Display module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033]The present invention provides a display module. To make the objective, the technical solution, and the effect of the present invention clearer and more explicit, the present invention will be further described in detail below with reference to the accompanying drawings. It should be understood that the specific embodiments described here are only used to explain the present invention instead of being used to limit the present invention.

[0034]The present invention aims at the technical issue that in a conventional display module, to achieve a design of a narrow bezel and an ultra-thin module, it is required to design the thickness of the reinforcement plate thinner, which results in poor adhesion and affects reliability of bending of the bonding region. The present embodiment can solve the defects.

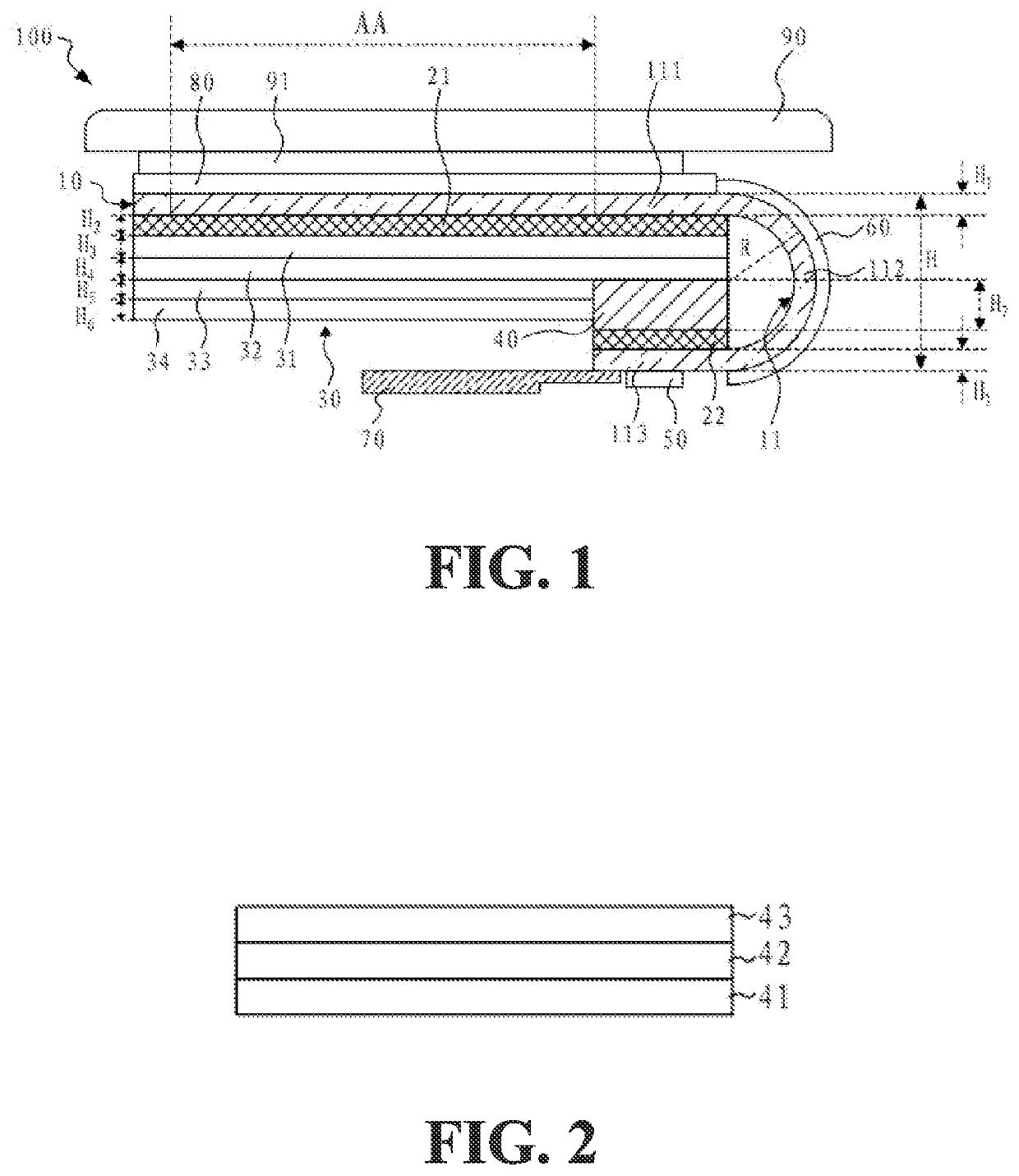

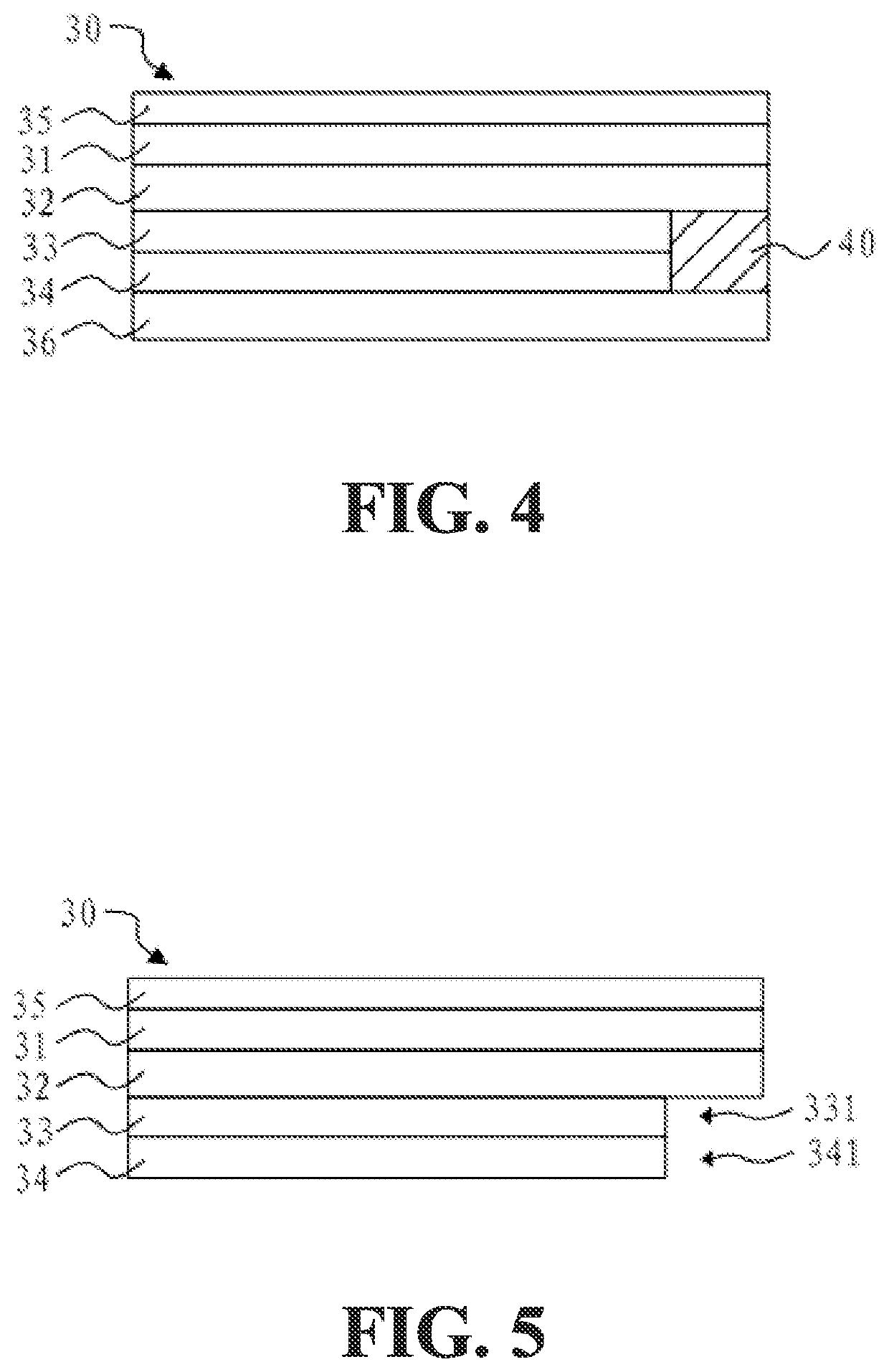

[0035]With reference to FIG. 1, an embodiment of the present invention provides a display module 100 comprising a display panel 10, a first backplate 21, a super clean foam (SCF) ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com