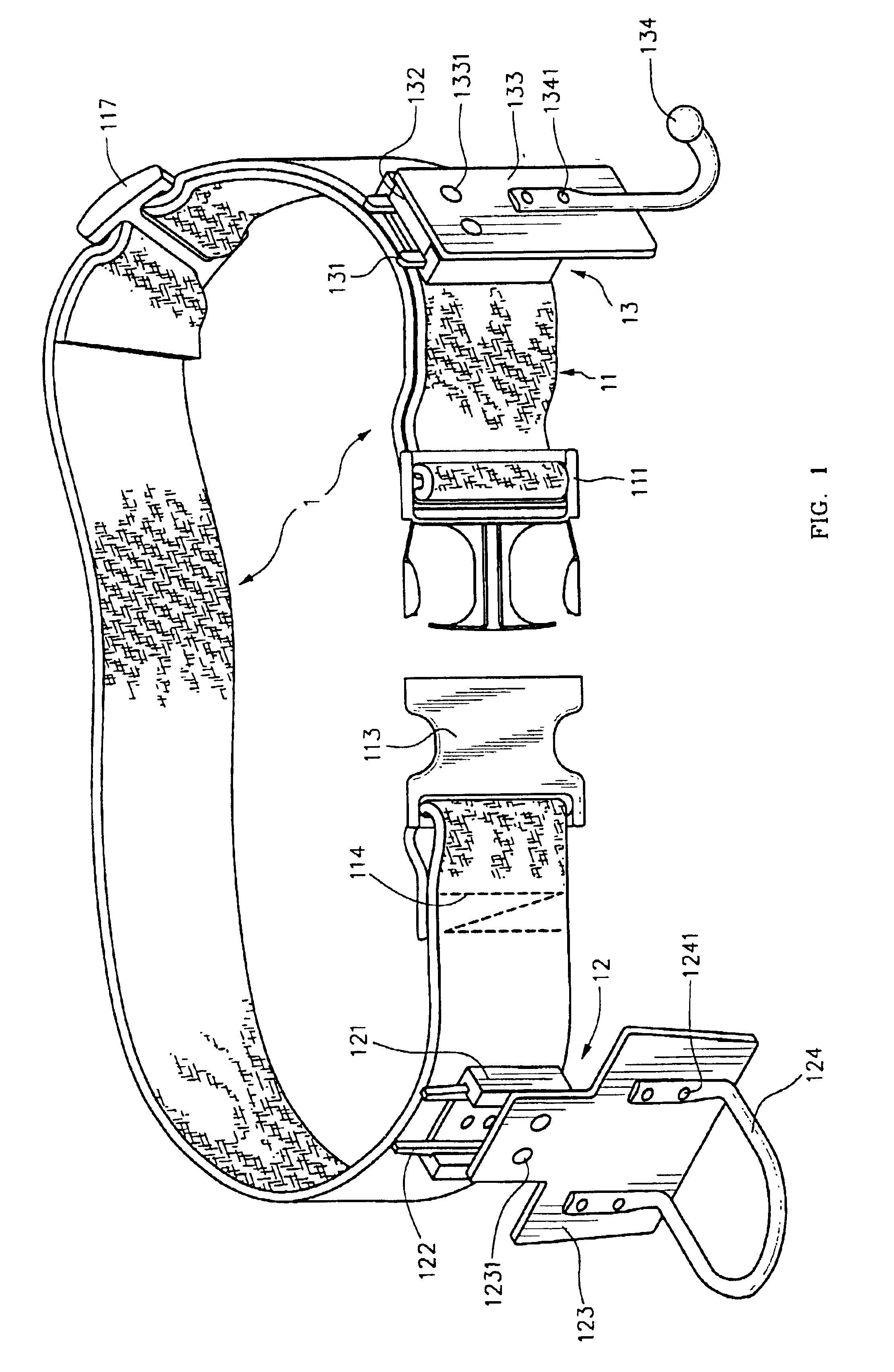

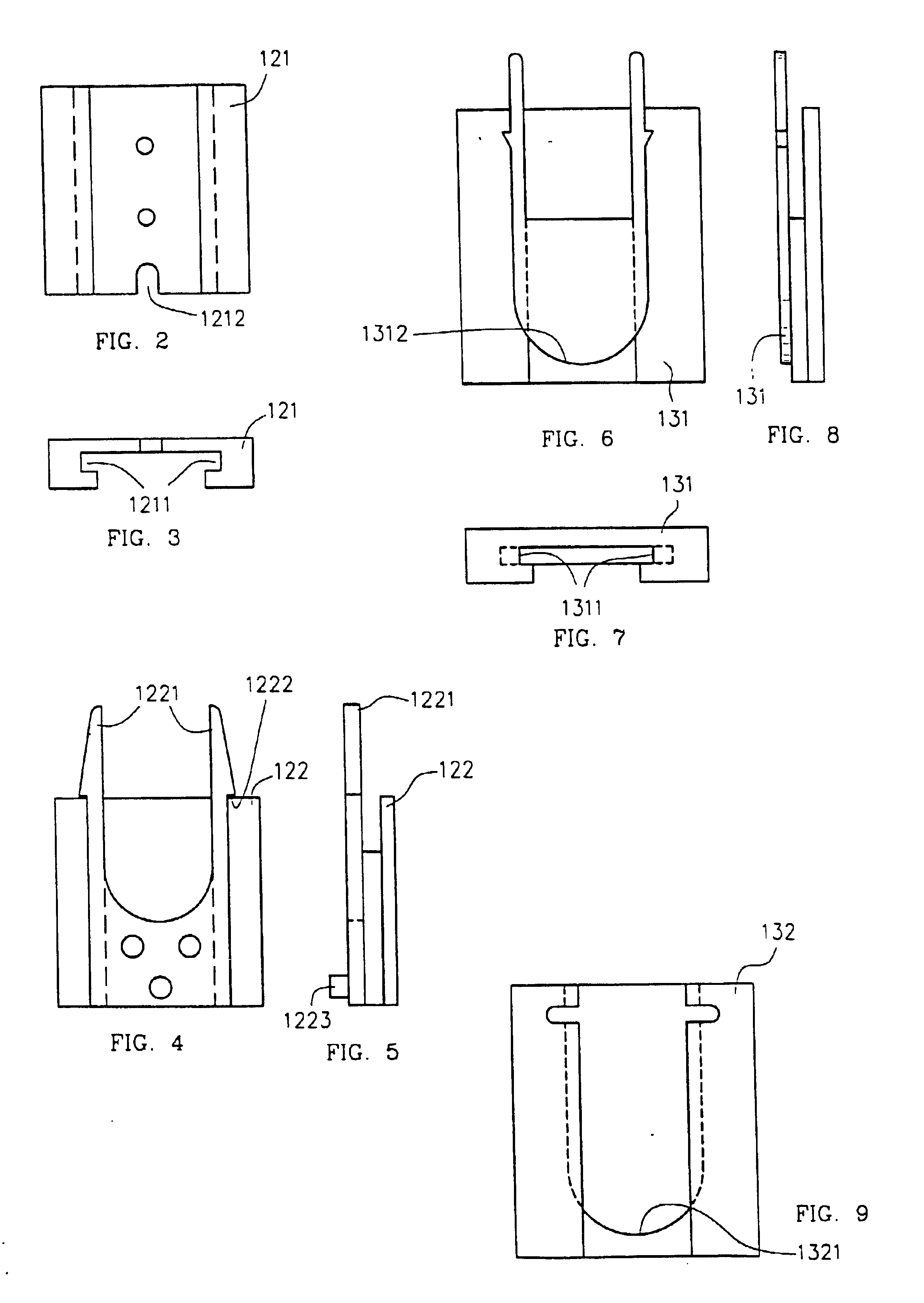

[0088]FIG. 3 is a bottom plan view of a preferred first embodiment of a receiver block that is used in, and part of, the tool belt system in accordance with the present invention previously seen in FIG. 1.

[0089]FIG. 4 is a front plan view, and

[0090]FIG. 5 is a side plan view, of a preferred first embodiment of an attaching block, suitably removably mounted to the first embodiment receiver block shown in FIGS. 2 and 3, that is used in, and part of, the tool belt system in accordance with the present invention previously seen in FIG. 1.

[0091]FIG. 6 is a front plan view,

[0092]FIG. 7 is a top plan view, and

second embodiment

[0093]FIG. 8 is a side plan view of a preferred second embodiment of a receiver block used in, and part of, the tool belt system in accordance with the present invention previously seen in FIG. 1.

[0094]FIG. 9 is a front plan view of a preferred second embodiment of an attaching block, suitably removably mounted to the second embodiment receiver block shown in FIGS. 6 through 8, used in, and part of, the tool belt system in accordance with the present invention previously seen in FIG. 1.

[0095]FIG. 10 is a perspective view of a tool affixing the attaching block previously seen in FIGS. 4 and 5.

[0096]FIG. 11 is a perspective view of a container affixing the attaching block previously seen in FIGS. 4 and 5.

[0097]FIG. 12 is a perspective view of a power tool affixing the attaching block previously seen in FIGS. 4 and 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com