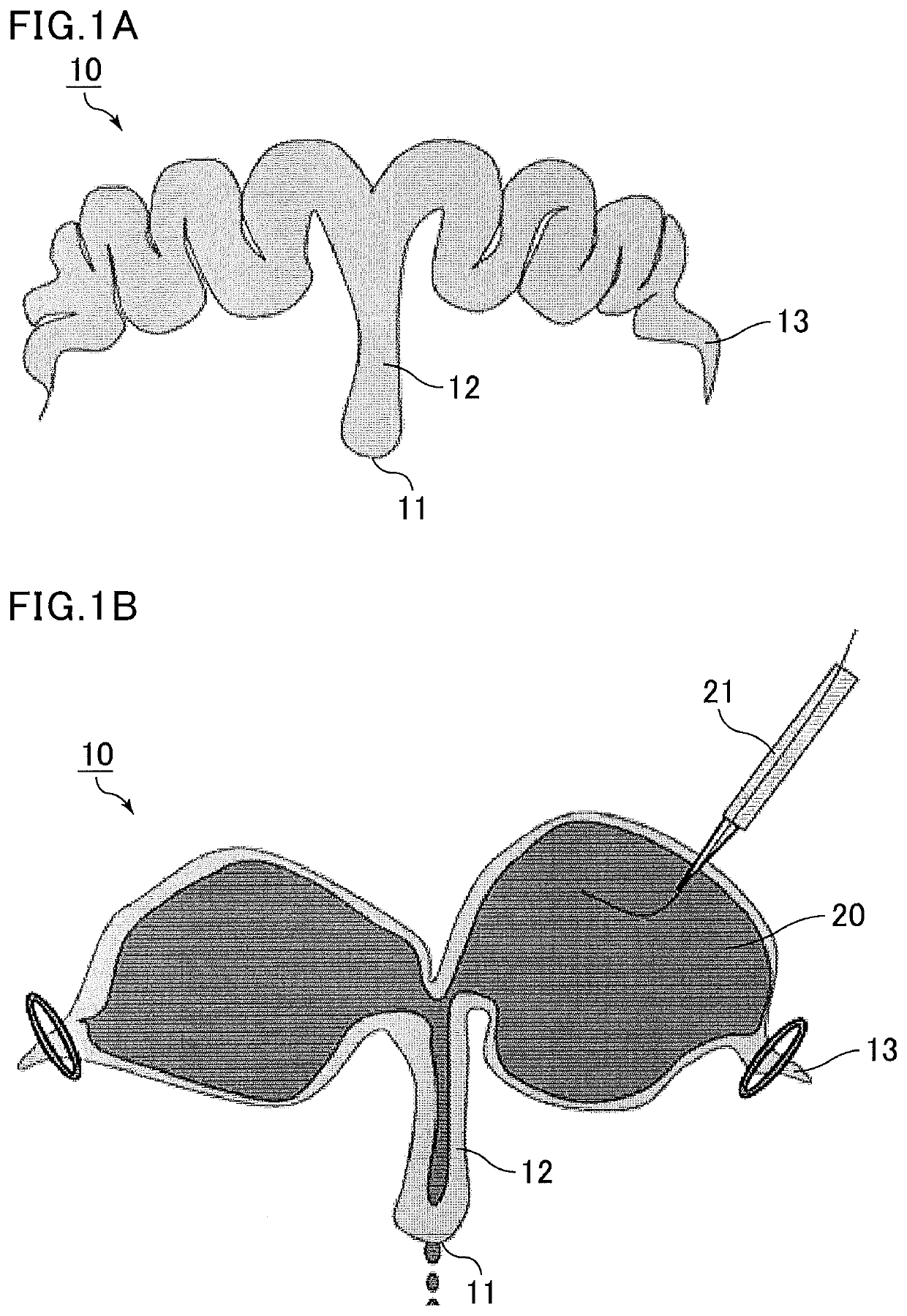

Sealing agent for genitals

a technology for sealing agents and genitals, which is applied in the direction of adhesive types, surgical procedures, pharmaceutical delivery mechanisms, etc., can solve the problems of fetus hypoplastic lung, poor prognosis, and high mortality of newborns, and achieve the effect of stopping bleeding and inhibiting amniotic fluid leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

[0149]An autoclave was charged with ethylene glycol (15.5 parts) and potassium hydroxide (3.8 parts). After purging with nitrogen (oxygen concentration in the gas phase: 450 ppm), the mixture was dehydrated in vacuum at 120° C. for 60 minutes.

[0150]Subsequently, a mixture of ethylene oxide (784.5 parts) and 1,2-propylene oxide (200 parts) was injected with pressure at 100° C. to 130° C. over about 10 hours, followed by reaction at 130° C. for 3 hours, whereby a liquid-state crude polyether having an oxyethylene unit content of 80% was obtained.

[0151]The liquid-state crude polyether (1000 parts) was placed in the autoclave which was purged with nitrogen (oxygen concentration in the gas phase: 450 ppm), followed by addition of ion-exchanged water (30 parts) and then synthesized magnesium silicate (sodium content: 0.2%) (10 parts). After another purging with nitrogen, the mixture was stirred at a stirring rate of 300 rpm at 90° C. for 45 minutes. Next, filtration was performed under ni...

production example 2

[0153]An autoclave was charged with propylene glycol (42.2 parts) and potassium hydroxide (3.8 parts). After purging with nitrogen (oxygen concentration in the gas phase: 450 ppm), the mixture was dehydrated in vacuum at 120° C. for 60 minutes.

[0154]Subsequently, a mixture of ethylene oxide (800.0 parts) and 1,2-propylene oxide (157.8 parts) was injected with pressure at 100° C. to 130° C. over about 10 hours, followed by reaction at 130° C. until the volatile content was 0.1% or less, whereby a liquid-state crude polyether was obtained.

[0155]The liquid-state crude polyether was treated with synthesized magnesium silicate as in Production Example 1, whereby a random coadduct (B1-2) of ethylene oxide and 1,2-propylene oxide to propylene glycol was obtained.

[0156]The (B1-2) had a number average molecular weight of 1800, an oxyethylene unit content of 84%, and an alkali metal and / or alkaline earth metal content of 0.03 mmol / kg.

production example 3

[0157]An autoclave was charged with propylene glycol (362 parts) and potassium hydroxide (3.8 parts). After purging with nitrogen (oxygen concentration in the gas phase: 450 ppm), the mixture was dehydrated in vacuum at 120° C. for 60 minutes.

[0158]Subsequently, 1,2-propylene oxide (632 parts) was injected with pressure at 100° C. to 130° C. over about 10 hours, followed by reaction at 130° C. until the volatile content was 0.1% or less, whereby a liquid-state crude polyether was obtained.

[0159]The liquid-state crude polyether was treated with synthesized magnesium silicate as in Production Example 1, whereby a 1,2-propylene oxide adduct (B2-1) to propylene glycol was obtained.

[0160]The (B2-1) had a number average molecular weight of 210, an oxyethylene unit content of 0%, and an alkali metal and / or alkaline earth metal content of 0.04 mmol / kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| storage modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com