Telescopic exhaust device with heat preservation and noise reduction functions

An exhaust device and function technology, applied in the field of exhaust devices, can solve the problems of the exhaust pipe not having the heat preservation effect, reducing the use effect of the equipment, and failing to achieve a better use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

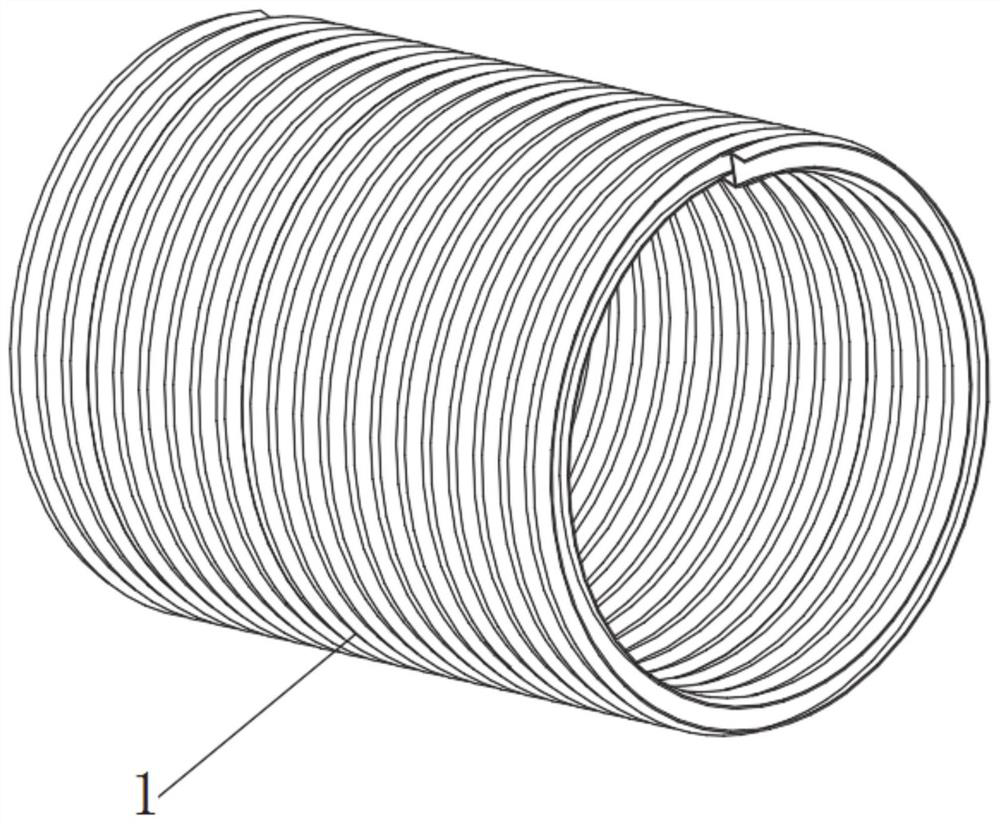

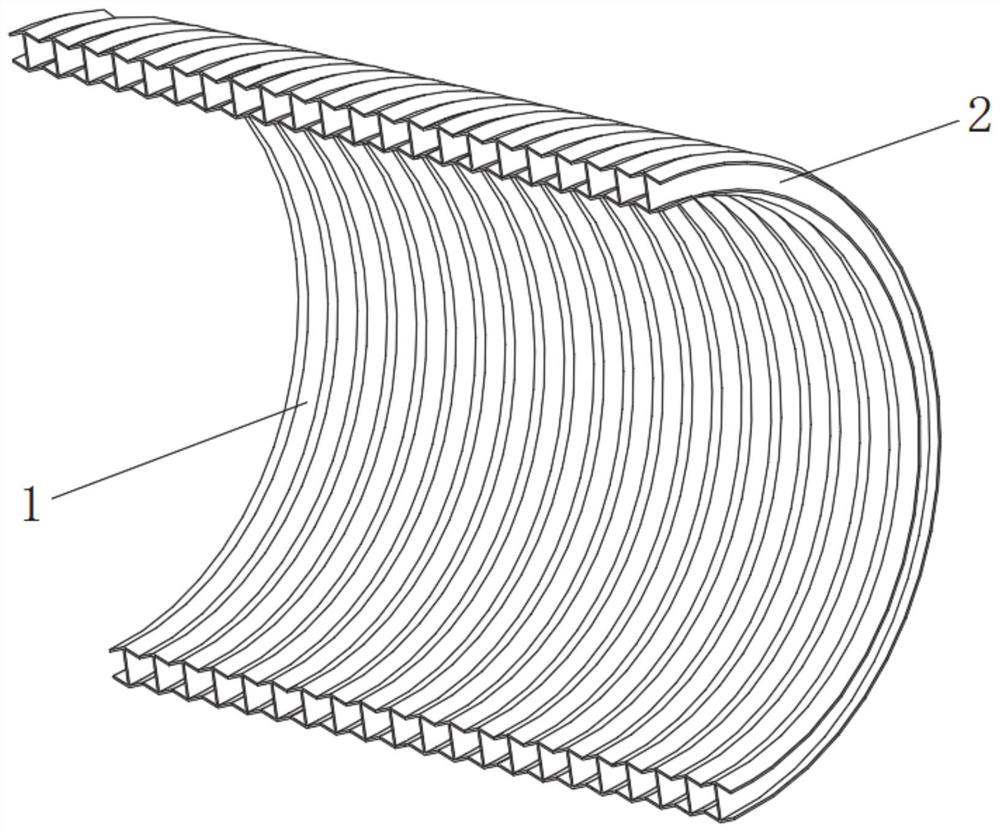

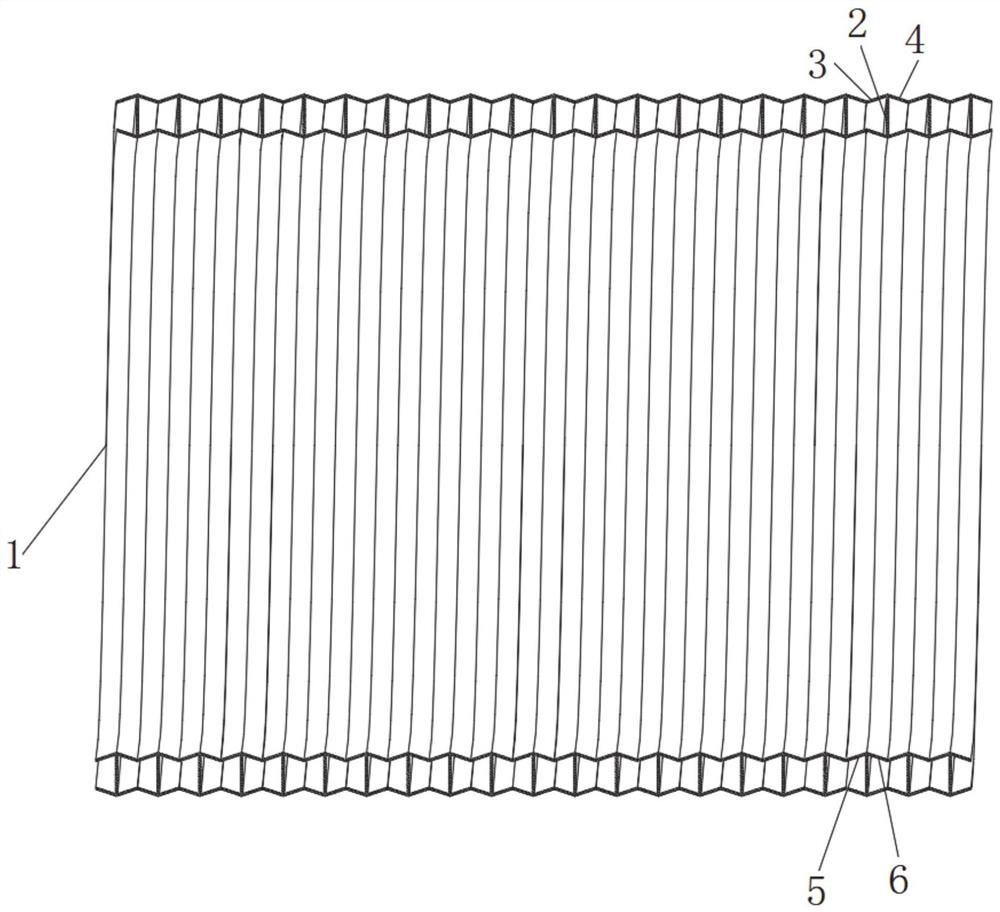

[0032] Such as Figure 1~6 As shown, a telescopic air exhaust device with thermal insulation and noise reduction functions includes an exhaust pipe body 1, and the exhaust pipe body 1 includes at least three ring-shaped telescopic joints, at least three telescopic joints are connected in sequence; the telescopic joints include Ring-shaped support ring 2, the first outer layer rotating cantilever 3 in the shape of a sheet, the second outer layer rotating cantilever 4 in the shape of a sheet, the first inner layer rotating cantilever 5 in the shape of a sheet, the second rotating cantilever in the shape of a sheet The inner layer rotating cantilever 6, the first outer layer rotating arm 3 and the second outer layer rotating arm 4 are arranged on the outer side of the support ring 2, the first inner layer rotating arm 5 and the second inner lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com