Laser cutting method and laser cutter

a laser cutter and laser cutting technology, applied in metal-working equipment, welding equipment, manufacturing tools, etc., can solve the problems of difficult to maintain a suitable cutting quality, adversely affect the quality of the cut surface, and insufficient cutting laser energy cannot reach the inside of mild steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

the laser cutting method will be explained below.

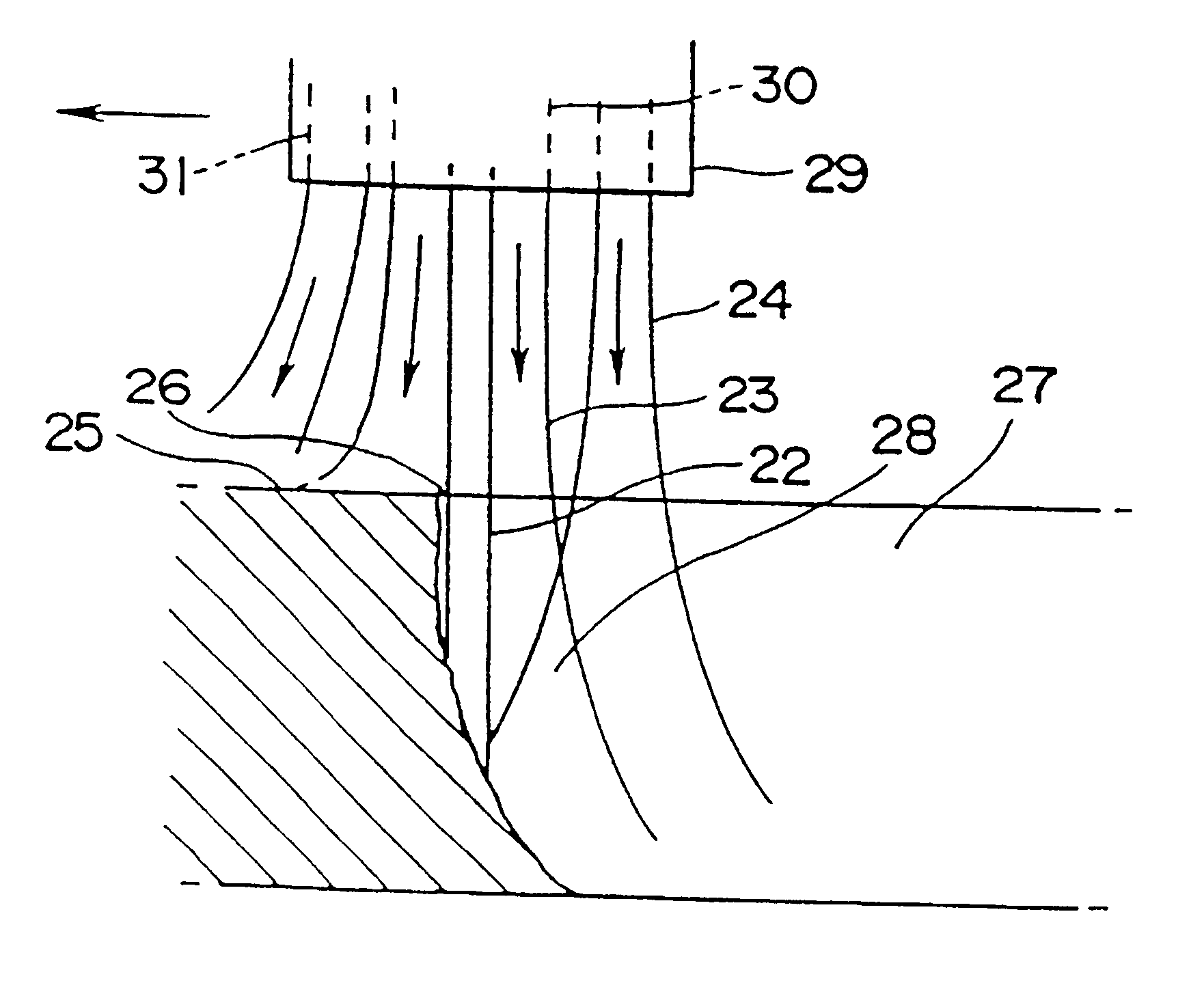

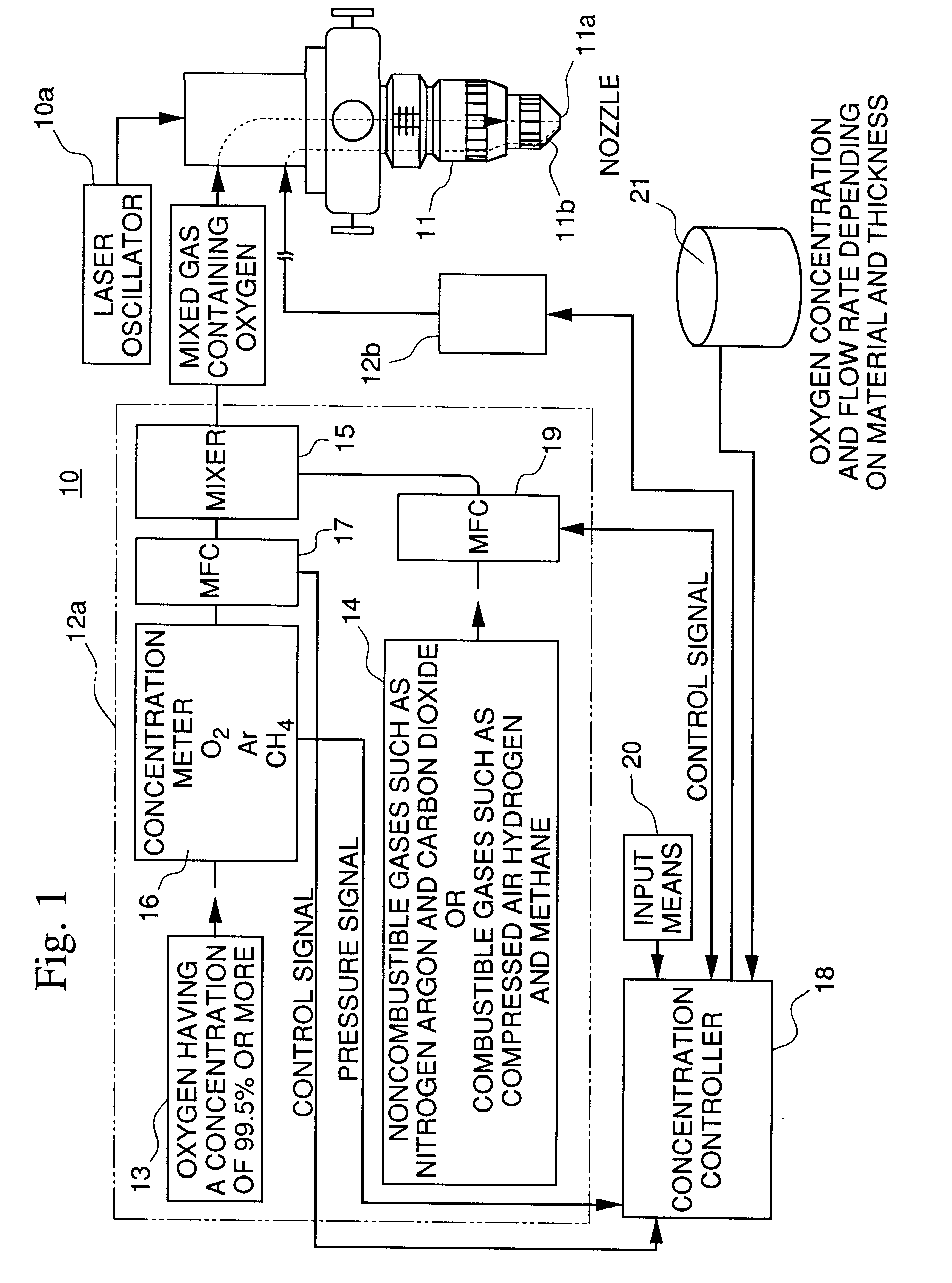

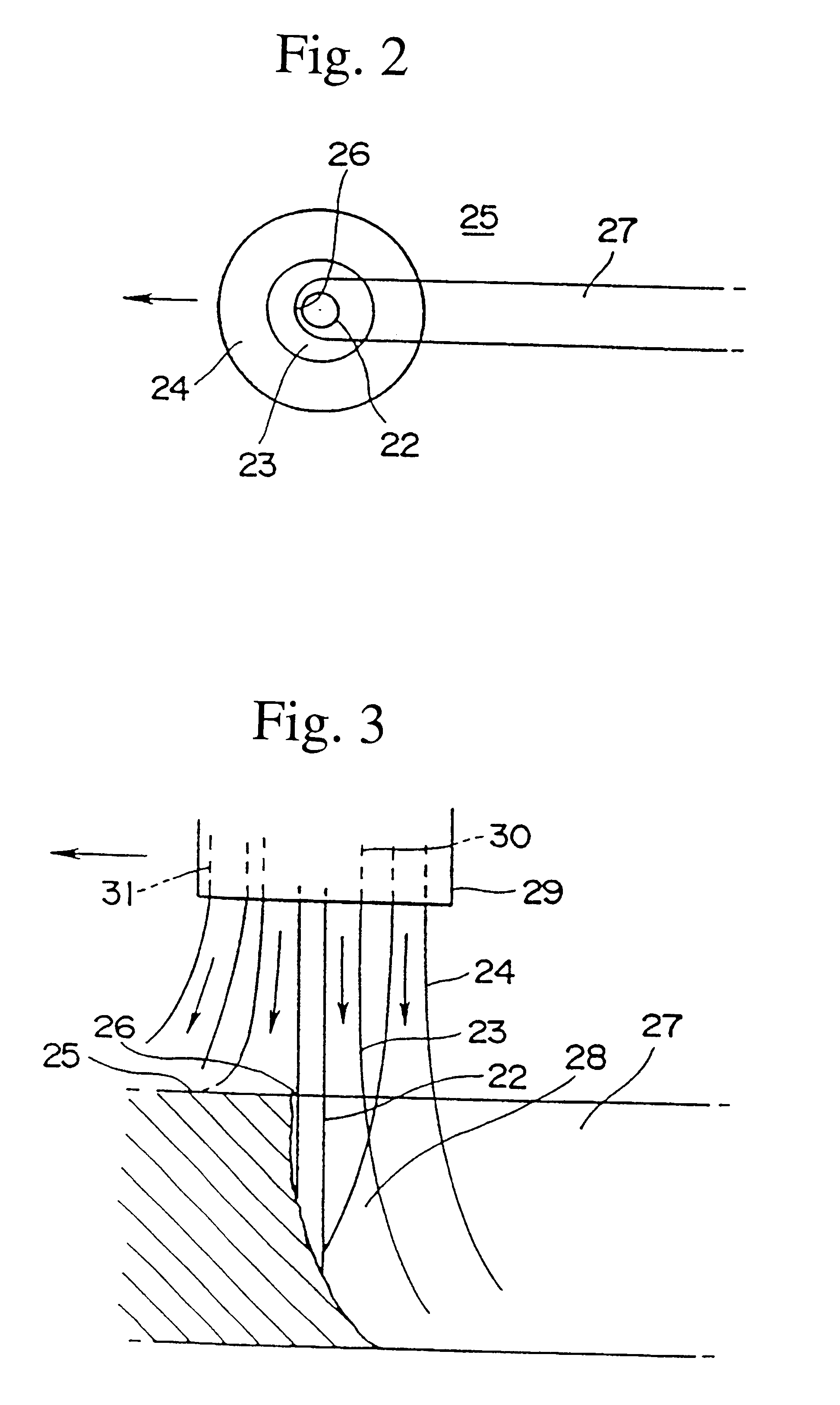

FIG. 2 is a planar view showing the co-axial double nozzle, for example, shown in FIG. 6. In FIG. 2, reference numeral 22 denotes a laser beam, reference numeral 23 denotes a gas containing oxygen at a high concentration (a concentration of 99.5% or more), reference numeral 24 denotes a gas containing oxygen at a low concentration, and reference numeral 25 denotes a material to be cut (steel plate).

The diameter of the laser beam 22 is in a range from 0.1 to 0.5 mm. The gas steam of the high concentration oxygen 23 diffuses at the area within approximately 1.5 mm of the laser beam 22. Furthermore, the gas stream of a mixed gas 24 diffuses to the area surrounding the gas stream of the high concentration oxygen 23. The mixed gas 24 comprises oxygen and the gas other than oxygen such as nitrogen. The oxygen concentration of the mixed gas 24 is lower than that of the high concentration oxygen 23.

The high concentration oxygen 23 and the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com