Cooling system for an off-highway vehicle

a technology for cooling systems and off-highway vehicles, applied in the field of motor vehicles, can solve the problems of little ram-urged air available to remove heat, engine noise and noise of cooling fans of off-highway vehicles, and achieve the effect of reducing system noise and reducing muffler back pressur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

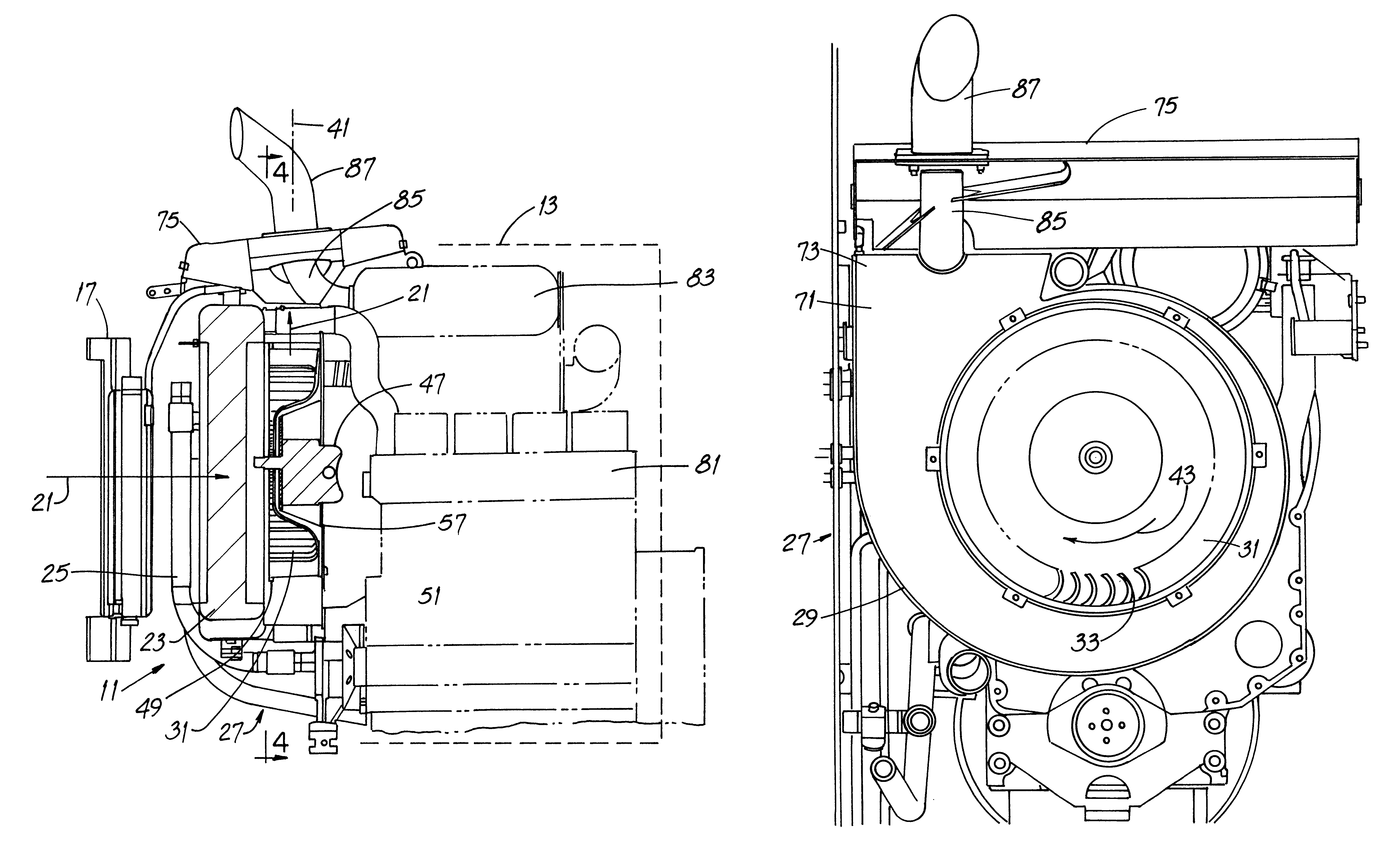

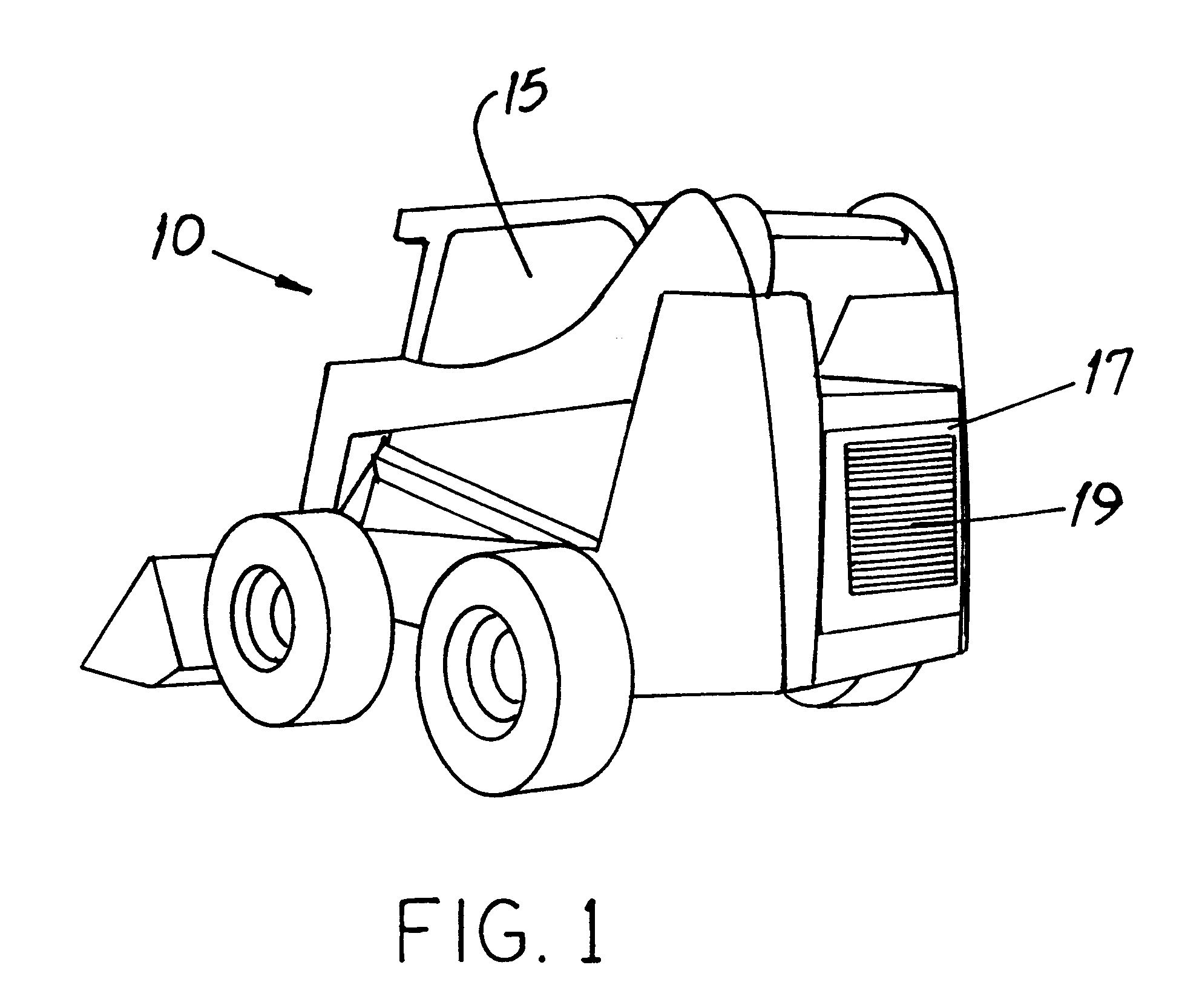

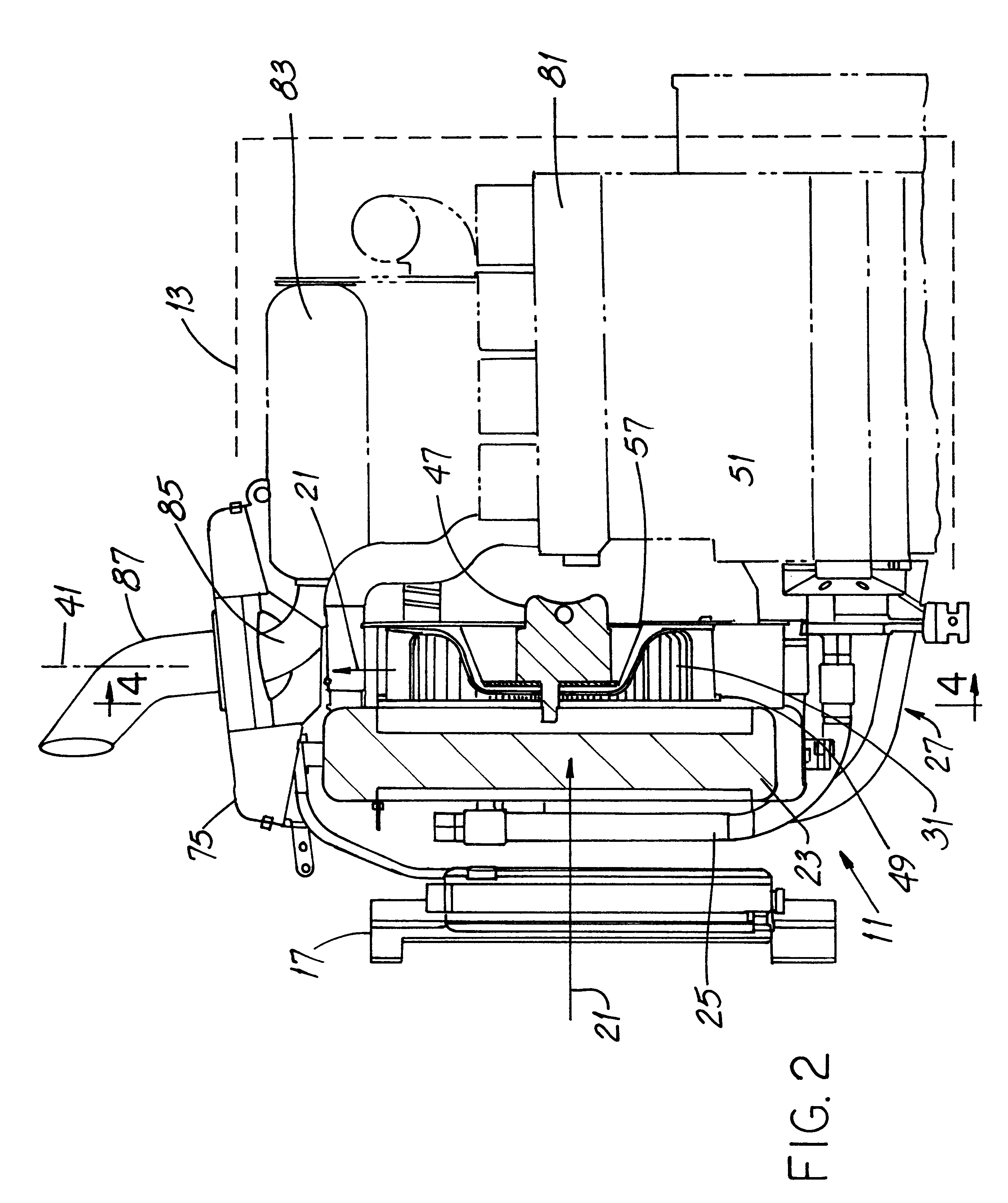

Referring first to FIGS. 1, 2 and 3, an exemplary off-highway vehicle 10 is equipped with the new cooling system 11. Such vehicle 10 is of a type known as a skid-steer front end loader. The vehicle 10 includes an engine compartment, represented by the dashed-line box 13, adjacent to the operator's compartment 15. A rear door 17 has slots 19 therethrough and such slots 19 are in air flow communication with the cooling system 11 described below. That is, the cooling air flow path 21, represented by the same-numbered arrow in FIGS. 2 and 3, is in a forward direction through the door 17. Because most off-highway vehicles (like the vehicle 10) are stationary or move at low ground speed when working, there is little or no ram-urged air in the flow path 21.

(The term "skid-steer" refers to the fact that all of the vehicle wheels are maintained perpendicular to their respective axles. Steering is effected by driving the wheels on one side of the vehicle 10 at a rotational speed which is diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com