Brush, in Particular Toothbrush, and Method of Manufacturing the Same

a technology of toothbrushes and molded surfaces, applied in the field of toothbrushes, can solve the problems of not being able to achieve complete tightness, unable to meet the visual and design requirements of hygiene products, and the surface of intermediate products molded in this way, so as to achieve the effect of reducing plastic weigh

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

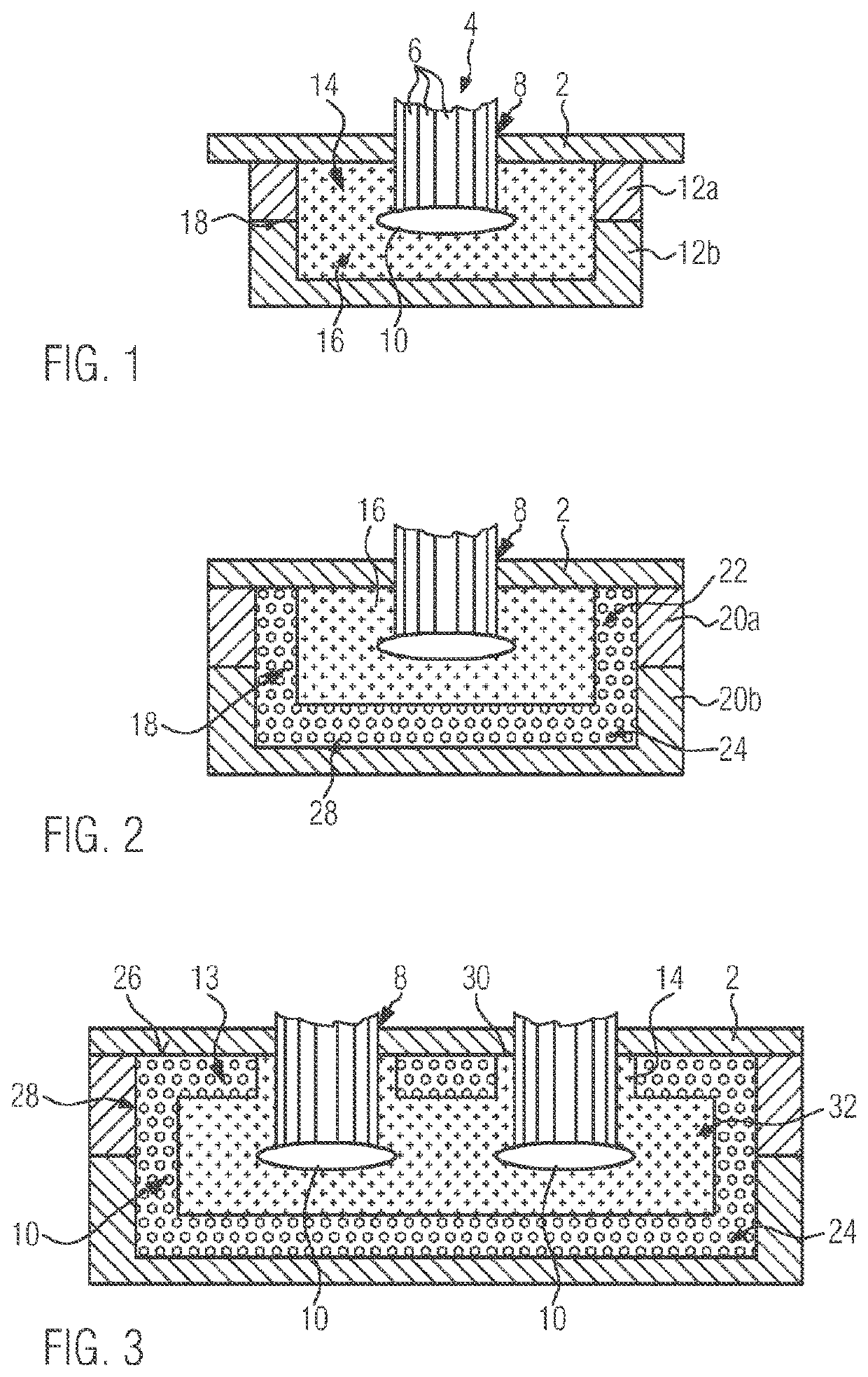

[0042]FIG. 3 shows an example of an embodiment modified with respect to FIGS. 1 and 2 after injection of the foamed plastic 24. Identical components are marked with the same reference signs. The second embodiment according to FIG. 3 differs above all in that an upper outer surface of the brush head 28 shown in cross-section, which is penetrated by the bristle bundles 4 and is marked with reference sign 26, is formed quite predominantly by the foamed plastic 24. Only an exemplary circular ring surface 30 circumferentially surrounds the bristle bundle 4, which in this case has a circular cross-section.

[0043]Accordingly, the surface regions of the brush head 28 penetrated by the bristle bundles 4 are formed by the hard component 16, but the upper outer surface 26 is otherwise predominantly formed by the foamed plastic 24. The variant shown also leads to a completely form-fitting sealing of the bristle carrier formed by the hard component 16 and identified by reference sign 32.

[0044]FIG...

first embodiment

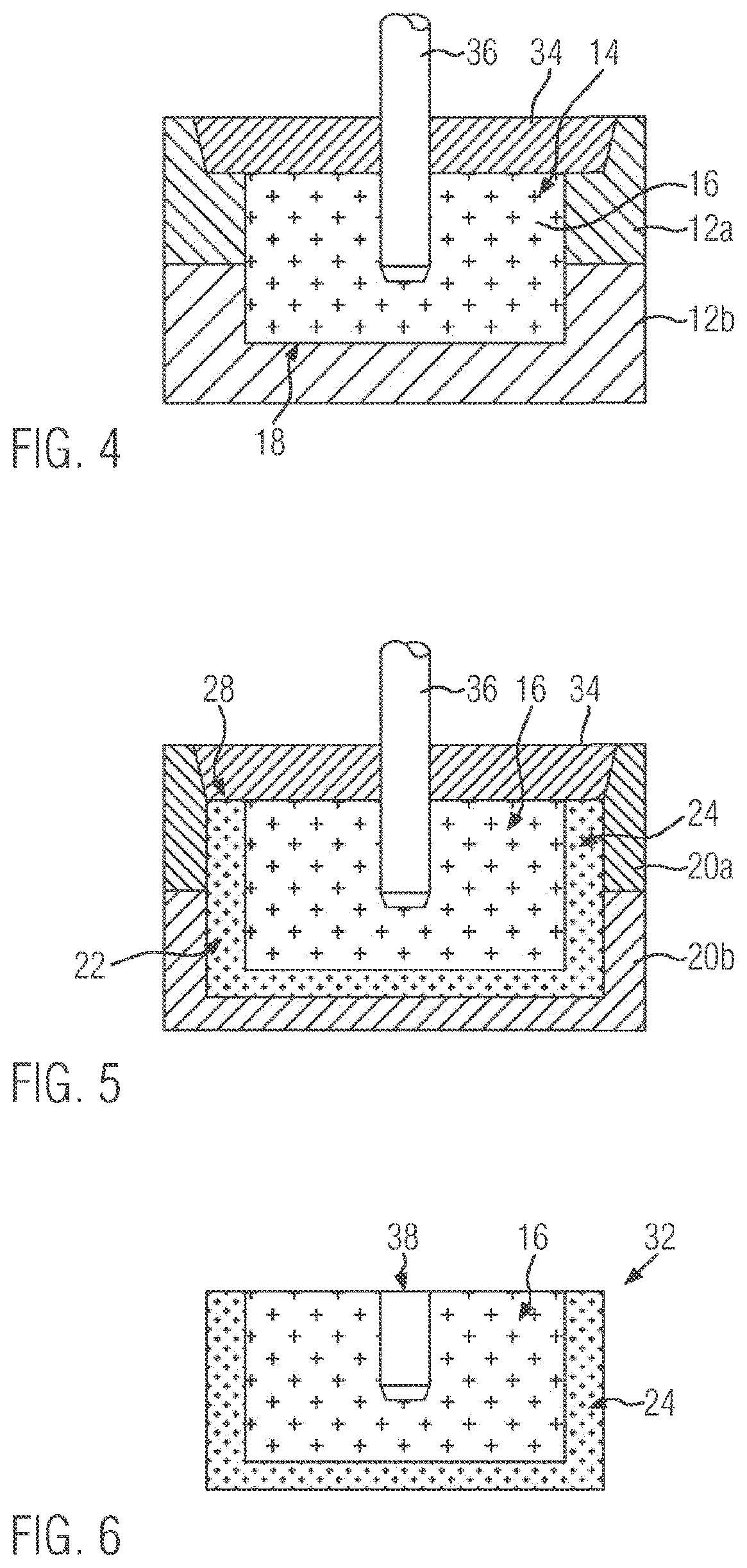

[0046]According to FIG. 5, this intermediate product 18 is transferred by displacing the pin plate 34 into the second mold cavity 22, which is dimensioned such that a free space remains between the outer surface of the intermediate product 18 and the mold cavity surfaces of the second mold cavity 22. In the present case, this free space is formed to surround the hard component 16 in the shape of a trough. Now, as in the first embodiment, foamed plastic 24 is introduced into the second mold cavity 22. The foamed plastic solidifies to form a skin, which solidifies against the surfaces bounding the second mold cavity 22. Thus, the surface penetrated by the pin 36, hereinafter referred to as the surface of the brush head 28, also exhibits a sealed surface configuration.

[0047]After ejecting the bristle carrier 32, the pin plate 34 is also removed. Instead of the pin 36, the bristle carrier 32 now has a blind hole boring 38.

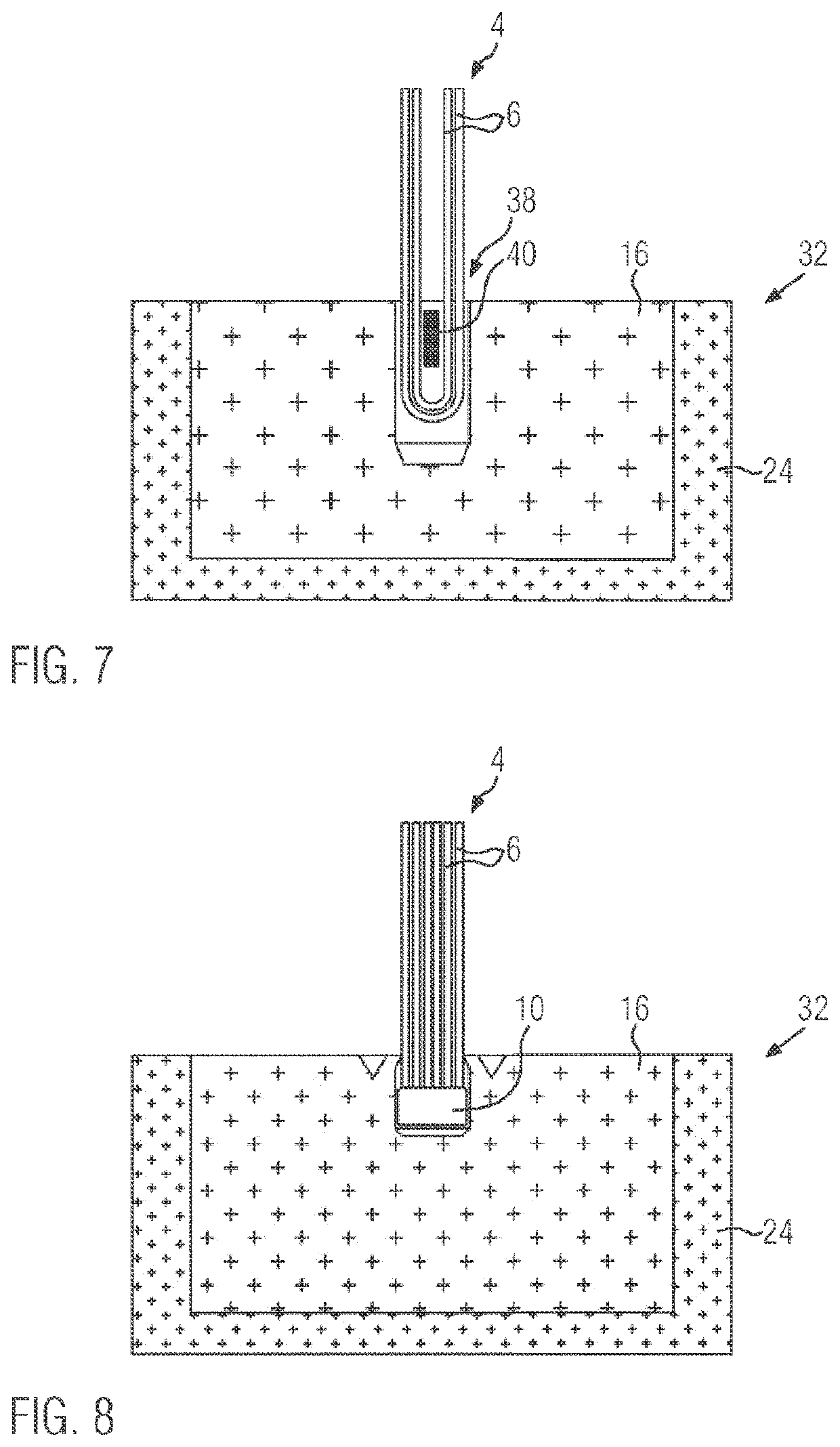

[0048]As FIG. 7 illustrates, a bristle bundle 4 may be driven int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com