MEMS structure with raised electrodes

a technology of raised electrodes and membranes, applied in the field of electrochemical components and structures, can solve the problems prone to drift of surface potentials on dielectric surfaces, repeatability of positioning, etc., and achieve the effect of mitigating the effect of uncontrollable dielectric surface potentials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

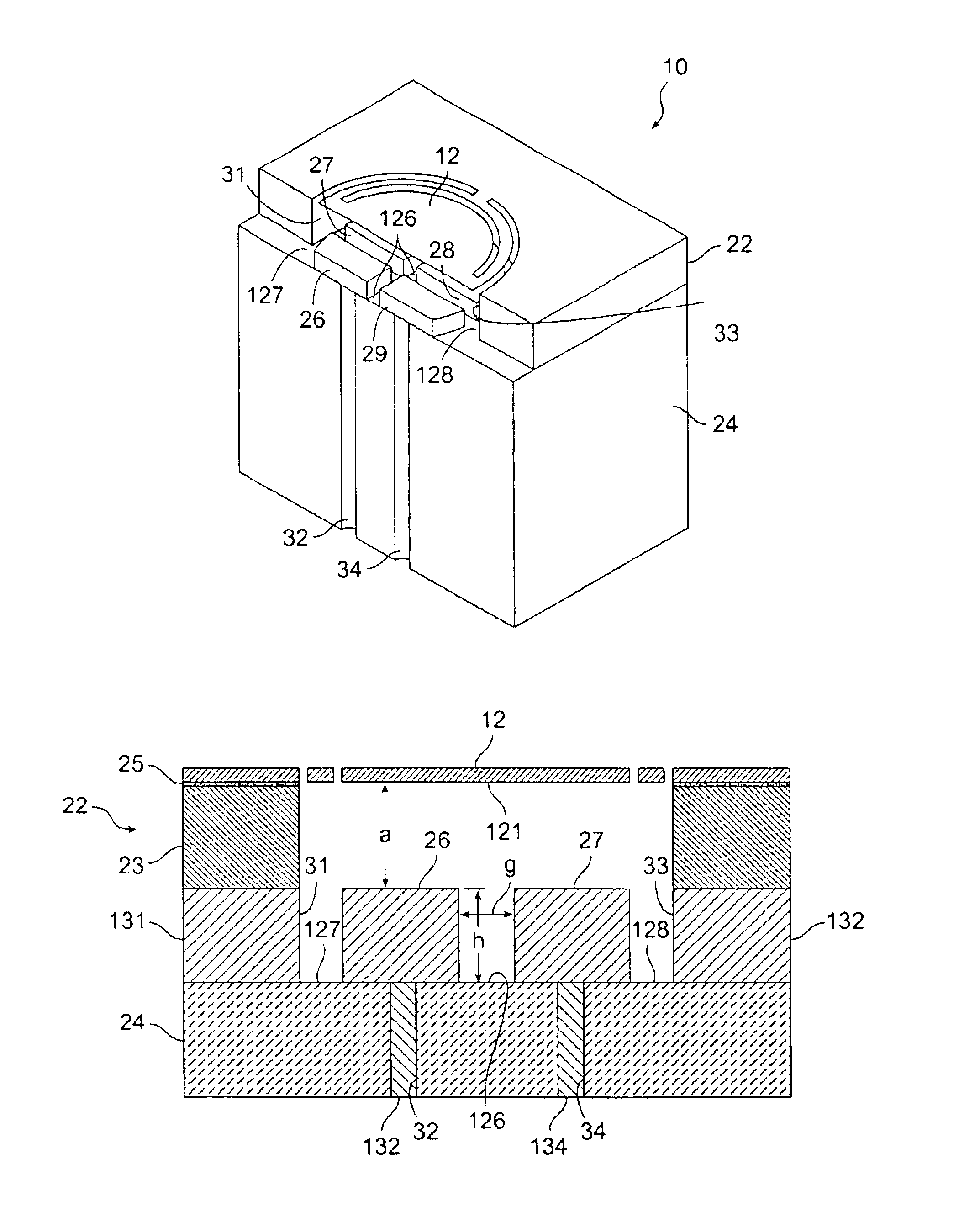

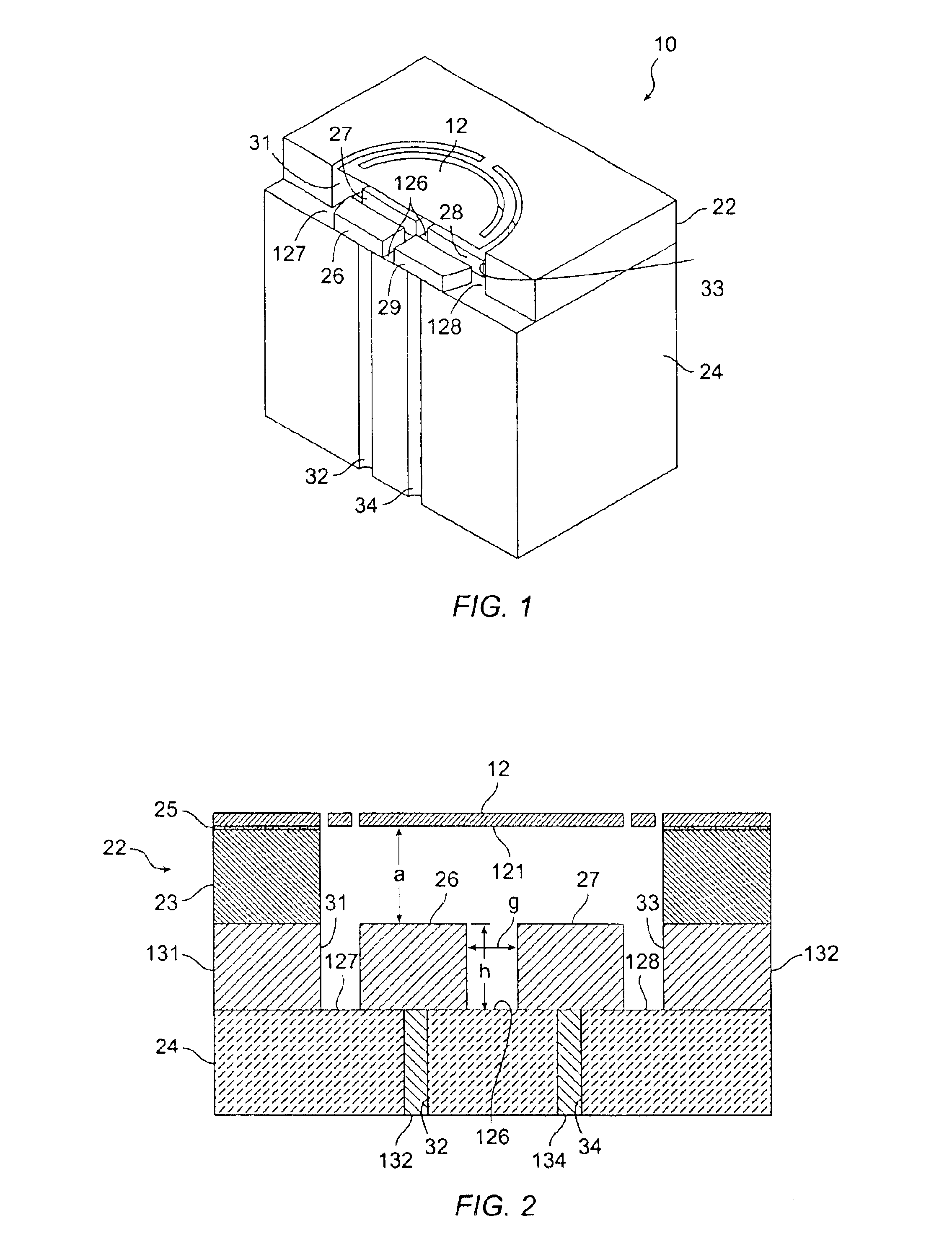

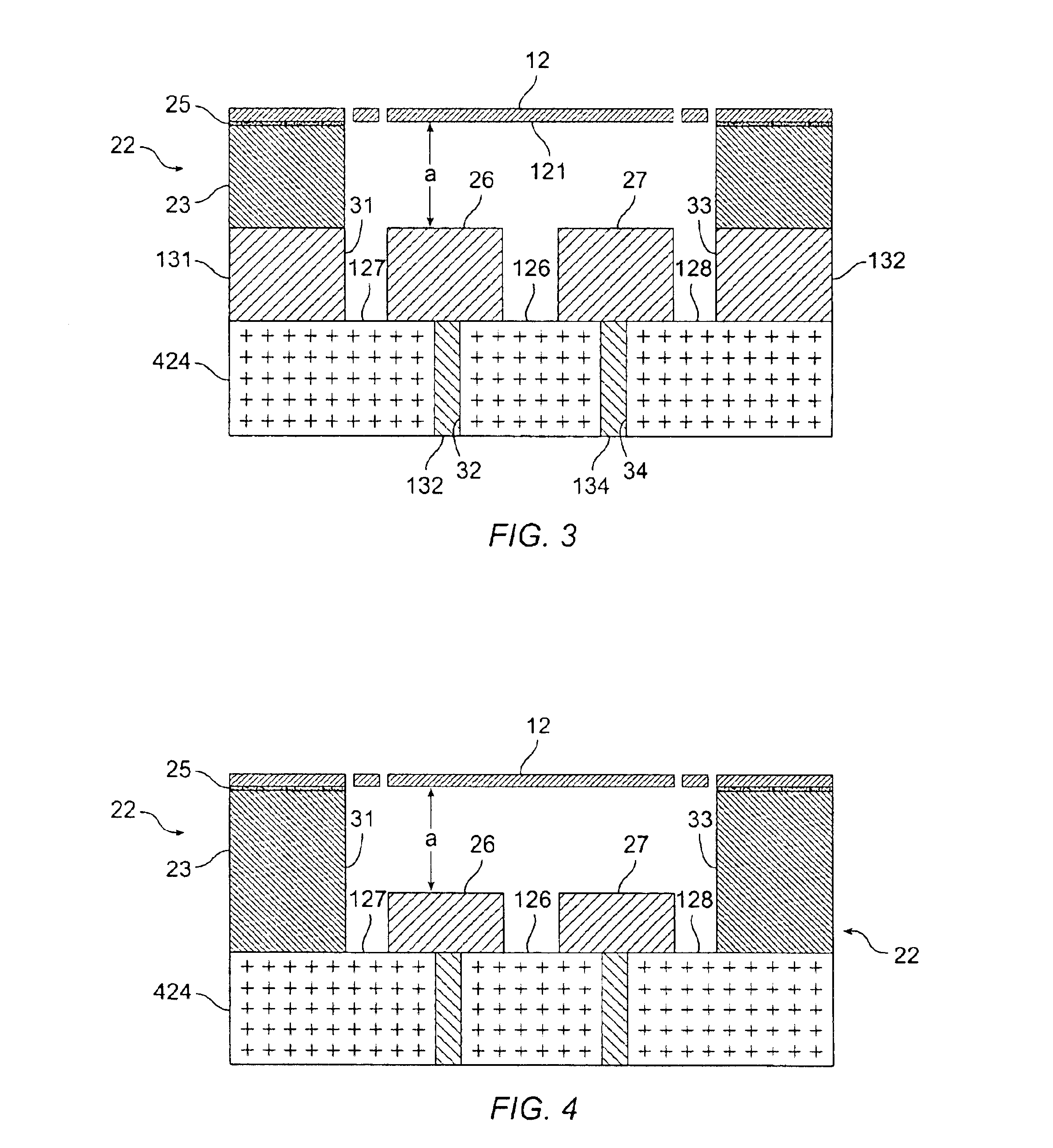

Reference is made to FIG. 1 in which is shown a single MEMS (Micro Electro-Mechanical Systems) array element 10 according to the invention, with a MEMS-based mirror 12 fabricated in an integrated Silicon on Insulator (SOI) structure (a MEMS structure) 22 and mounted on a substrate or base 24, which is typically electrically insulative. According to the invention, and referring also to FIG. 2, a mechanism is provided whereby the effects of uncontrolled surface potentials are mitigated through use of raised electrodes 26-29 and optionally highly resistive interstitial regions 126 between the several electrodes 26-29 and interstitial regions 127, 128 between the raised electrodes 26-29 and surrounding conductive sidewalls or surfaces 31 and 33. The electrodes 26-29 are connected to voltage sources (not shown) through vias 32, 34, etc. containing a conductive material, such as a metal 132, 134. The structure of element 10 shown in FIG. 1 is not specific to a particular configuration. Va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com