Vane pump

a technology of vane pump and manufacturing cost, which is applied in the direction of rotary/oscillating piston pump components, machines/engines, liquid fuel engines, etc., can solve the problems of increasing the number of man-hours and the increase of the manufacturing cost of the apparatus having the vane pump, and achieve the effect of reducing the manufacturing cost of the apparatus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

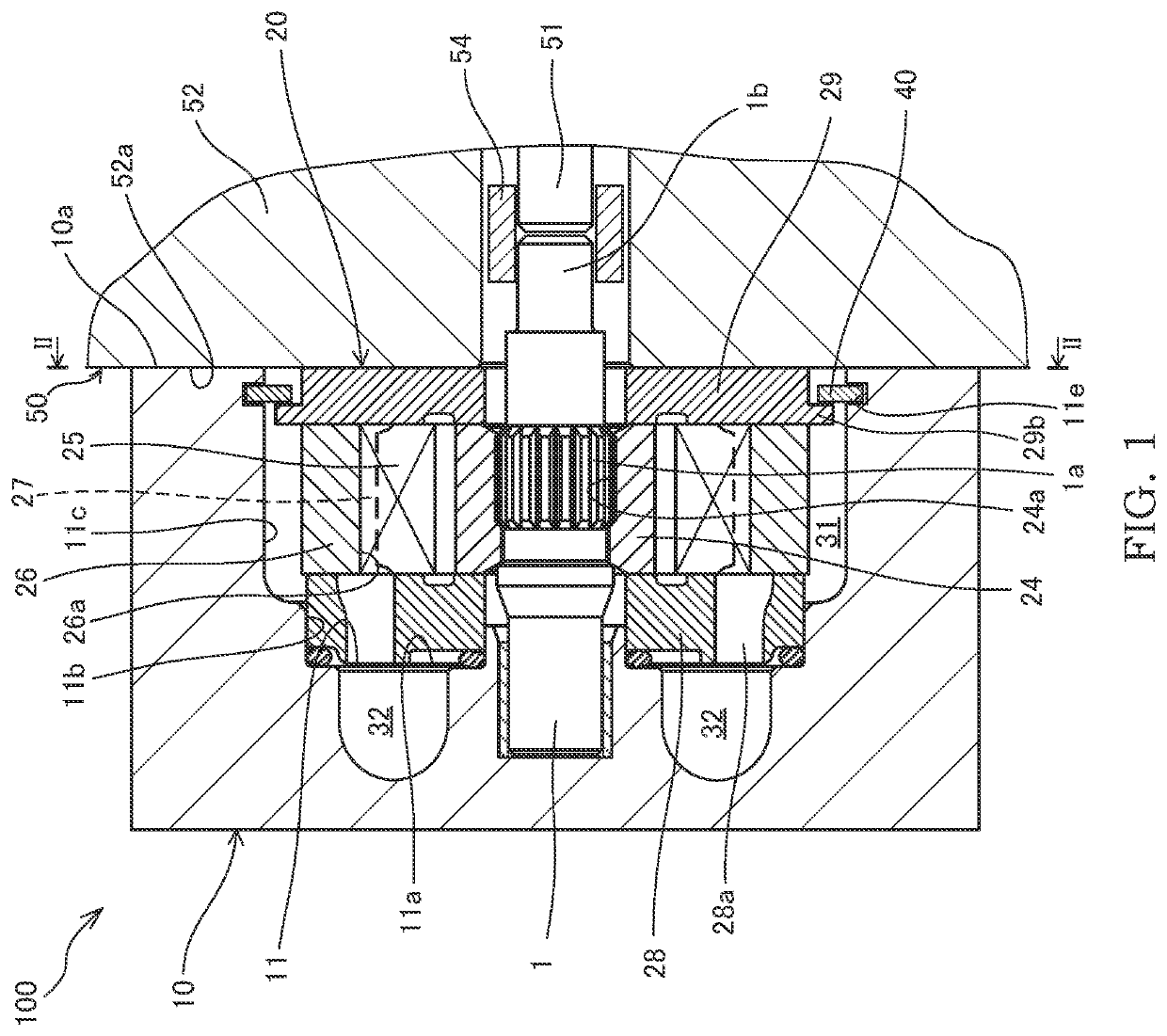

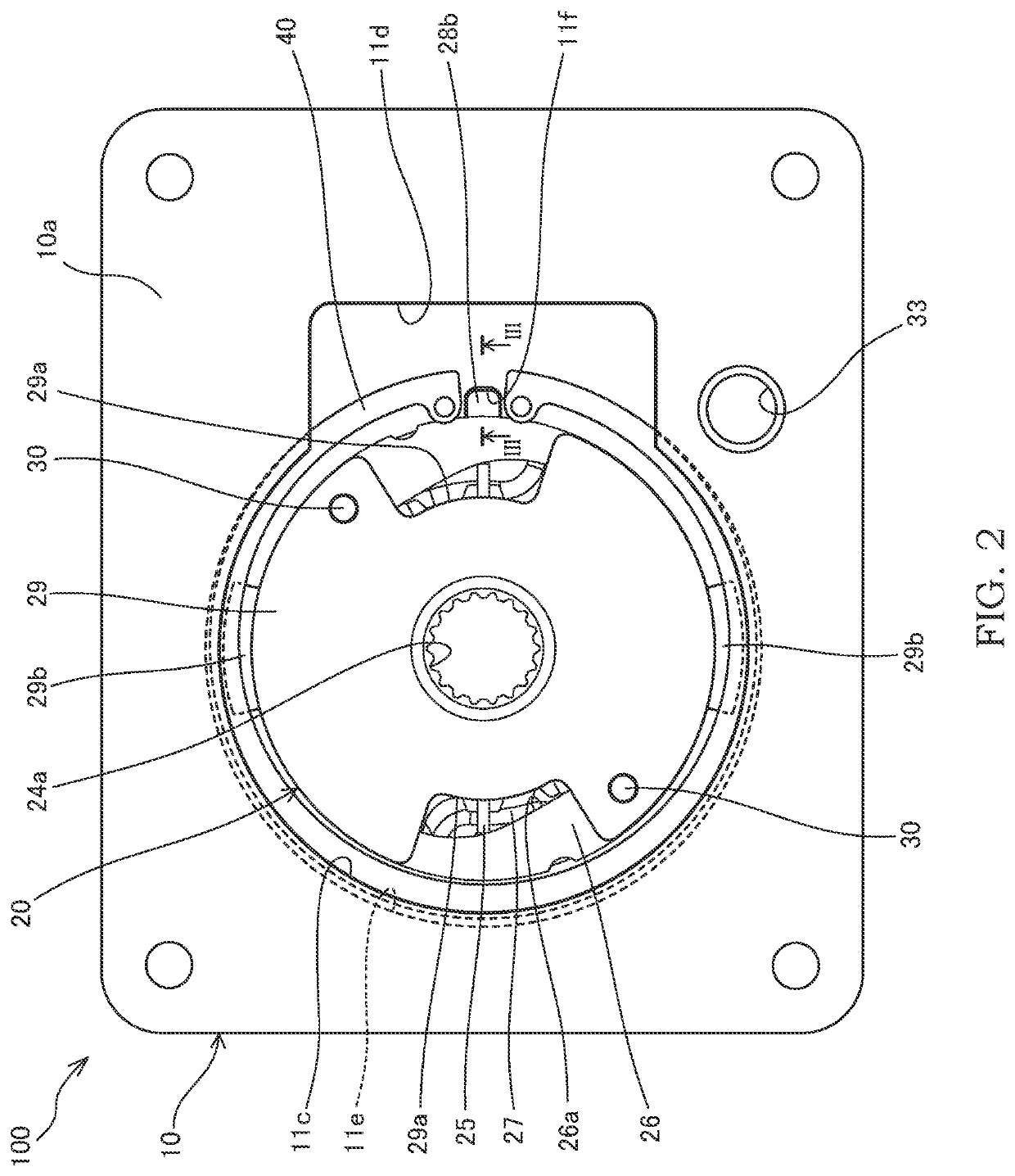

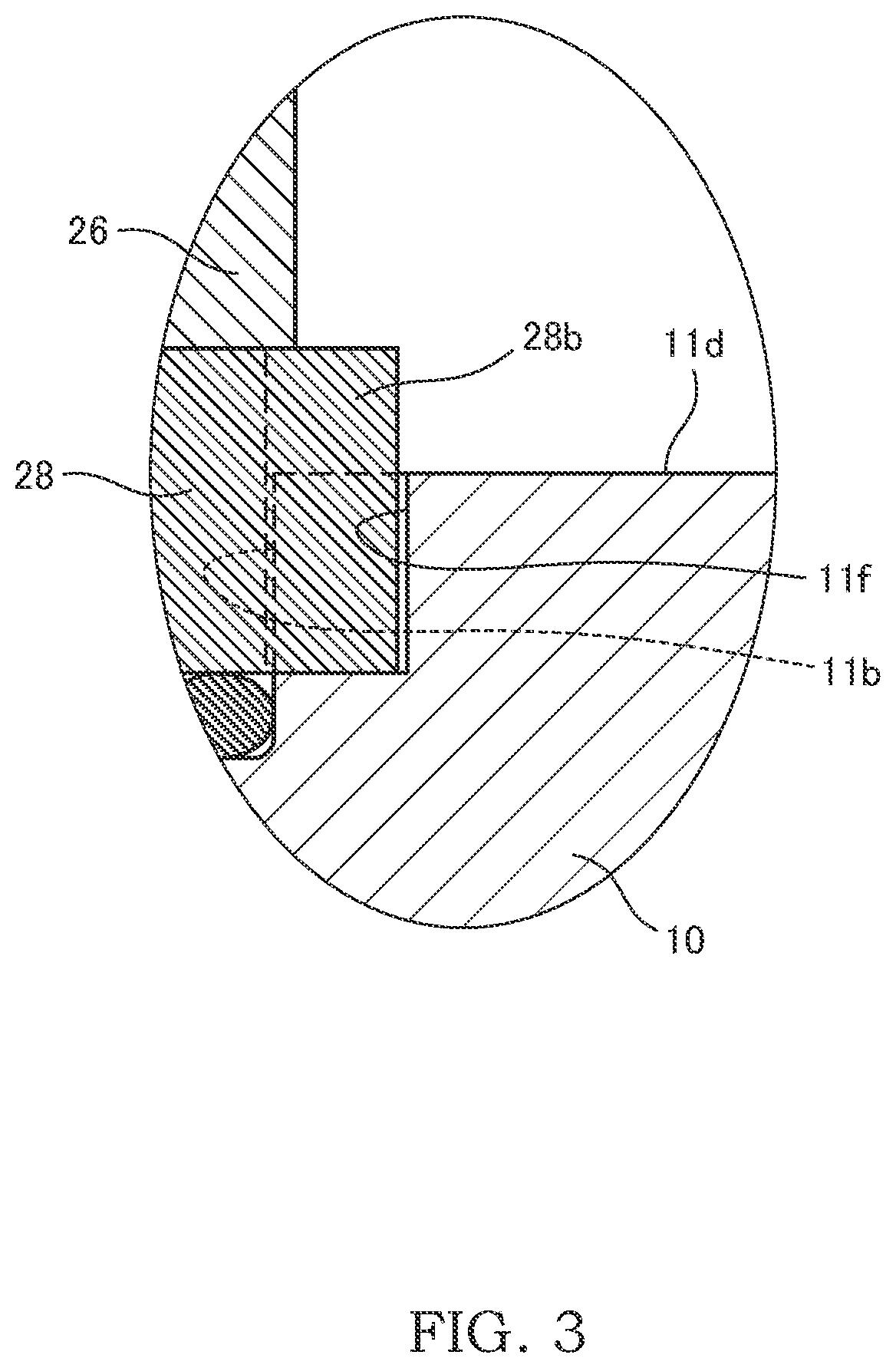

[0015]A vane pump 100 according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 3. FIG. 1 is a sectional view showing a state in which the vane pump 100 according to the first embodiment of the present invention is assembled to a driving source 50, FIG. 2 is a sectional view showing a cross-section taken along a line II-II in FIG. 1, and FIG. 3 is an enlarged sectional view showing a cross-section, in enlargement, taken along a line III-III in FIG. 2.

[0016]The vane pump 100 is used as a fluid pressure source for a fluid hydraulic apparatus, such as, for example, a power steering apparatus, a continuously variable transmission, or the like, mounted on a vehicle. Oil, aqueous alternative fluid of other type, or the like may be used as working fluid. As the driving source 50 for driving the vane pump 100, an engine or an electric motor (not shown) is used.

[0017]As shown in FIGS. 1 and 2, the vane pump 100 is provided with a pump housing 10 ...

second embodiment

[0056]Next, a vane pump 200 according to a second embodiment of the present invention will be described with reference to FIGS. 4 to 6. In the following description, differences from the above-described first embodiment will be mainly described, and components that are the same as those in the vane pump 100 according to the above-described first embodiment are assigned the same reference numerals and descriptions thereof will be omitted. FIG. 4 is a sectional view of the vane pump 200 according to the second embodiment of the present invention, FIG. 5 is a sectional view showing a cross-section taken along a line V-V in FIG. 4, and FIG. 6 is an enlarged sectional view showing a cross-section, in enlargement, taken along a line VI-VI inFIG. 5.

[0057]A basic configuration of the vane pump 200 is similar to that of the vane pump 100 according to the above-described first embodiment. In contrast to the vane pump 100 according to the above-described first embodiment in which the pump cart...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com