Gas Compression Process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

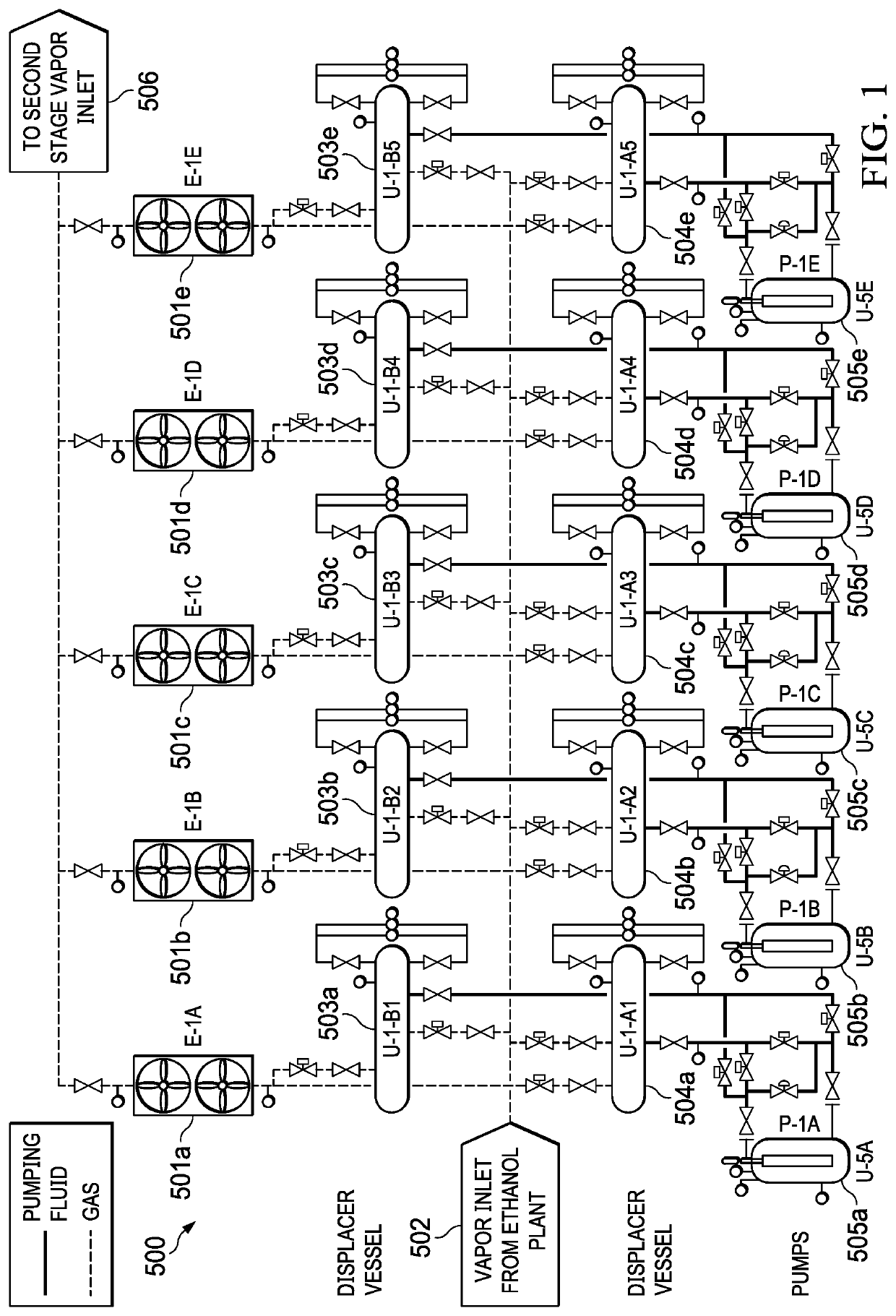

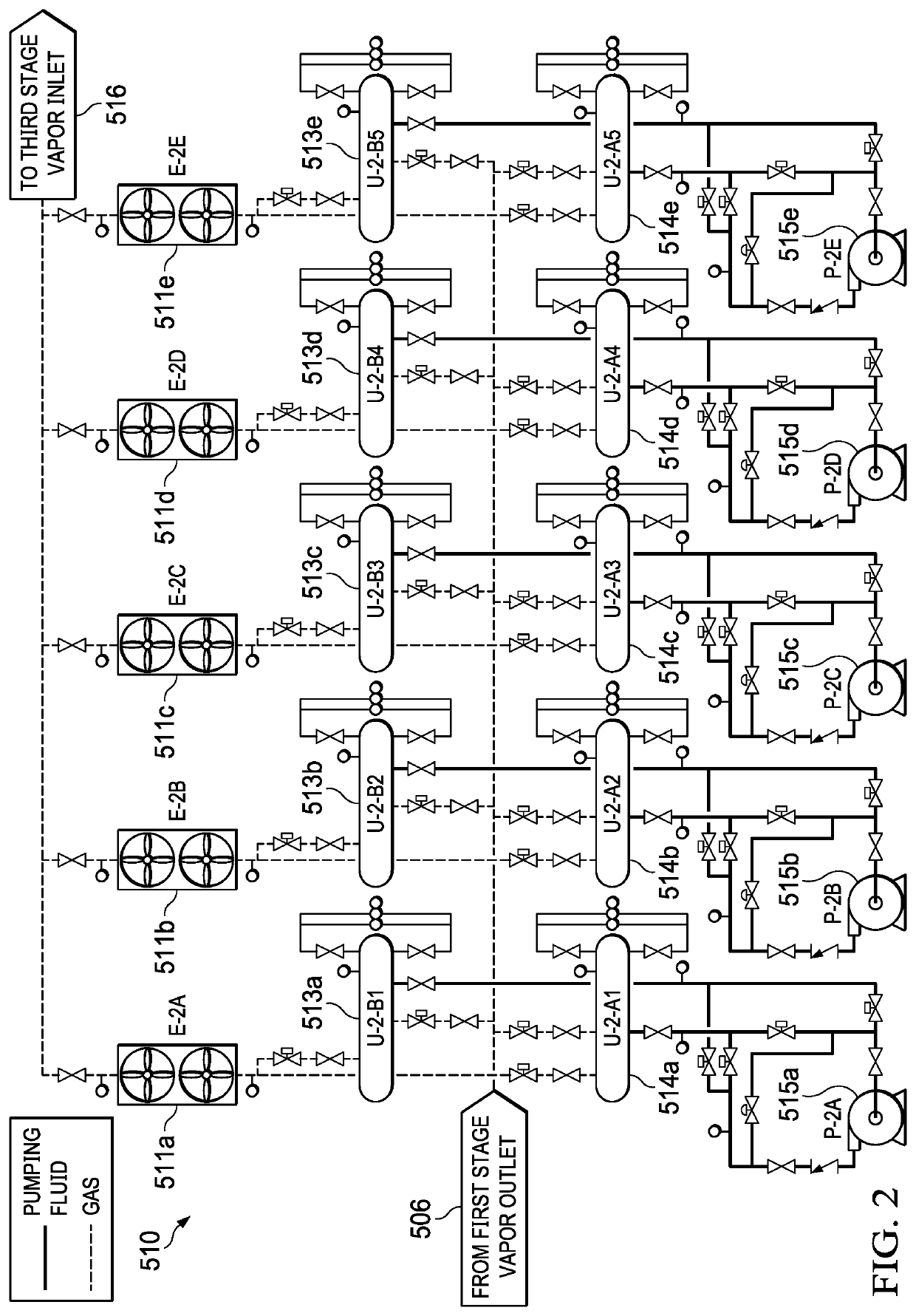

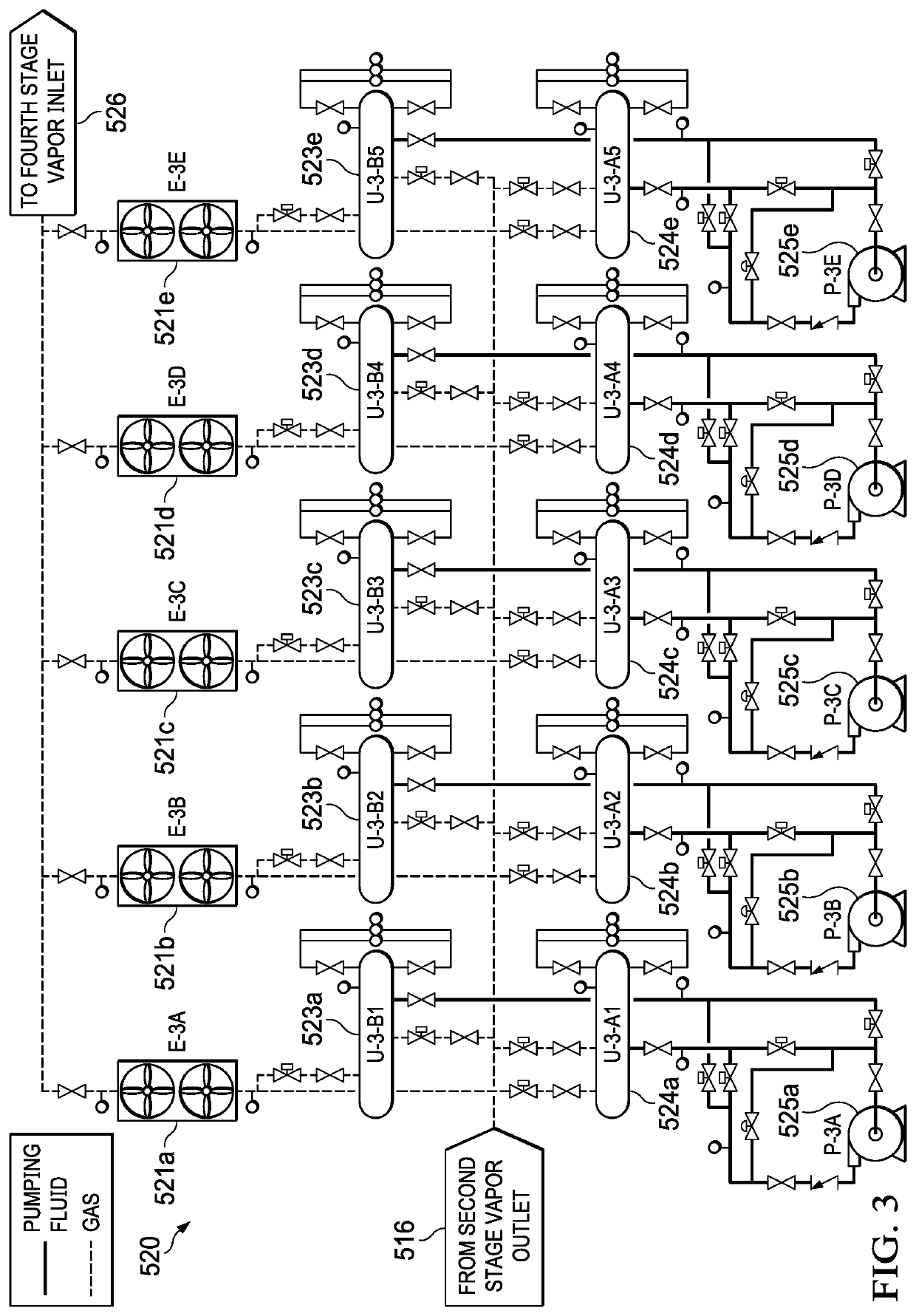

[0003]An example embodiment may include a method for compressing gas comprising compressing a gas at a first stage compressor to create a first compressed gas, cooling the first compressed gas, compressing the first compressed gas at a second stage compressor to create a second compressed gas, cooling the second compressed gas, compressing the second compressed gas at a third stage compressor to create a third compressed gas, cooling the third compressed gas, compressing the third compressed gas at a fourth stage compressor to create a fourth compressed gas, cooling the fourth compressed gas, condensing the fourth compressed gas into a liquified gas, collecting the liquified gas, pressuring the liquified gas, delivering the liquified gas into a gas line.

[0004]A variation of the example embodiment may include the gas being CO2. The first stage compressor may be a plurality of pairs of displacement vessels each pair having a dedicated pump. The second stage compressor may be a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com