Low-profile air filter module

a filter module and low-profile technology, applied in the field of filter modules, can solve the problems of large air filtration units, large installation or reinstallation of self-contained commercial air filtration units, and high cost of new configuration, and achieve the effect of greatly reducing the overall height of the filter modul

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

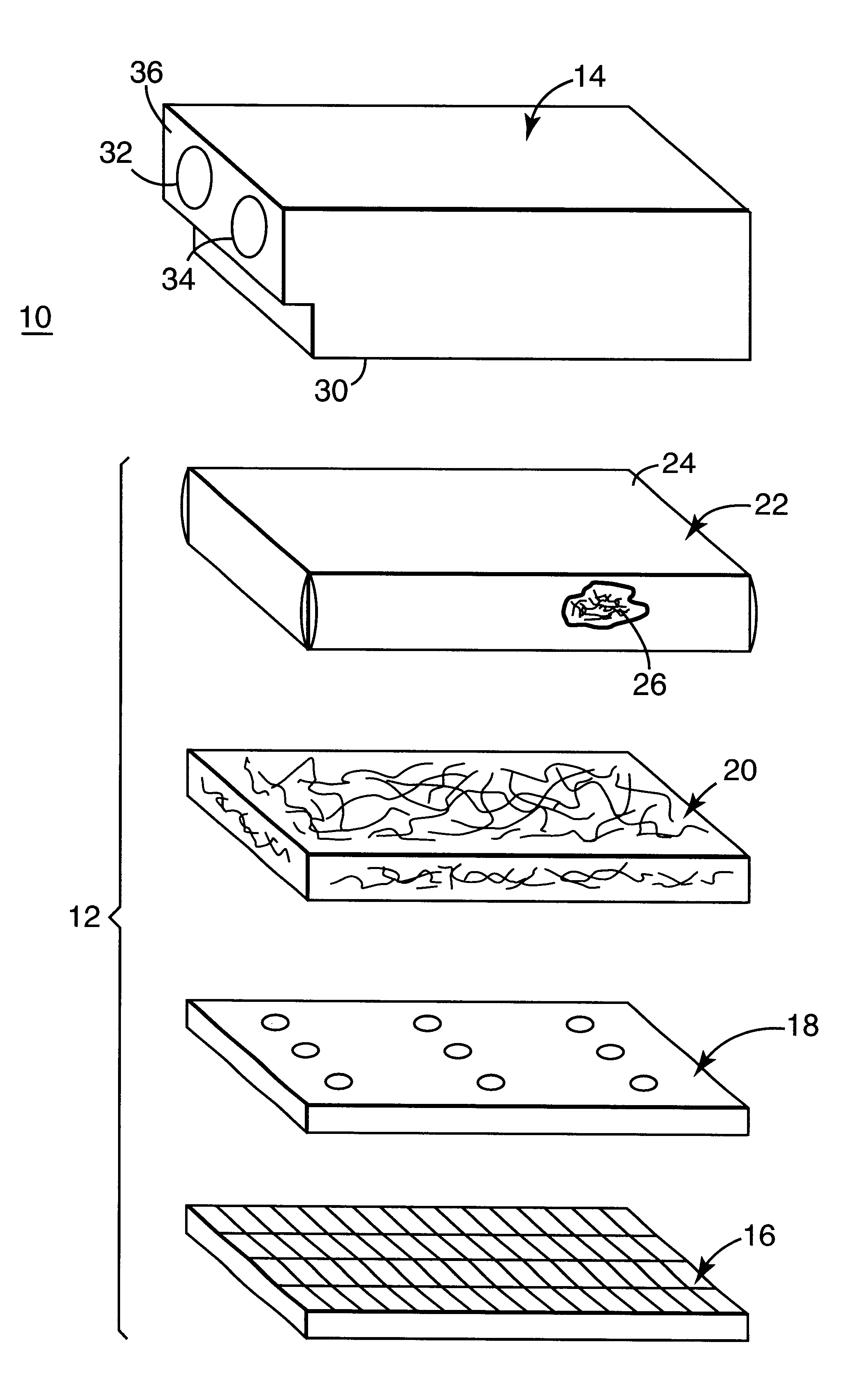

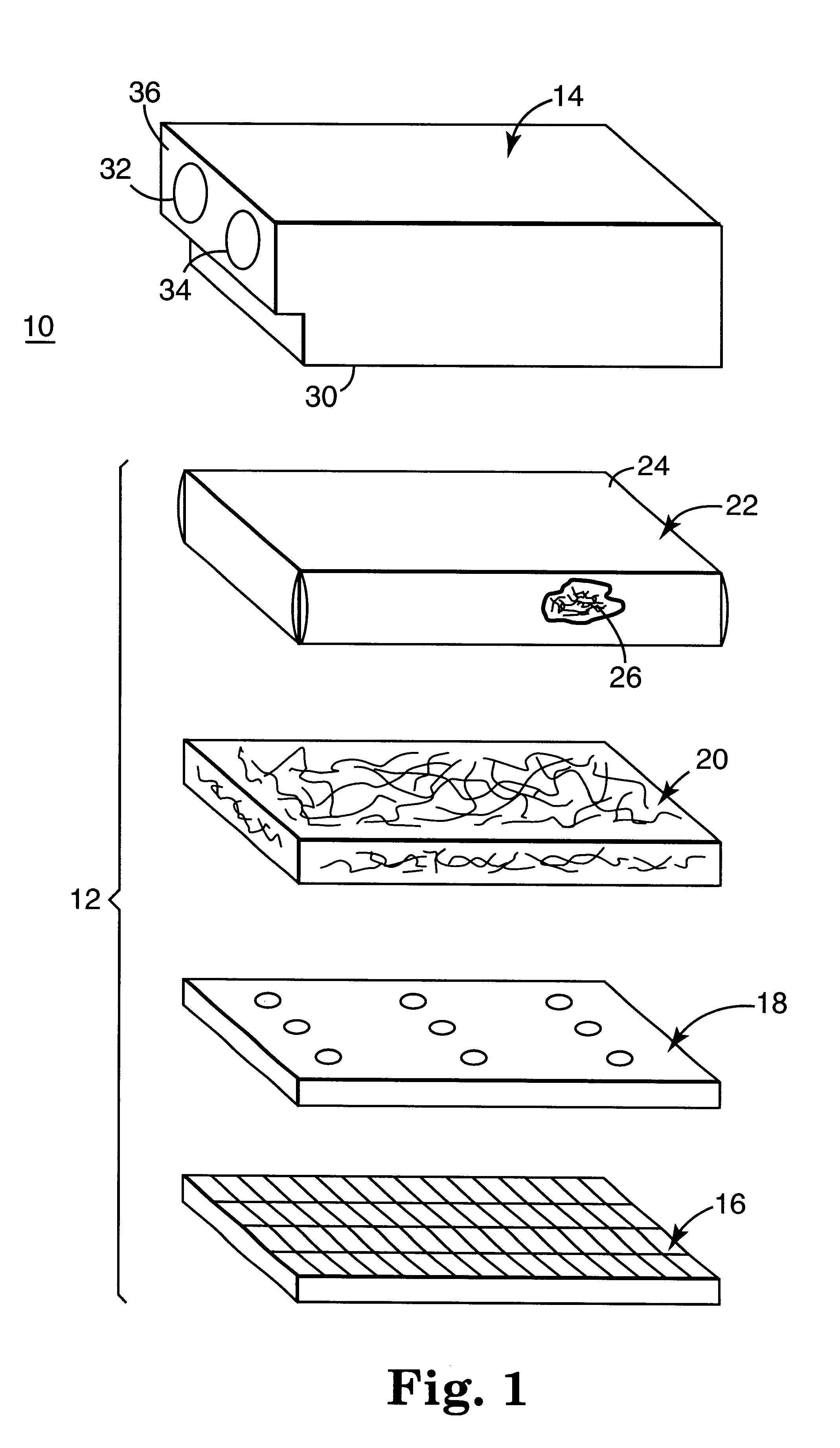

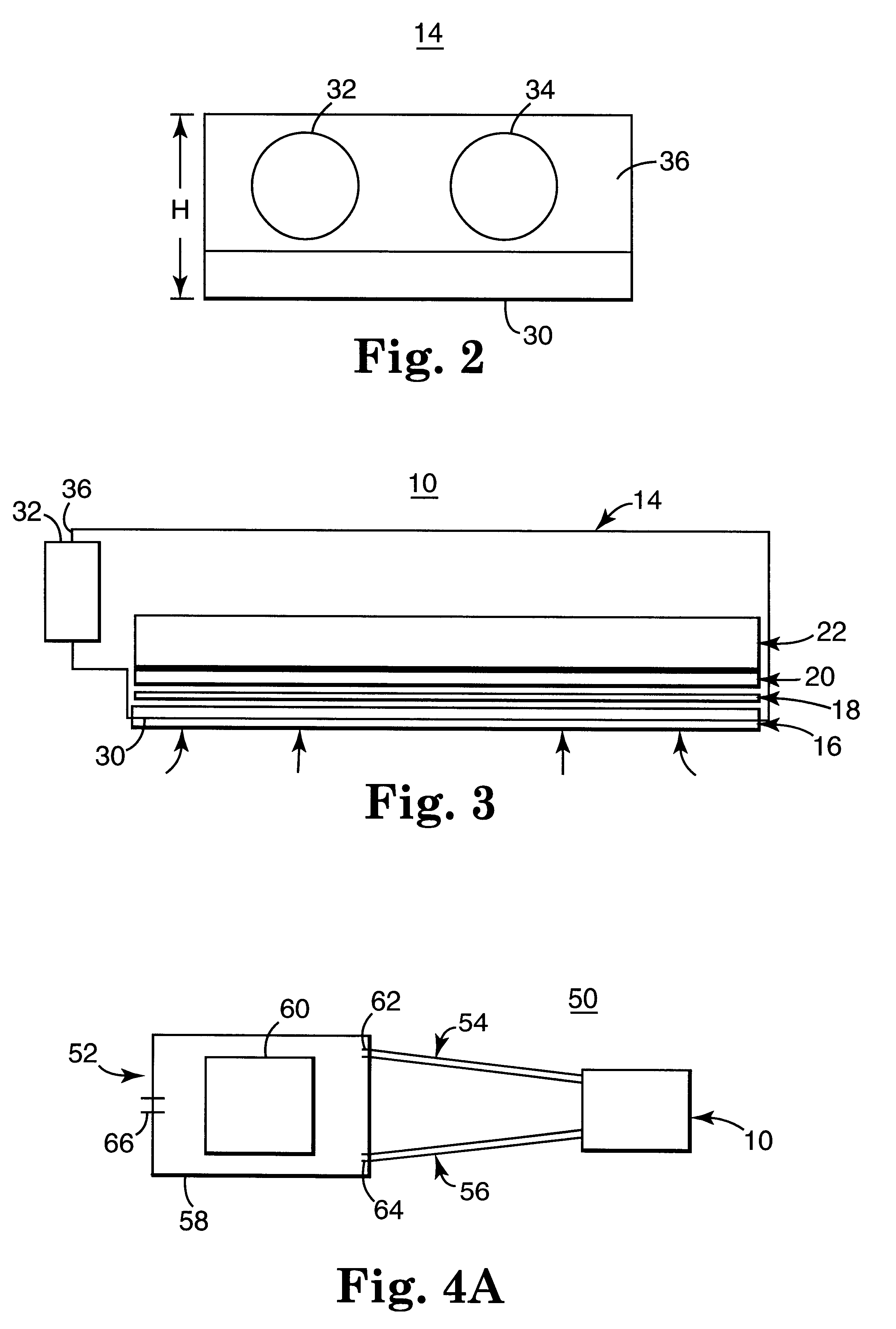

One preferred embodiment of a filter module 10 in accordance with the present invention is shown in FIG. 1. Filter module 10 includes a filter assembly 12 and a housing 14. Details on the various components are provided below. In general terms, however, housing 14 is configured to maintain filter assembly 12.

In one preferred embodiment, filter assembly 12 includes an intake grille 16, a pre-filter 18, a primary particulate filter 20 and a sorbent material filter 22. Each component of filter assembly 12 corresponds generally in size with a size of housing 14.

Grille 16 is sized to encompass a lower portion (or inlet) of housing 14. Grille 16 is preferably an egg crate grille, formed from hardened plastic, as is known in the art. Alternatively, other relatively rigid materials are equally acceptable, such as aluminum. Grille 16 is provided to capture large, air-borne fibers as well as to render filter module 10 aesthetically pleasing. In this regard, upon final assembly and installatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Mass | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com